Measuring device for spring washer elasticity test and measuring method thereof

A technology of spring washers and measuring devices, applied in measuring devices, mechanical measuring devices, mechanical devices, etc., can solve the problems of complicated plots and complex structures, achieve standard consistency, get rid of random errors, and test quickly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

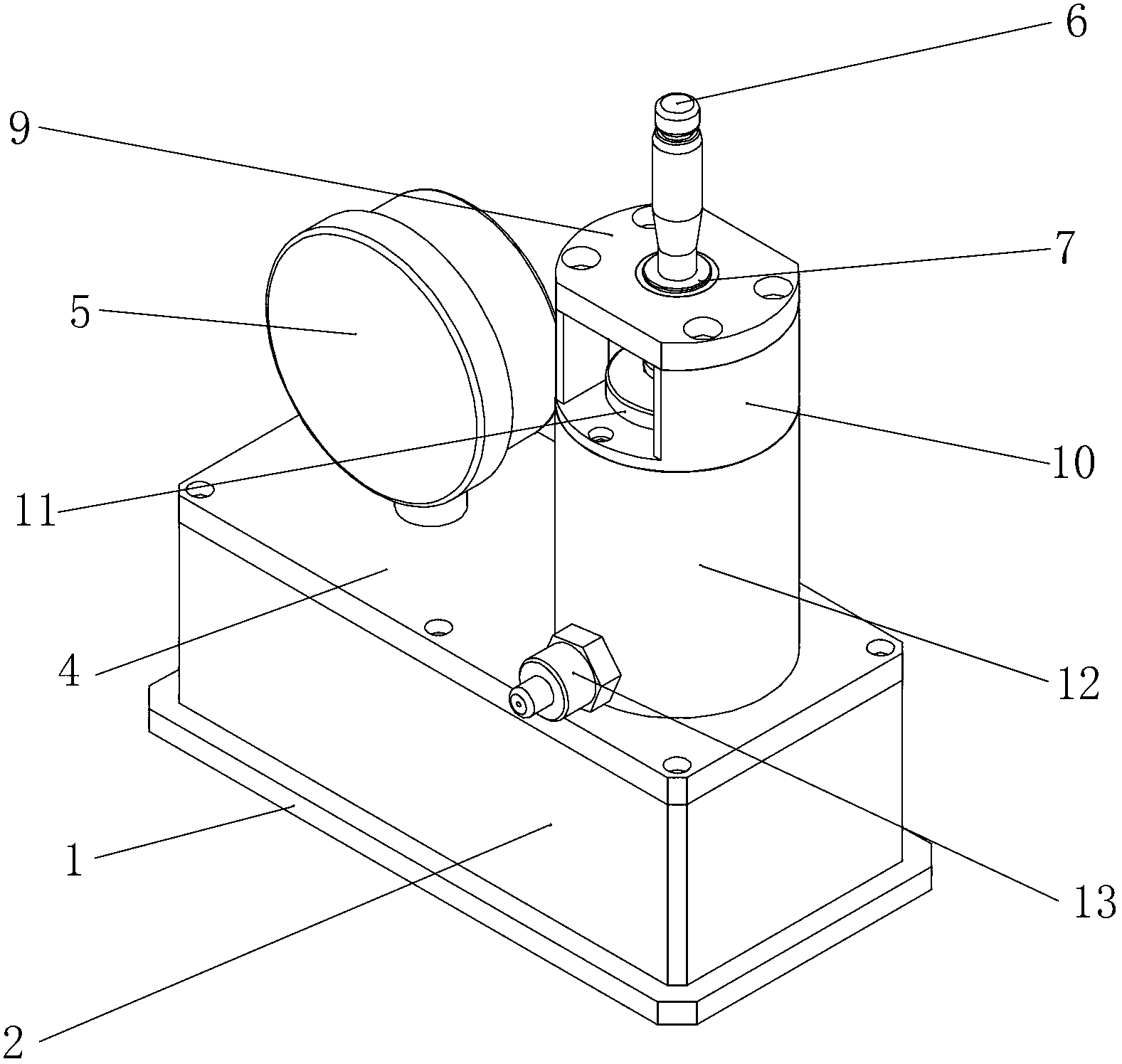

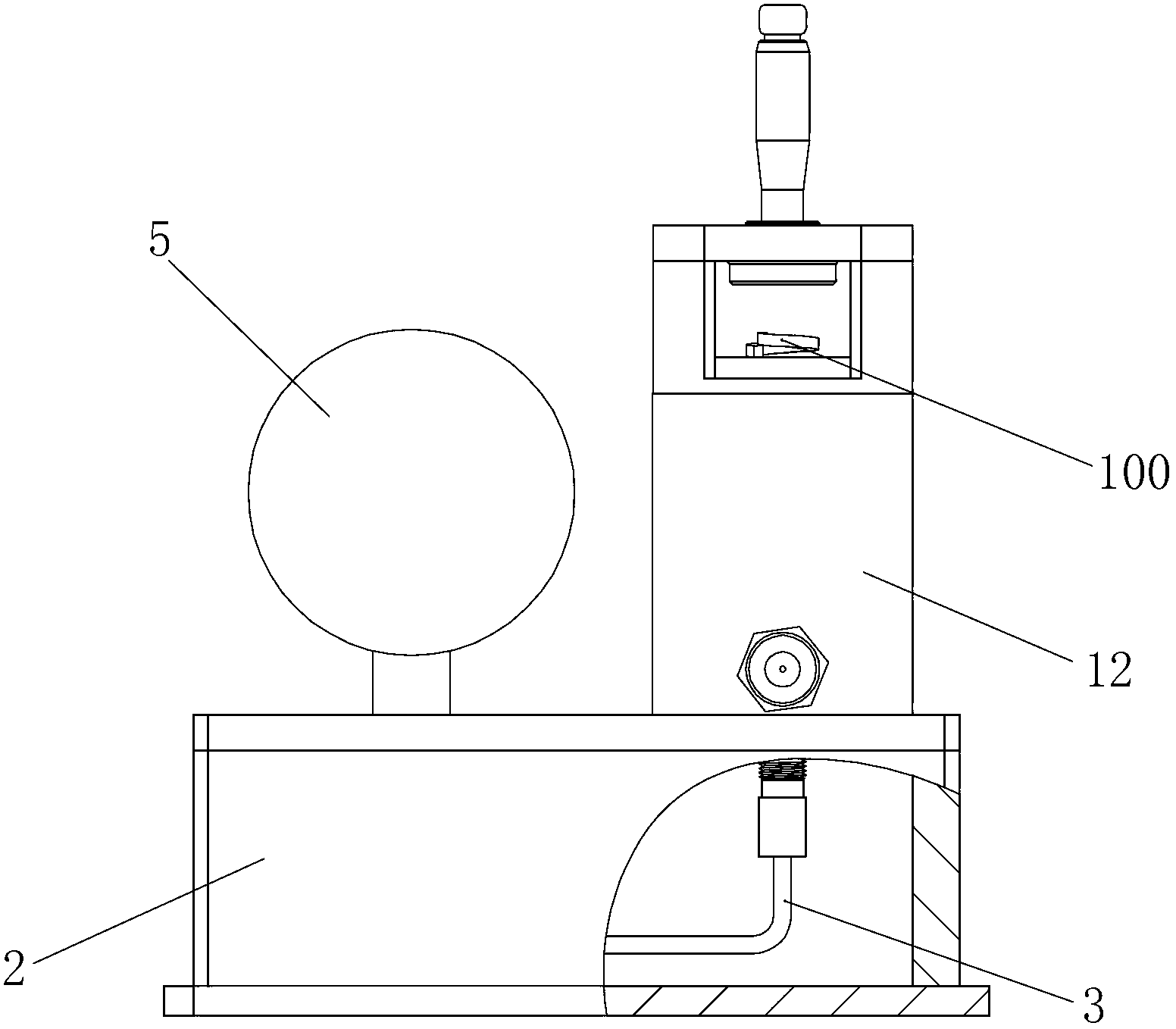

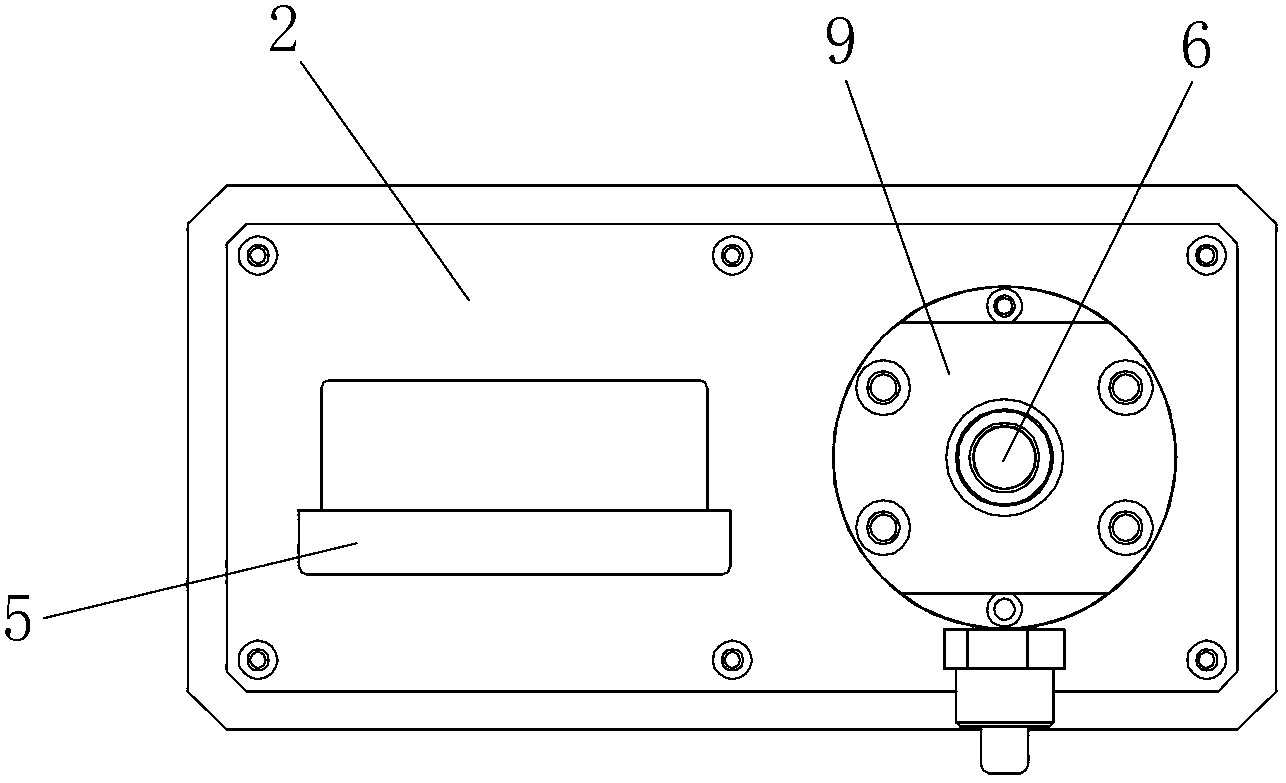

[0034] Such as Figure 1 to Figure 4 The shown measuring device for spring washer elasticity test includes a base, a loading unit, a pressure measuring unit and a height measuring unit. The loading unit includes an oil cylinder 12, an oil rod 11, a connecting sleeve 10 and a top plate 9, and the oil cylinder 12 is installed vertically on On the base, the oil inlet of the oil cylinder 12 is connected to the hydraulic oil pump through the joint 13, and the connecting sleeve 10 is installed on the top of the oil cylinder 12 through screws. There are two notches 10a provided on the side of the connecting sleeve 10, and the two notches 10a are symmetrically distributed. The top plate 9 is installed on the top of the connecting sleeve 10 by screws to cover the upper opening of the connecting sleeve 10. There is a central hole, the oil rod 11 is installed vertically in the oil cylinder 12, it can move up and down under the drive of the oil cylinder 12, and can extend into the barrel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com