Field emission display and fabrication method thereof

A display and field emission technology, which is applied in cold cathode manufacturing, electrode system manufacturing, electrode assembly manufacturing, etc., can solve problems such as inability to grow CNTs, difficult to synthesize CVD stable structures, etc., and achieve low price, simple manufacturing, and stable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

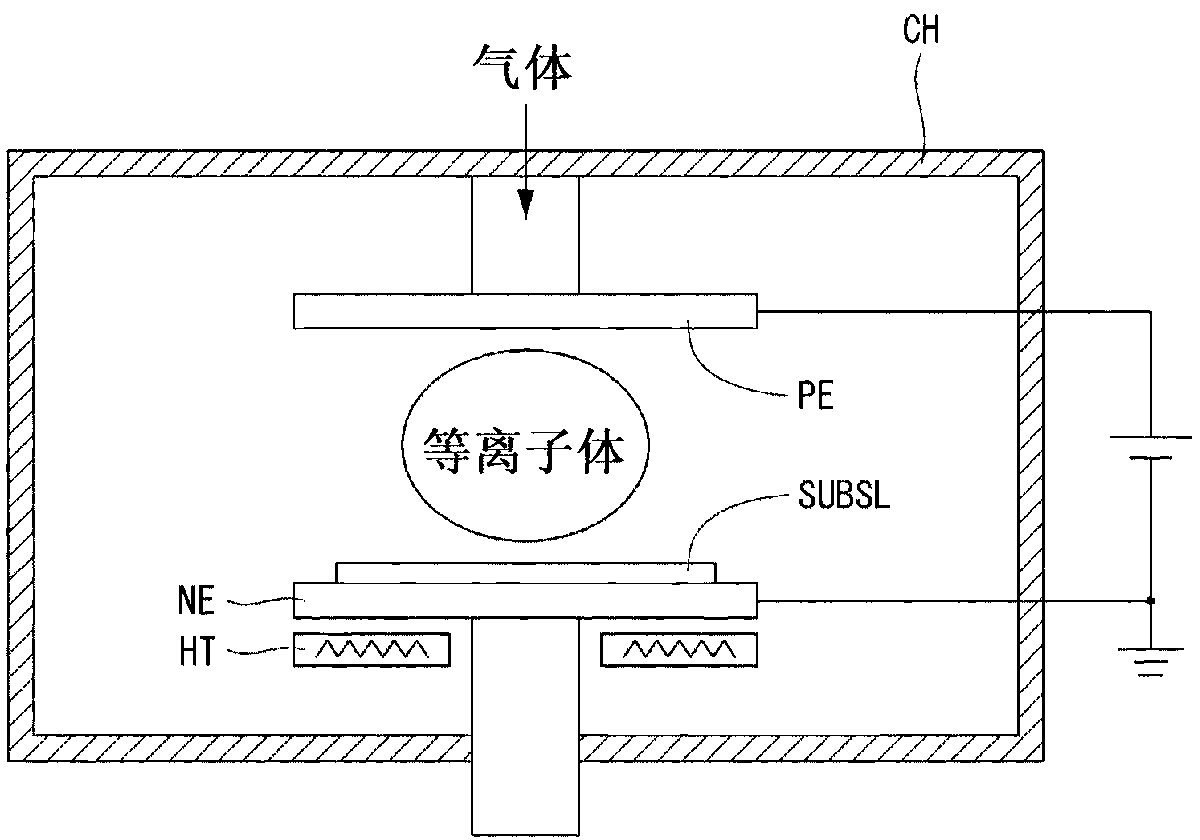

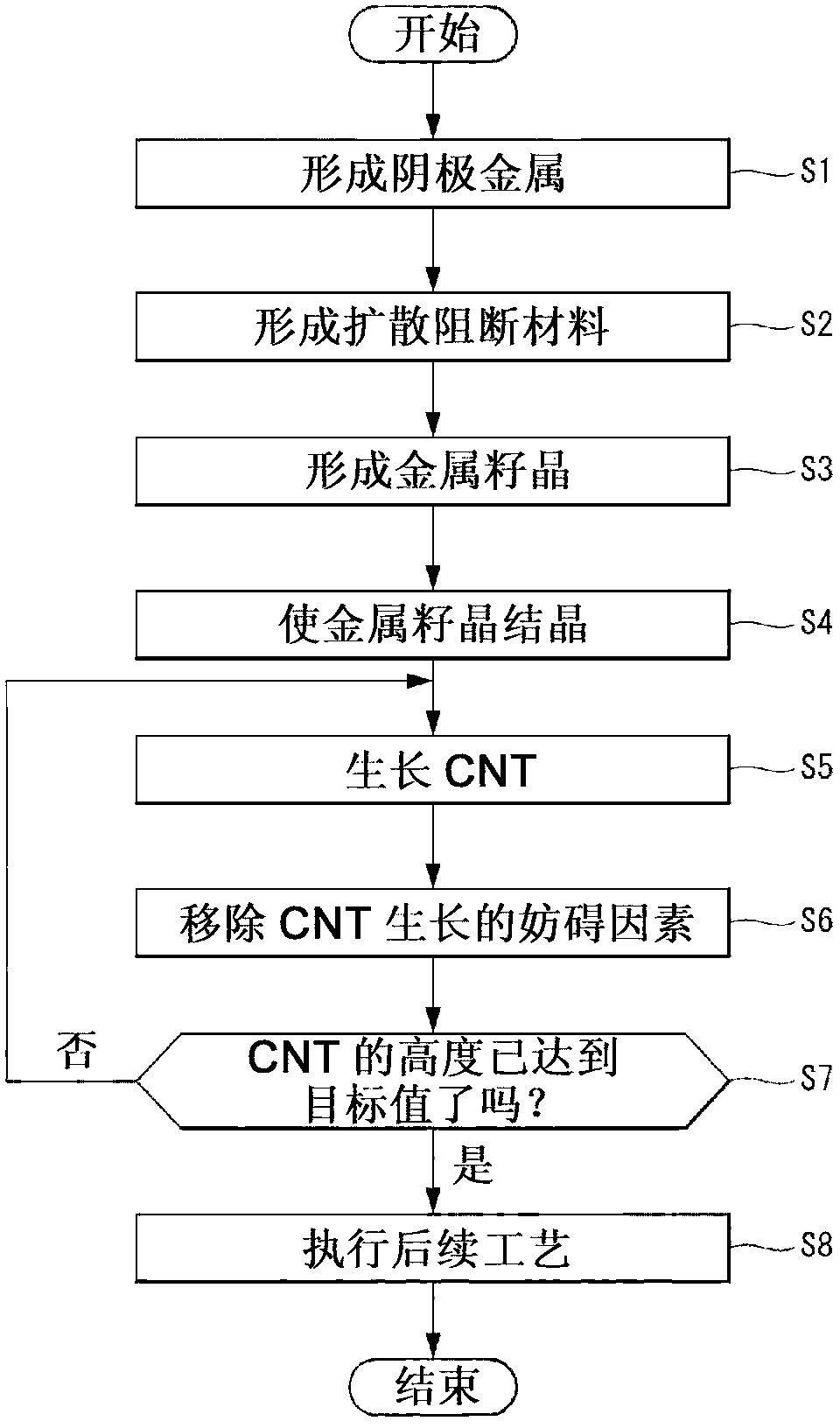

