Powder dumper

A pourer and powder technology, applied in the field of tobacco machinery, can solve the problems that ordinary masks cannot achieve effective human protection and human injury.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

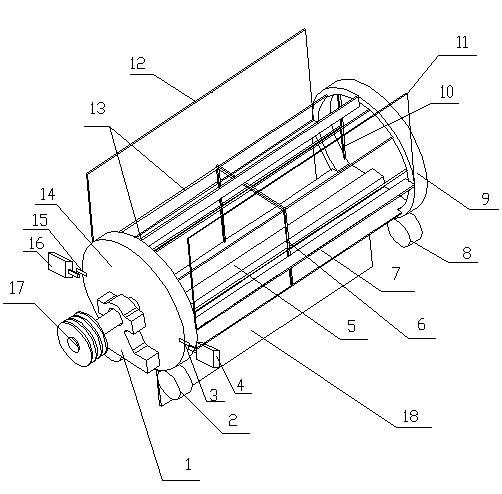

[0011] The present invention will be further described below in conjunction with accompanying drawing.

[0012] Such as figure 1 As shown, the powder dumper includes a second contact 3, a second limit switch 4, a bottom support rod 5, a second limit frame 6, a bottom plate 7, a front guide rail 9, a first limit frame 10, a powder guard Plate Ⅰ11, powder guard plate Ⅱ12, connecting rod 13, rear guide rail 14, first contact 15, first limit switch 16, pulley 17 and wiper plate 18, the bottom of front guide rail 9 and rear guide rail 14 are respectively provided with left and right symmetrical brackets A frame body is formed between the roller group I8 and the idler roller group II2, the front guide rail 9 and the rear guide rail 14 through welding connecting rods 13, and the first limiting frame 10 and the second limiting frame 6 are respectively upright welded to the front end of the frame body The inner wall of the front guide rail 9 and the middle part of the frame body; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com