Network digital straight-bar direct-reading roof separation instrument

A roof abscission instrument, direct reading technology, applied in mining equipment, mining equipment, earth-moving drilling and other directions, can solve the problems of low precision, lack of data analysis function, high cost, improve safety management level, observe and measure The effect of convenient and convenient centralized and unified management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1: A mine 3 # The burial depth of the return air trough in the coal seam 3101 working face is about 240m, the section width of the roadway is 5.2m, the height is 4.2m, and the length is 1.0km. The roof of the channel is made of carbonaceous mudstone and siltstone, and the small structure is developed in the channel. The surrounding rock is soft and broken, and the stability of the surrounding rock of the roadway is poor, which is a type IV unstable surrounding rock.

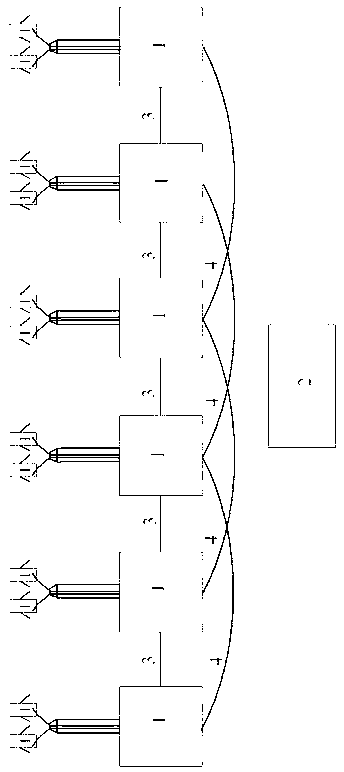

[0025] A digital straight-rod direct-reading roof separation instrument is arranged in the tunnel, such as figure 1 , figure 2 as shown,

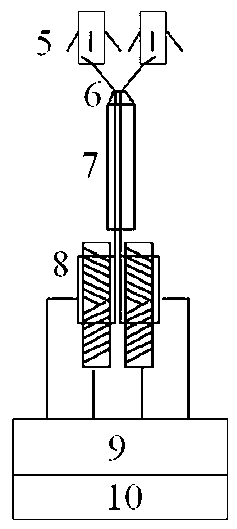

[0026] The present embodiment comprises sensor network node 1 and wireless base station 2, and sensor network node 1 is made of base point anchor head 5, measuring rope 6, vertical measuring cylinder 7, segmented digital capacitive displacement sensor 8, processor 9 and direct-reading monitor 10 and other components, wherein the light control element of t...

Embodiment 2

[0028] Example 2: A mine 3 # The buried depth of the first mining face of the coal seam is about 100m, the roof is relatively complete, and the surrounding rock of the roadway is Class II stable surrounding rock. A digital straight-rod direct-reading roof delamination instrument is arranged in the roadway. The total number of digital straight-rod direct-reading wireless sensor network nodes 1 is 22, the working voltage of the wireless base station 2 is 127V, there are 2 base stations, and the monitoring time is 8 In July, the actual monitoring effect was good, and the display values of the direct-reading monitor 10 and the wireless base station 2 did not change, that is, the rock formations at these 22 places had no separation layers inside and outside the bolt anchorage range. Others are with embodiment 1.

Embodiment approach 3

[0029] Implementation mode 3: A mine 3 # The coal seam 3104 working face is an isolated island working face, the surrounding rock of the roadway is unstable surrounding rock of type V, and the roof is relatively broken. The digital straight-rod direct-reading roof delamination instrument is arranged in the working face. The communication distance between the sensor network nodes 1 of the digital straight-rod direct-reading roof delamination instrument is 20m, and the total number of wireless sensor network nodes 1 is 9. The working voltage of base station 2 is 380V, there are 2 base stations, and the monitoring time is 12 months. The actual monitoring effect is good. There are 4 positions of abscission within the anchoring range of the anchor bolt, and there are positions of abscission outside the anchoring range of the anchor bolt. 3 places. Others are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com