Self-cleaning method of surface cleaning machine with cleaning seat

A surface cleaning and self-cleaning technology, applied in cleaning machinery, robot cleaning machines, cleaning devices, etc., can solve the problems of poor self-cleaning effect of surface cleaning machines, and achieve the effect of reducing the residue of dirty liquid and facilitating drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

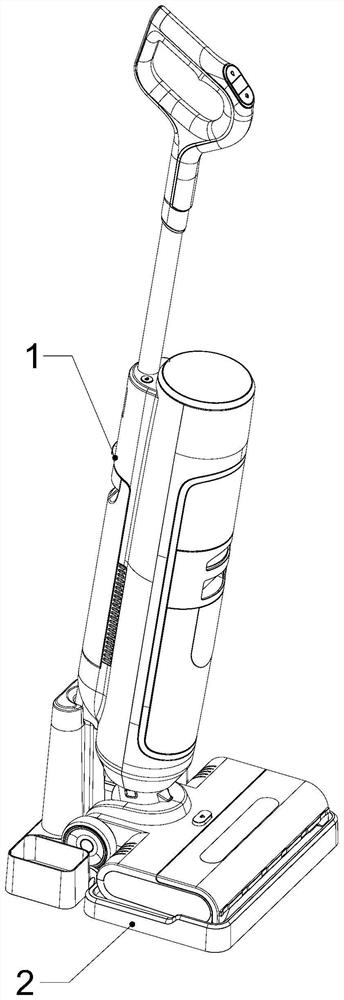

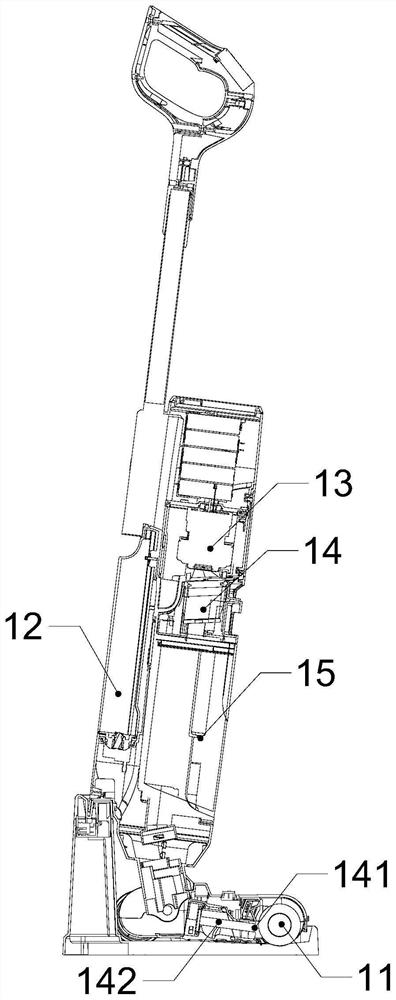

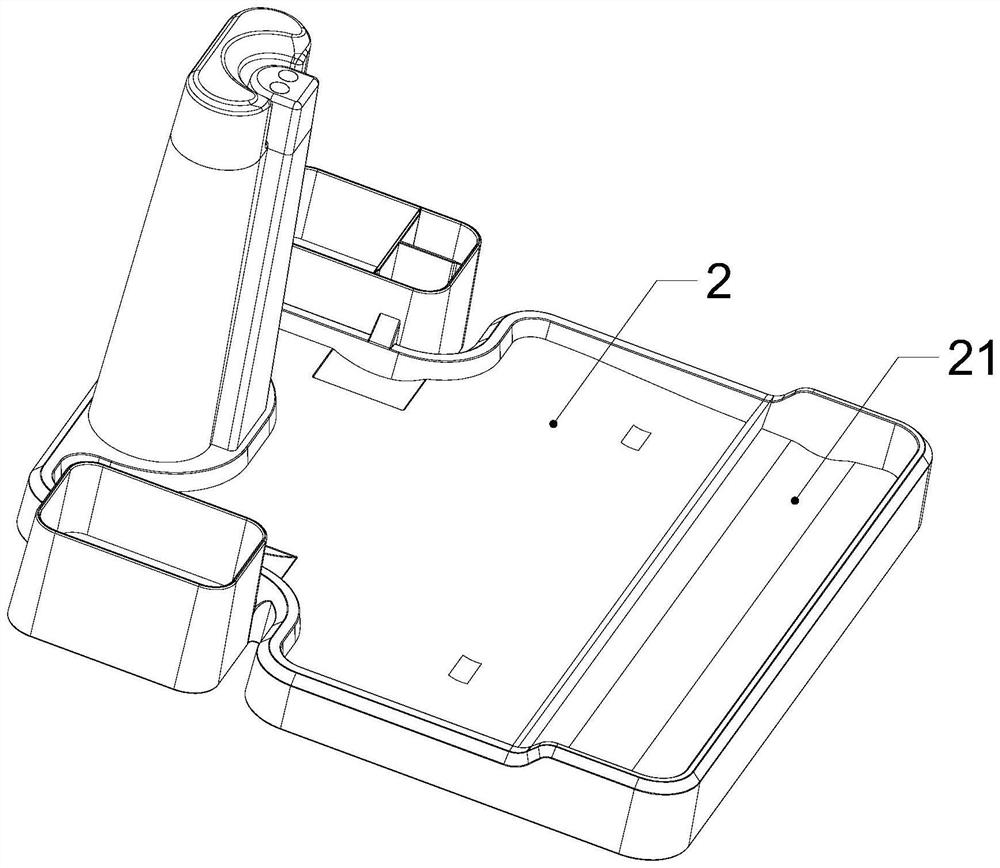

[0042] Embodiment one: if Figure 1 to Figure 3 As shown, the surface cleaning machine 1 of the present invention includes a cleaning roller 11 driven by a rolling brush motor, a water supply device 12 and a dirt suction device 14 driven by a dirt suction motor 13 . Wherein the dirt suction device 14 includes a dirt suction port 141 , a dirt bucket 15 and a dirt suction pipeline 142 connecting the dirt suction mouth 141 and the dirt bucket 15 . The surface cleaning machine 1 also has a matching cleaning seat 2, and the cleaning seat 2 is provided with a cleaning tank 21. When performing self-cleaning, the surface cleaning machine 1 is placed on the cleaning seat 2, so that the cleaning tank 21 on the cleaning seat 2 The cleaning roller 11 can be accommodated.

[0043] Such as Figure 4 As shown, the present invention also provides a self-cleaning method of a surface cleaning machine 1 having a cleaning seat 2, comprising the following steps:

[0044] The surface cleaning ma...

Embodiment 2

[0060] Embodiment two: if Figure 5 As shown, compared with the first embodiment, the self-cleaning method of the surface cleaning machine 1 in this embodiment also includes a step S4-spin-drying stage arranged after the step S3-staining suction stage.

