Energy-saving circulating air dust collector

A circulating air and energy-saving technology, applied to chemical instruments and methods, cleaning hollow objects, cleaning methods and appliances, etc., can solve problems such as low efficiency, inability to adapt, and unsatisfactory effects, and achieve high dust removal efficiency and high work efficiency , good dust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

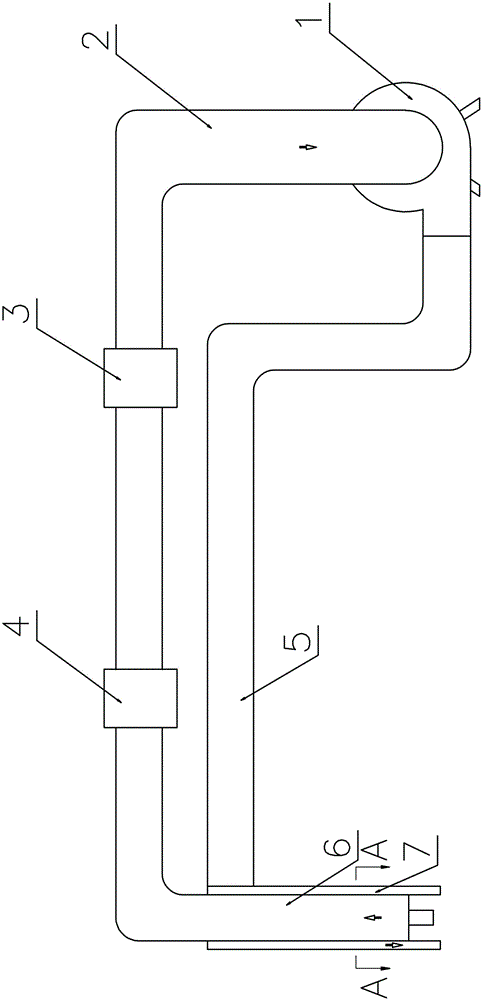

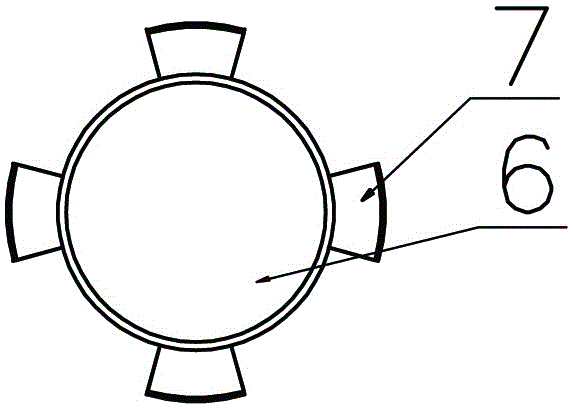

[0014] Example 1: see figure 1 , 2 , the present invention has blower fan 1, especially: a blower suction device is connected with blower fan 1, and this device has a middle suction pipe 6, and four blowpipes are arranged around suction pipe 6, and these four blowpipes 7 are compared with each other. The central air suction pipe 6 grows 150mm; the air suction pipe 6 in the blowing suction device connects the air inlet of the blower fan 1 through the main pipe 2, and each blowing pipe 7 in the blowing suction device is connected to the outlet of the blower fan 1 through the auxiliary pipe 5. The tuyere, and in the main pipeline of the suction pipe 6, a cyclone dust collector 3 and a gravity dust collector 4 are installed, and only one of them can also be installed according to production needs.

example 2

[0015] Example 2: Another embodiment of the present invention is to change based on the structure of Example 1, specifically to change the middle suction pipe in the blowing and suction device of Example 1 into a blowing pipe to connect the air outlet of the blower fan through an auxiliary pipeline, and change the example 1 Change the blowing pipe around the blowing and suction device to the suction pipe, connect the air inlet of the fan through the main pipe, and install a dust removal device in the main air pipe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com