Feed vehicle capable of alarming material shortage

A feeding car and material shortage technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of machine tool material shortage, mold cracking, economic loss, etc., and achieve the effects of avoiding safety accidents, avoiding air pressure, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

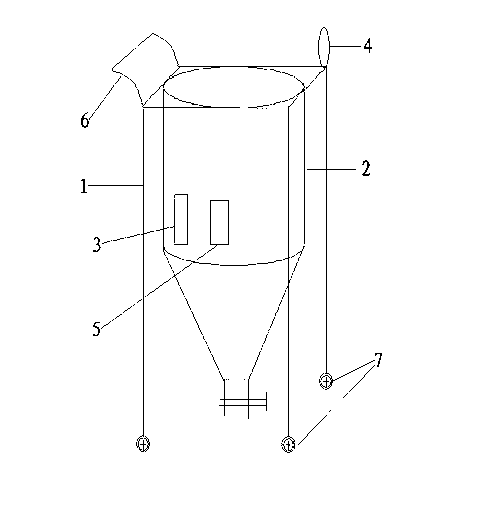

[0014] Such as figure 1 As shown, the present invention provides a charging vehicle capable of alarming material shortage, including a vehicle frame 1 and a hopper 2 . The bottom of the four legs of the vehicle frame 1 is equipped with casters 7, which can make the feeding cart move freely; the vehicle frame 1 and the hopper 2 are fixed; the hopper 2 is provided with a load cell 3, which can sense And display the weight of the remaining powder in the hopper 2; the top of the frame 1 is provided with an alarm 4, and the alarm 4 can give an alarm when the weight of the powder in the hopper 2 is lower than the limit set weight.

[0015] The hopper 2 is also provided with a timing controller 5, which has an infrared remote control function, and can remotely stop the corresponding stamping machine tool.

[0016] Before use, the operator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com