[0061] That is, the surface cleaning machine 1 in this embodiment can obtain a self-cleaning signal and start a self-cleaning mode, wherein the self-cleaning mode includes the following sub-steps:

[0062] Step S1-surface cleaning stage: the surface cleaning machine 1 turns on the water supply device 12, and the cleaning liquid in the water supply device 12 can flow through the water supply channel at the first flow value Q1 and spray liquid into the cleaning roller 11 or the cleaning tank 21 through the water spray port , so that part of the cleaning solution is accumulated in the cleaning tank 21, so that the cleaning solution sprayed by the water supply device 12 can at least wet and clean the bristles on the surface of the...

Embodiment 3

[0076] Embodiment three: as Figure 6 As shown, compared with the second embodiment, the self-cleaning method of the surface cleaning machine 1 in this embodiment also includes a judgment whether the cleaning roller 11 is clean or not between the step S3-staining stage and the step S4-spinning stage. clean process.

[0077] That is, the surface cleaning machine 1 can obtain the self-cleaning signal and start the self-cleaning mode, wherein the self-cleaning mode includes the following sub-steps:

[0078] Step S1-surface cleaning stage: the surface cleaning machine 1 turns on the water supply device 12, and the cleaning liquid in the water supply device 12 can flow through the water supply channel with the first flow value Q1 and spray into the cleaning roller 11 or the cleaning tank 21 through the water nozzle, So that part of the cleaning liquid is accumulated in the cleaning tank 21, so that the cleaning liquid sprayed out by the water supply device 12 can at least wet and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com