Cereal cooling dryer

A dryer and grain technology, applied in dryers, dryers, refrigerators, etc., can solve the problems of inability to remove grain moisture, inability to remove grain pile moisture, inability to kill grain insects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

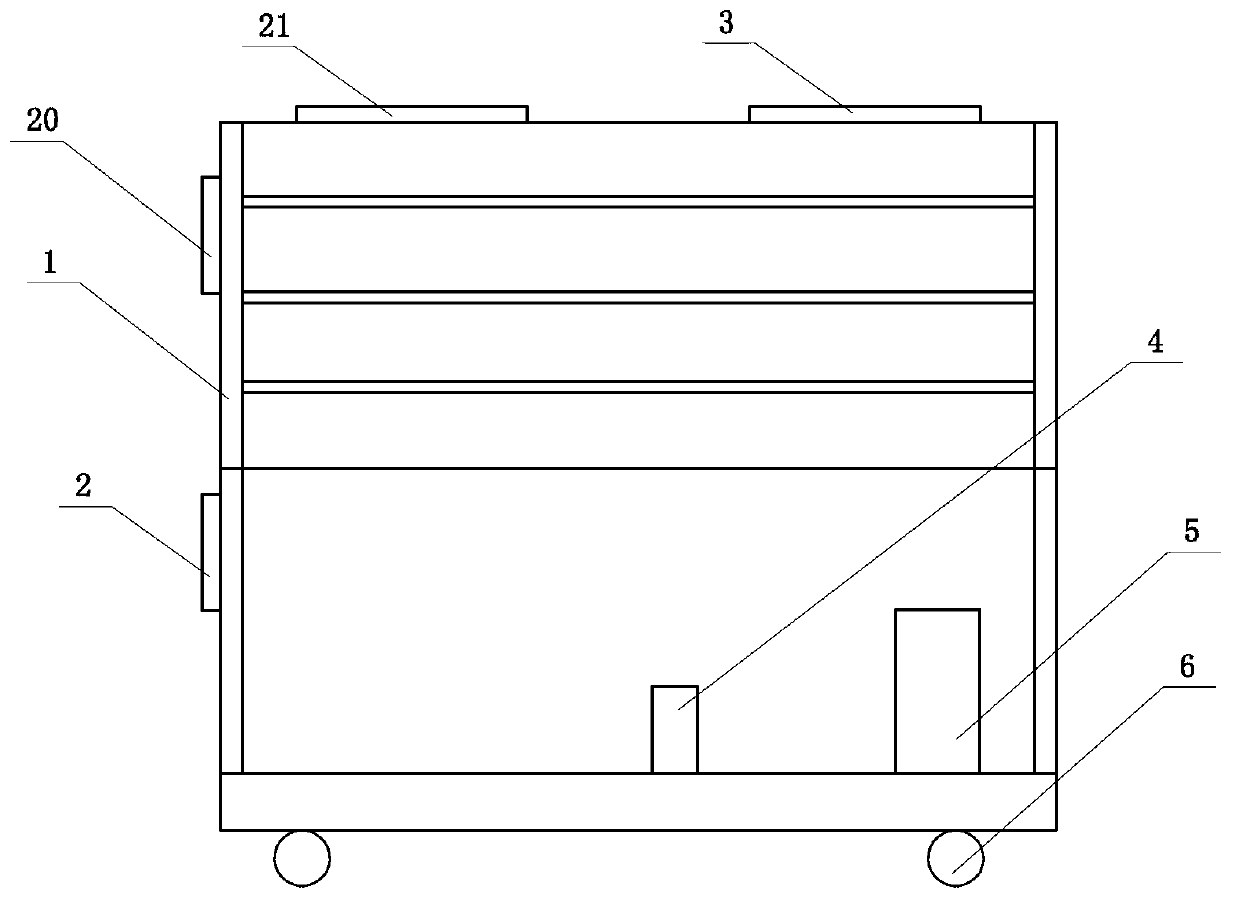

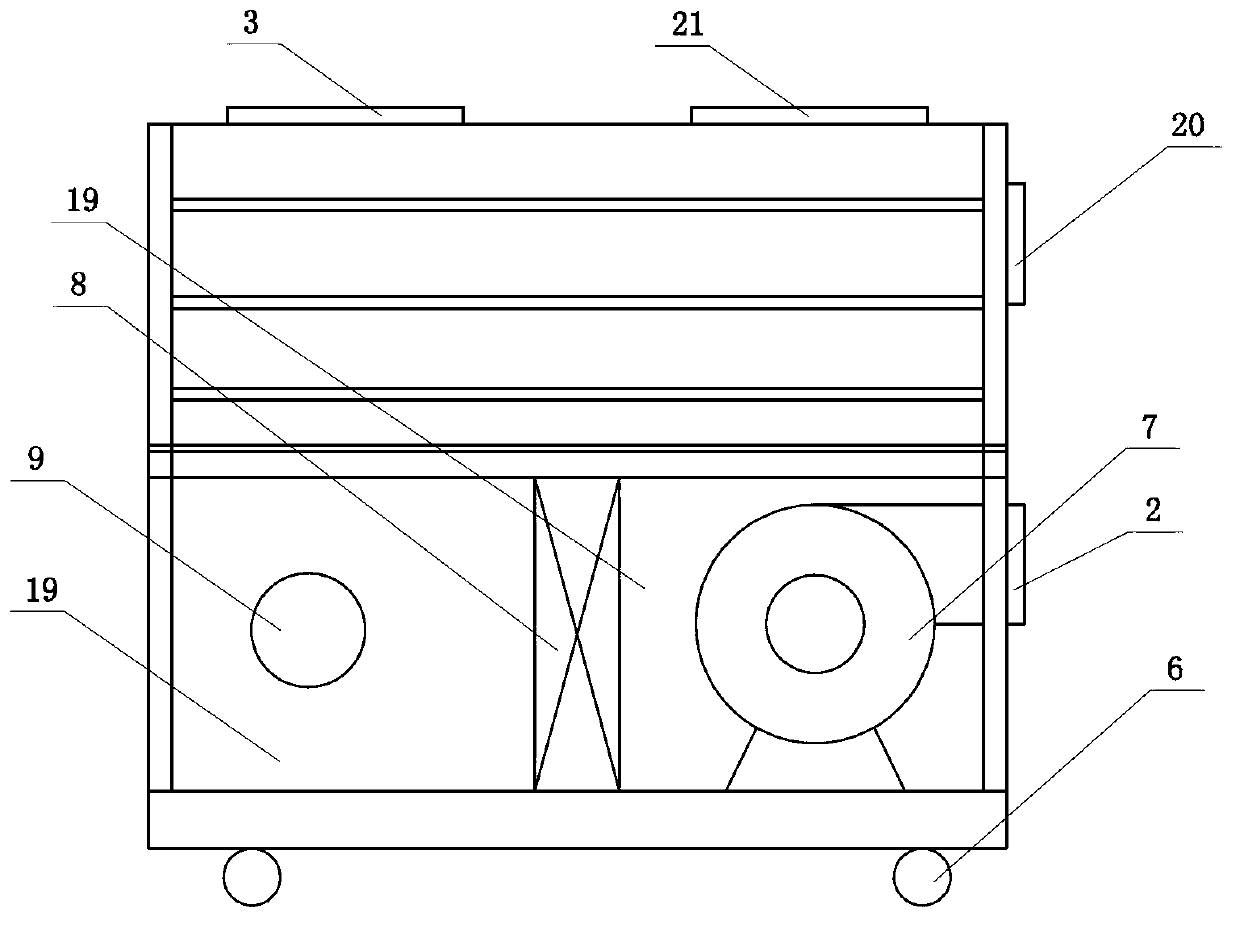

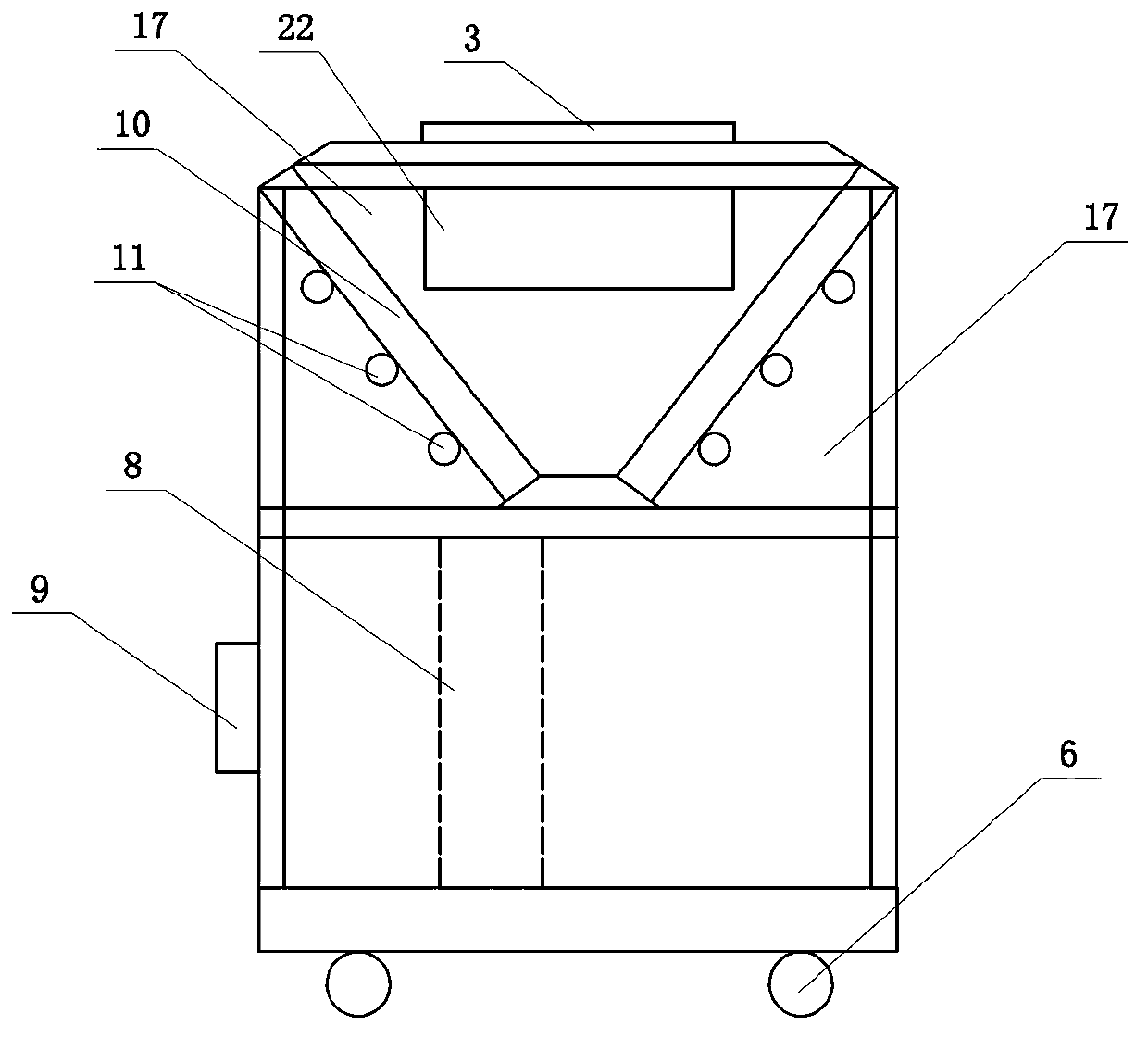

[0017] combined with figure 1 to attach Figure 4 , a grain cooling dryer, which includes a casing 1 and a power supply, the casing 1 is provided with a controller 20; the casing 1 is also provided with a first heat exchanger chamber 19, a second heat exchanger chamber 17 and A working unit, the working unit includes a first compressor 5, a first heat exchanger 8, a second heat exchanger 10, a throttling