Cooling machining die capable of maintaining pressure and used for top-layer foil of elastic foil gas bearing

A gas bearing and elastic foil technology, applied in the field of pressure-maintaining cold working molds, can solve the problems of difficult processing methods, inability to accurately meet the processing requirements, and large springback, and achieve low cost, simple structure, and energy saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in detail below in conjunction with the accompanying drawings.

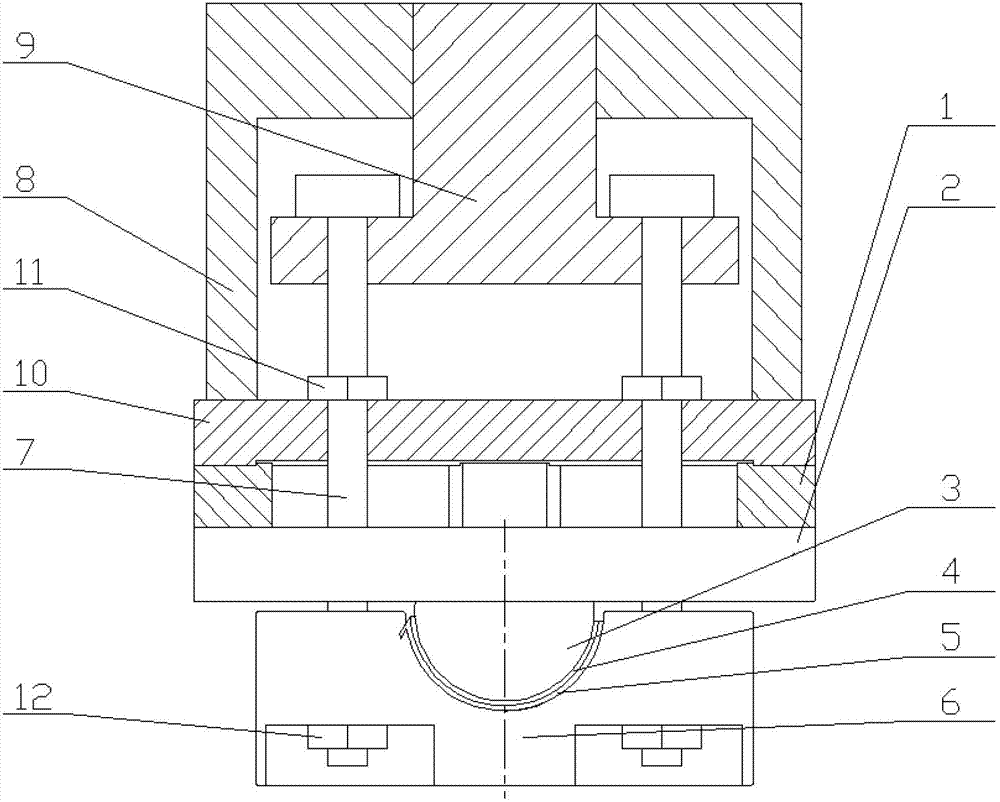

[0010] Referring to the accompanying drawings, a pressure-holding cold working mold for the top foil of an elastic foil gas bearing includes a disc-shaped upper mold 2, and the upper mold 2 is equipped with a positioning ring 1, and the positioning ring 1 and the upper mold 2 are used Bolt connection, the positioning ring 1 and the groove of the pressure plate 10 of the hydraulic tension machine 8 are positioned together, the lower surface of the upper mold 2 is provided with a semi-cylinder 3, and the lower mold 6 is provided with a concave surface that matches the semi-cylindrical 3, and there is a groove on the concave surface. The groove is used to install the top foil 5, the pull rod 7 passes through the pull rod 9, the pressure plate 10, the upper die 2 and the lower die 6 of the hydraulic tension machine 8, the pull rod 7 is located under the lower die 6 and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com