Basement exterior wall post-cast strip construction structure

A technology for basement exterior walls and post-pouring belts, applied to underwater structures, infrastructure engineering, artificial islands, etc., can solve the problems of multiple processes, time influence, and increased concrete volume, and achieve convenient technology, high safety, and The effect of increased stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

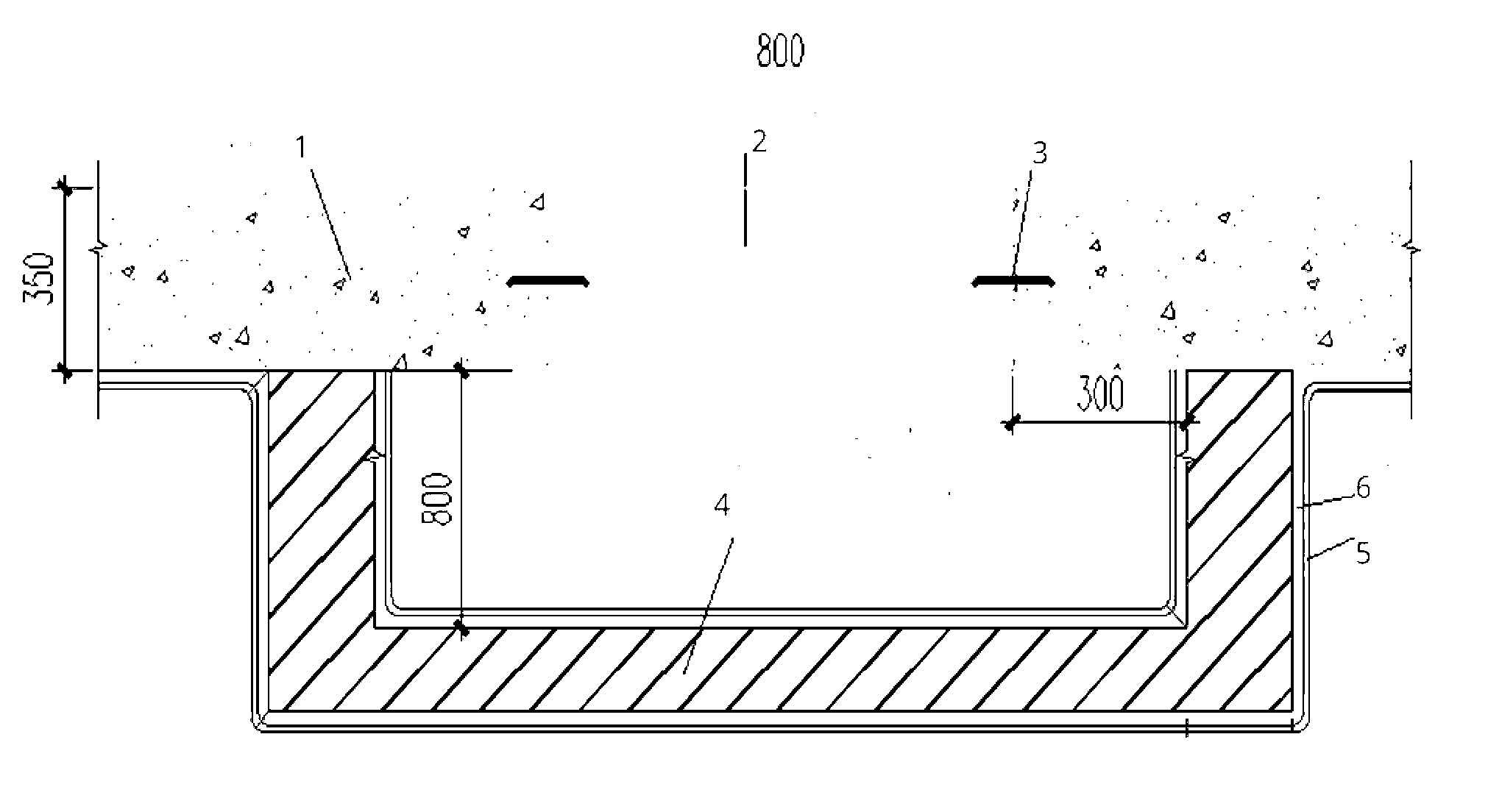

[0013] Combine below figure 1 Specifically explain the construction structure of the post-pouring belt of the basement exterior wall. A masonry 4 of shale solid bricks is built on the outside of the basement exterior wall 1 corresponding to the position of the post-pouring strip 2. The masonry 4 is equipped with steel bars. shaped structure. A steel plate waterstop 3 is provided on the side adjacent to the post-casting belt of the basement exterior wall.

[0014] The surface of the masonry 4 is double-faced with 20mm cement mortar 6 . The outside of the masonry is laid with SBS waterproof coiled material 5 on the cement mortar. The thickness of the basement exterior wall is 350mm, and the width of the post-casting strip is 800mm. The inner side of the masonry is 0.8m away from the basement exterior wall, the left and right sides of the masonry are 300mm away from both sides of the post-casting belt, and the thickness of the masonry is 240mm.

[0015] The construction proce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com