A constant velocity universal joint bell shell scraping tool

A technology of constant velocity universal joints and bell-shaped shells, which is applied in the field of scraping tooling for the bell-shaped shells of constant velocity universal joints. Achieve the effects of avoiding accumulated errors, improving processing efficiency, and improving production accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

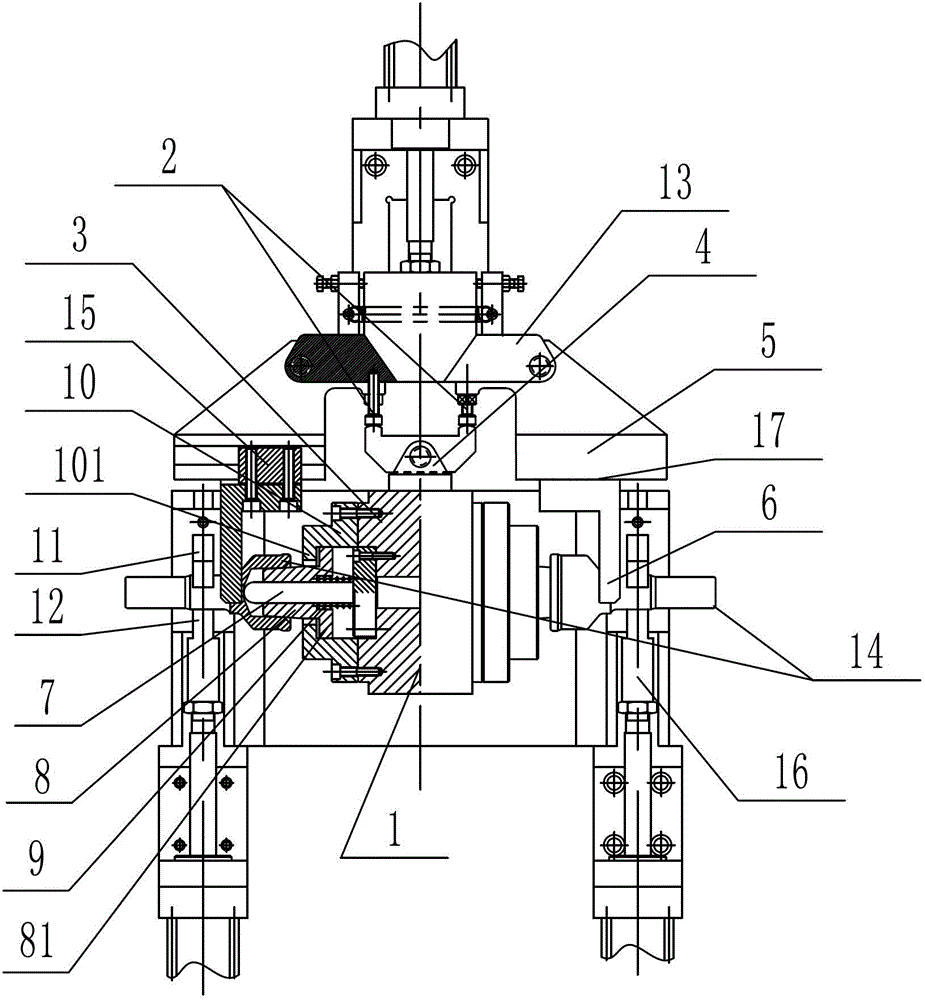

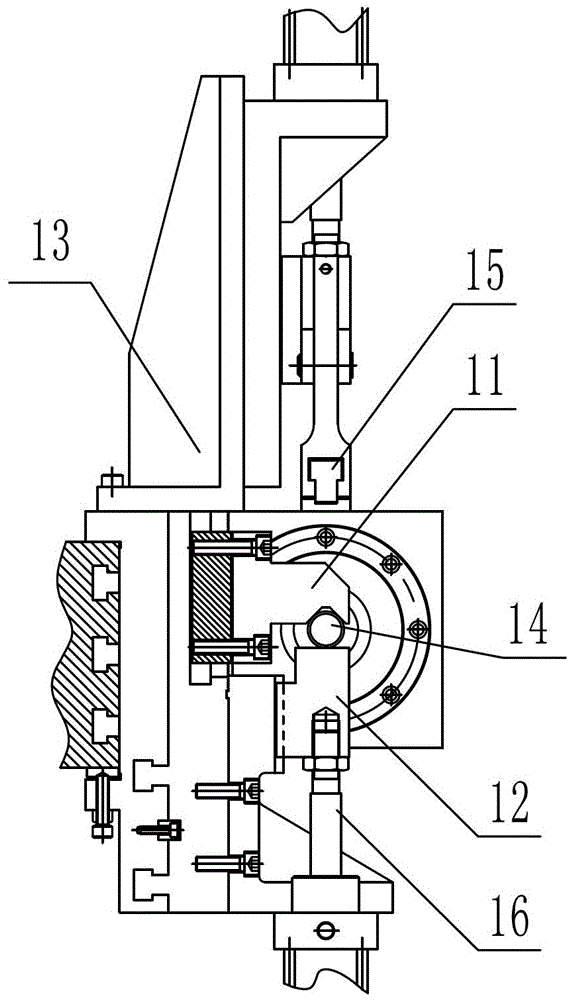

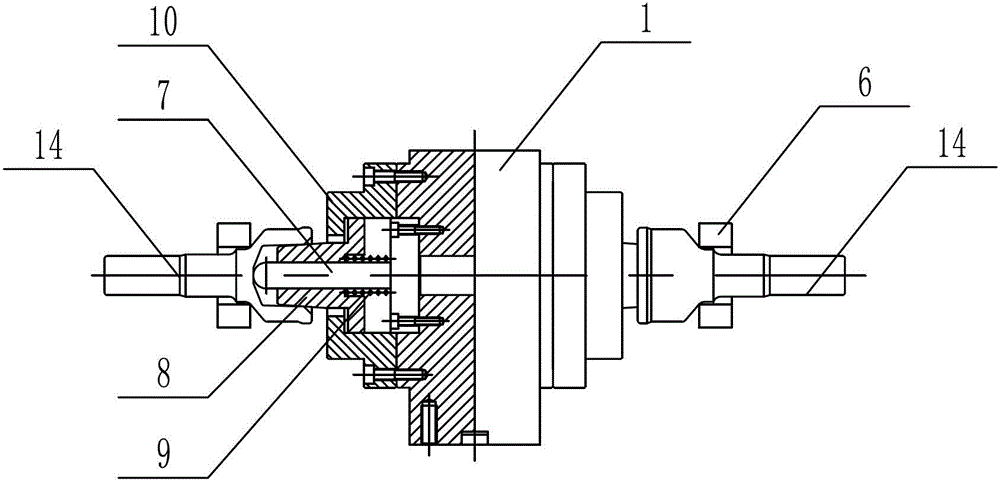

[0043] Such as Figures 1 to 8As shown, a constant velocity universal joint bell-shaped shell scraping tool includes a bracket 13 and a positioning device arranged on the bracket 13 for positioning the workpiece 14. The positioning device includes a reference positioning device for benchmarking the workpiece 14. The reference positioning device includes a workpiece base plate 1 and a lining structure provided on the workpiece base plate 1 that can extend into and line the inner wall of the workpiece 14 . The workpiece 14 is a bell-shaped housing cup of a constant velocity joint. The lining structure includes a workpiece positioning rod 7 arranged on the workpiece seat plate 1 and a workpiece cover 8 arranged on the workpiece seat plate 1. The workpiece positioning rod 7 extends into the workpiece 14 and is against the inner bottom wall of the workpiece 14. The workpiece The cover 8 extends into the workpiece 14 and is lined on the inner side wall of the workpiece 14. The work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com