A no-surplus mechanical finishing process for removing tool marks on the blade body profile

An airfoil profile and finishing technology, which is applied to surface polishing machine tools, machine tools suitable for grinding workpiece edges, manufacturing tools, etc. The problem of uncontrollable quantity, etc., can achieve the effect of avoiding the positional deviation, improving the processing quality, and evenly distributing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

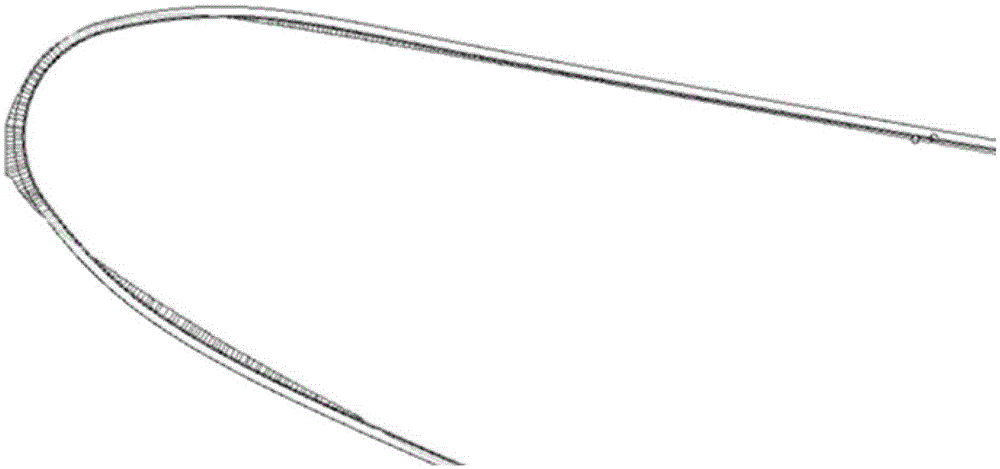

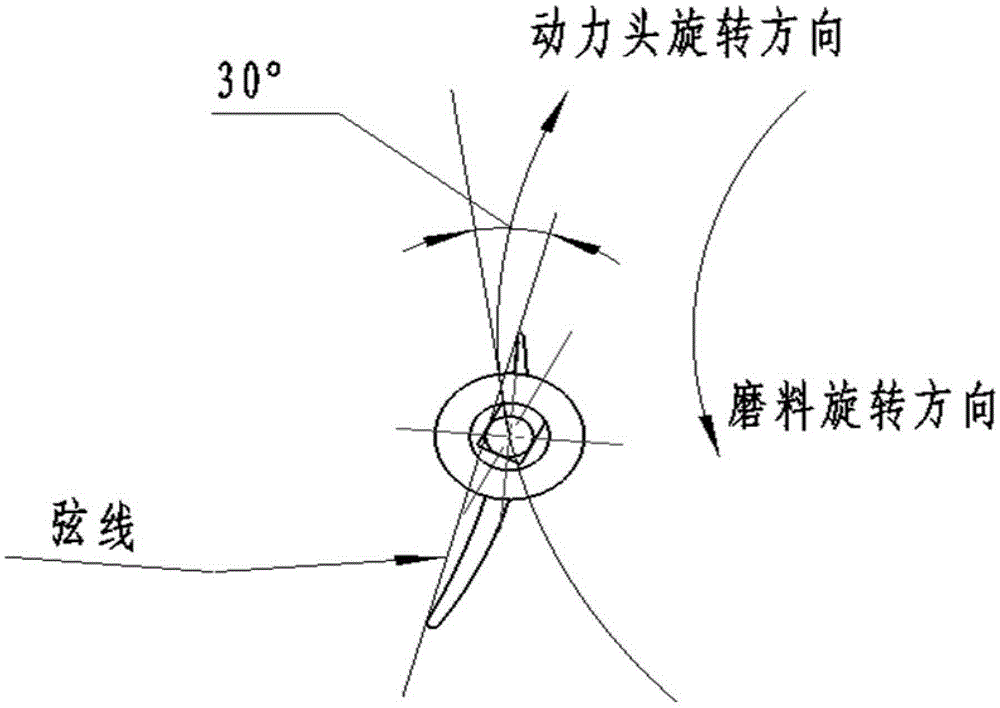

[0024] This embodiment provides a no-residue mechanical finishing process for removing knife marks on the blade body profile, which is characterized in that: the mechanical finish no-residue process for removing tool marks on the blade body profile, in order to realize the The amount of contour removal is controllable, the radius R of the front and rear edges maintains the roundness state after CNC milling, and the finishing process, equipment, fixtures and processing parameters are optimized to achieve the finishing target;