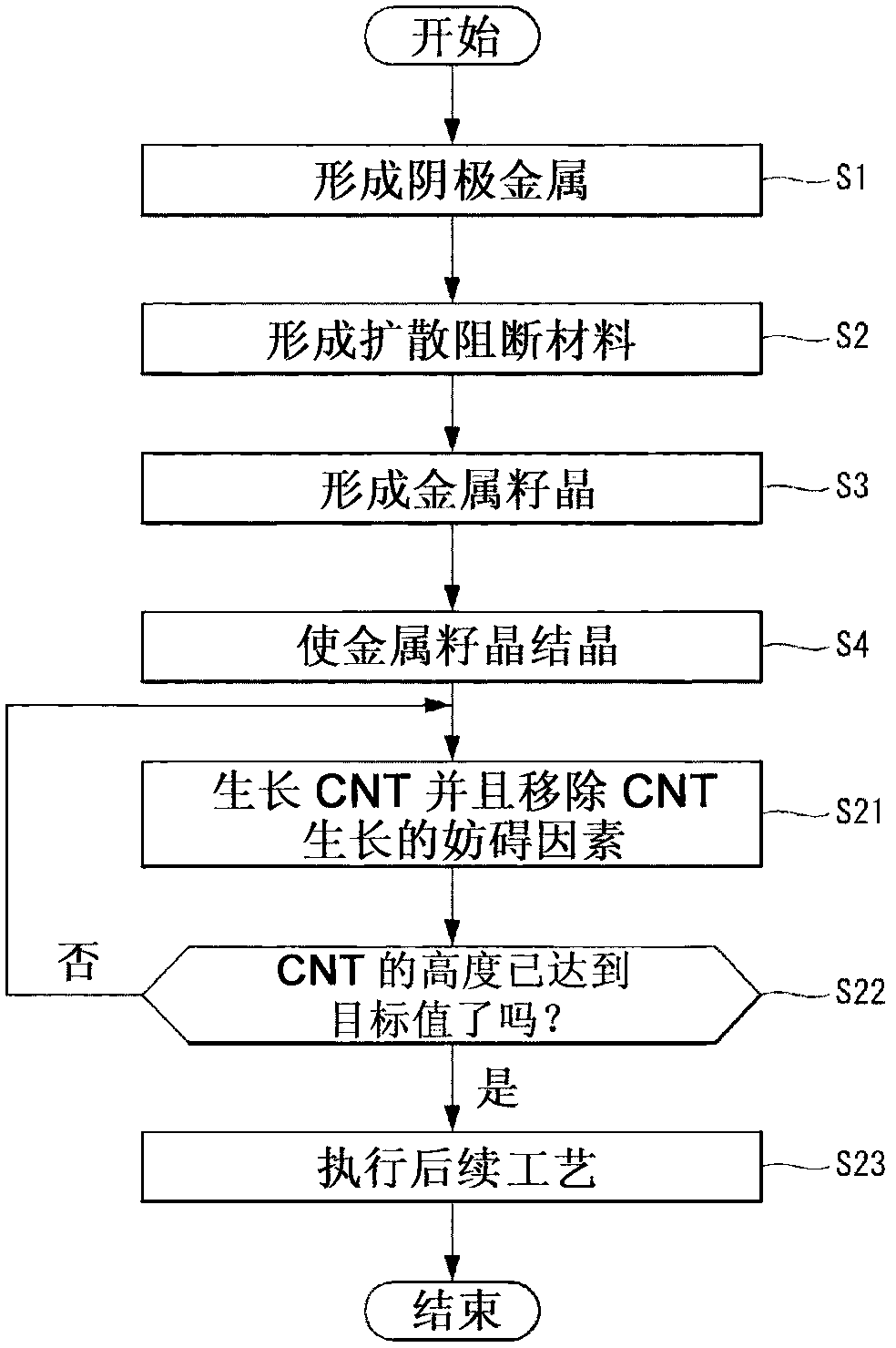

[0039] The field emission display (FED) of the present invention includes: an upper plate including an anode electrode and phosphor powder formed on an upper substrate; a lower plate facing the upper plate, and on the upper plate There is a vacuum space gap between the board and the lower board, the lower board includes a plurality of thin film patterns formed on a lower substrate; and a spacer is provided between the upper board and the lower board to Maintain the vacuum space gap.

[0040] The lower plate may include: a cathode electrode including one or more metals selected from molybdenum (Mo), aluminum (Al), copper (Cu), chromium (Cr) and alloys thereof, and formed on the On the substrate; a diffusion barrier layer, the diffusion barrier layer includes titanium (Ti), tungsten (W), tantalum (Ta) and alloys of the three metals, silicon and any one or mixture of silicon compounds, and formed on the cathode electrode; a metal seed crystal formed on the diffusion blocking lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com