On-line pressure fast plugging nail for fire hose and fast plugging method

A technology of fire hose and plugging method, which is applied in the direction of pipes/pipe joints/pipes, mechanical equipment, pipe components, etc., can solve the problem of inability to achieve online fast and effective plugging, etc., and achieves easy implementation and operation. Simple and fast plugging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

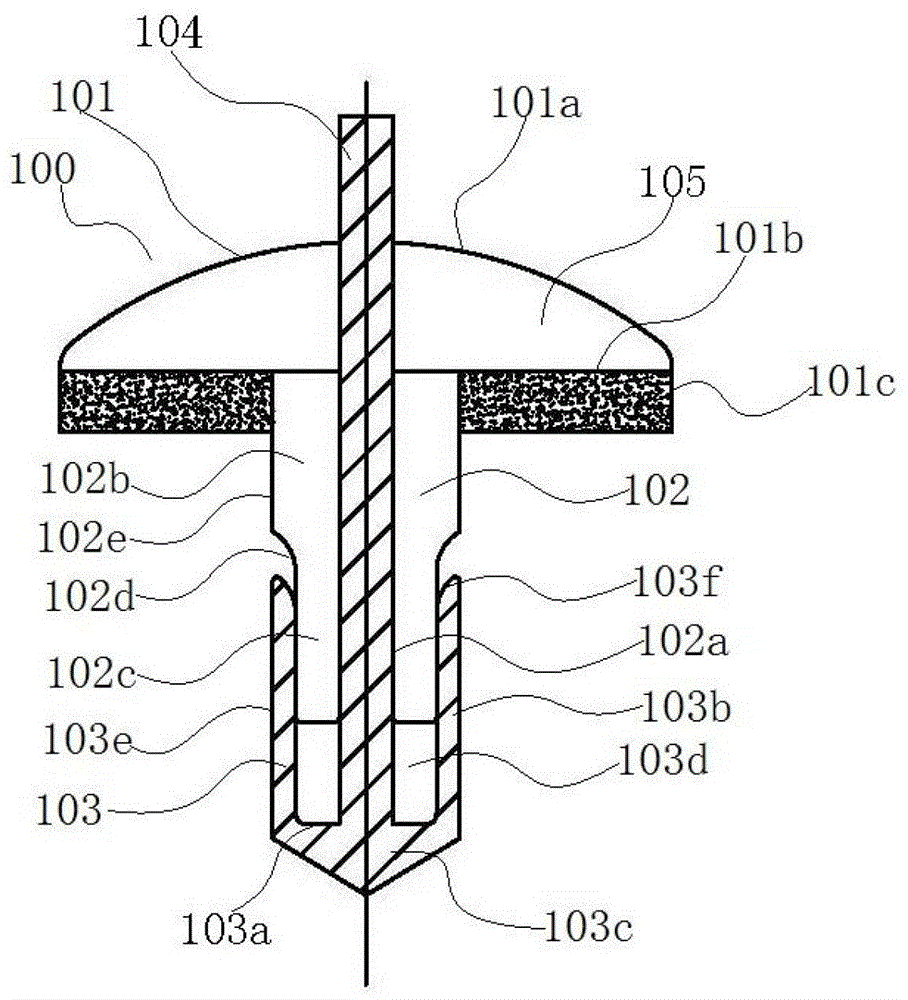

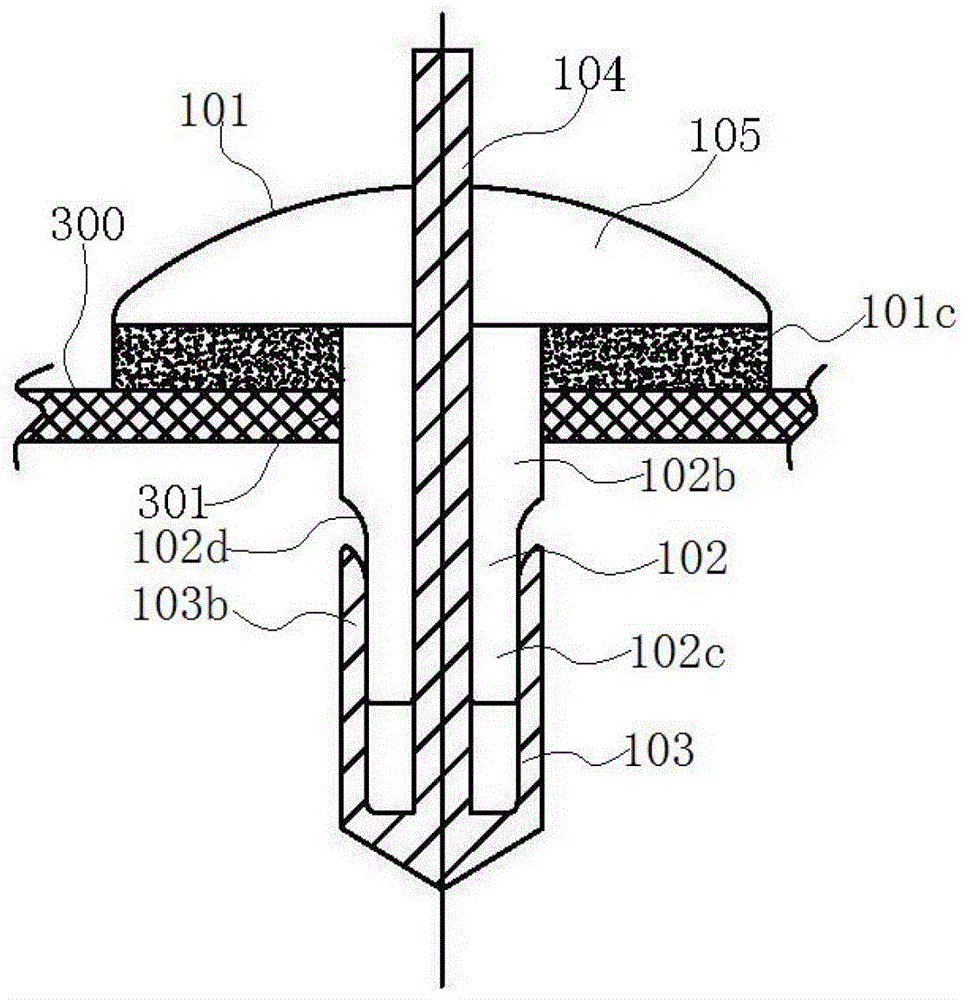

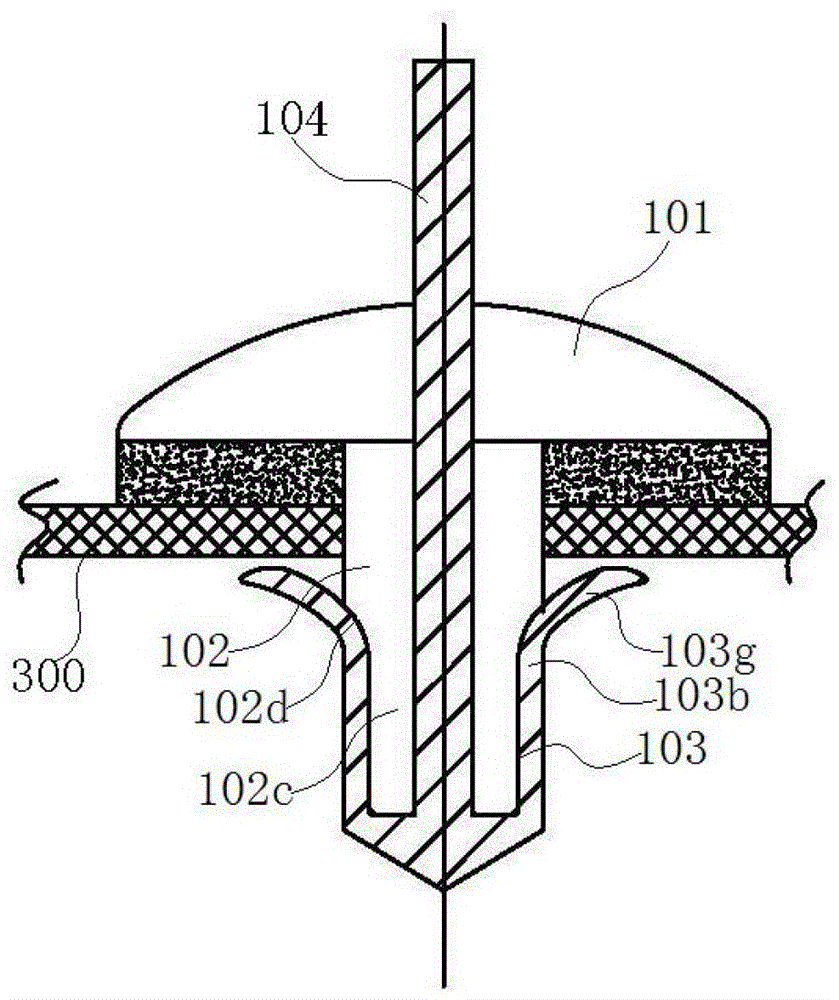

[0042] see figure 1 , The leak plugging nail 100 provided in this example mainly includes two parts: a nail shaft 104 and a leak plugging sleeve 105 . The cross-section of the plugging sleeve 105 is "T" shape, and consists of a plugging cover 101 and a plugging rod 102 arranged on the plugging cover 101. The plugging cover 101 is used to compress and seal the outside of the leakage port, and Make the plugging rod 102 on it pass through the leakage port; and the nail rod 104 is movably inserted in the plugging sleeve 105 along the extension direction of the plugging rod, and its front end is covered with a plugging cap 103. When moving in the leak sleeve, the plugging cap 103 cooperates with the plugging rod in the plugging sleeve, and the port side wall of the plugging cap is driven by the plugging rod to deform as a whole facing the inner wall of the pipeline (that is, the direction of the leakage port). Compress and seal the inside of the leak over the leak.

[0043] When ...

example 2

[0068] see Figure 4 , The leak plugging nail 200 provided in this example mainly includes two parts: a nail shaft 204 and a leak plugging sleeve 205 . The cross section of the plugging sleeve 205 is "T" shape, mainly formed by the plugging cover 201 and the plugging rod 202 arranged on the plugging cover, the leak plugging cover 201 is used to compress and seal the outside of the leakage port, And make the plugging rod 202 on it pass through the leakage port. The nail rod 204 is movably installed in the leak plugging sleeve along the extension direction of the leak plugging rod 202, and a guide block 203 is arranged on the head thereof. When the nail rod moves in the leak plugging sleeve, the guide block 203 and the free end 202b of the leak plugging rod Cooperate, drive the free end of the plugging rod to deform as a whole facing the inner wall of the pipeline (that is, the direction of the leakage port), and make the deformation part compress from the inner side of the lea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com