component 16 and a four-way valve 18; the first heat exchanger 8 is installed In the first heat exchanger chamber 19, the first air supply port 2, the first air return port 9 and the first air outlet for exhausting the air in the first heat exchanger chamber 19 are also installed in the first heat exchanger chamber 19. To the first blower 7 in the drying room; the second heat exchanger 10 is installed in the second heat exchanger chamber 17, and the second air supply port 3, The second air return port 21 and the second blower 22 used to exhaust the air in the second heat exc...

specific Embodiment 2

[0018] combined with Figure 5 And attached Figure 6 , a grain cooling dryer, which includes a casing 1 and a power supply, the casing 1 is provided with a controller 20; the casing 1 is also provided with a first heat exchanger chamber 19, a second heat exchanger chamber 17 and Two working units, the two working units are respectively the first working unit and the second working unit, and the first working unit includes a first compressor 5, a first heat exchanger 8, a second heat exchanger 10, a section The flow part 16 and the four-way valve 18; the first heat exchanger 8 is installed in the first heat exchanger chamber 19, and the first air outlet 2, the first air outlet 2 and the first heat exchanger chamber 19 are also installed in the first heat exchanger chamber A return air outlet 9 and the first air blower 7 for exhausting the air in the first heat exchanger chamber 19 to the drying room; the second heat exchanger 10 is installed in the second heat exchanger chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com