[0025] Finishing process:

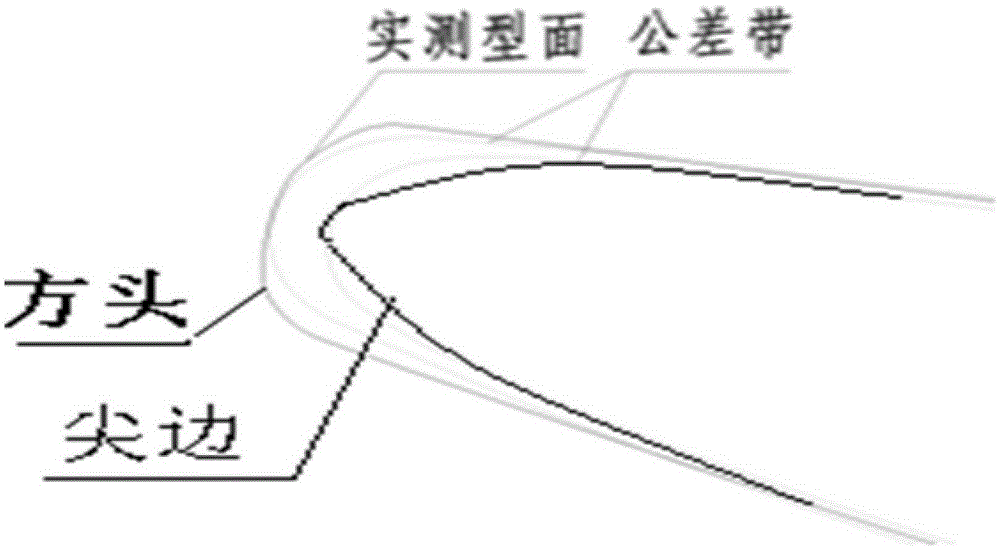

[0026] In order to solve the problem of edge trimming caused by different removal speeds at the radius R of the airfoil profile and the leading and trailing edges during skin finishing, the airfoil profile is divided into rough and fine finishing processes, which are used to remove the profile and the leading and trailing edges respectively. The tool mark at the radius R, and meet the roughness requirements;

[0027] Equipmen...

Embodiment 2

[0034] This embodiment provides a no-residue mechanical finishing process for removing knife marks on the blade body profile, which is characterized in that: the mechanical finish no-residue process for removing tool marks on the blade body profile, in order to realize the The amount of contour removal is controllable, the radius R of the front and rear edges maintains the roundness state after CNC milling, and the finishing process, equipment, fixtures and processing parameters are optimized to achieve the finishing target;

[0035] Finishing process:

[0036] In order to solve the problem of edge trimming caused by different removal speeds at the radius R of the airfoil profile and the leading and trailing edges during skin finishing, the airfoil profile is divided into rough and fine finishing processes, which are used to remove the profile and the leading and trailing edges respectively. The tool mark at the radius R, and meet the roughness requirements;

[0037] Equipmen...

Embodiment 3

[0044] This embodiment provides a no-residue mechanical finishing process for removing knife marks on the blade body profile, which is characterized in that: the mechanical finish no-residue process for removing tool marks on the blade body profile, in order to realize the The amount of contour removal is controllable, the radius R of the front and rear edges maintains the roundness state after CNC milling, and the finishing process, equipment, fixtures and processing parameters are optimized to achieve the finishing target;

[0045] Finishing process:

[0046] In order to solve the problem of edge trimming caused by different removal speeds at the radius R of the airfoil profile and the leading and trailing edges during skin finishing, the airfoil profile is divided into rough and fine finishing processes, which are used to remove the profile and the leading and trailing edges respectively. The tool mark at the radius R, and meet the roughness requirements;

[0047] Equipmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com