Preheating tank for heating sludge by steam

A preheating tank and steam technology, applied in the direction of sludge treatment through temperature control, can solve the problems of uneven heat exchange between sludge and steam, low heat exchange efficiency of steam, and insufficient heat utilization, so as to reduce sludge treatment Disposal costs, reduced energy consumption, and the effect of reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The principles and features of the present invention will be described below with reference to the accompanying drawings. The examples are only used to explain the present invention, but not to limit the scope of the present invention.

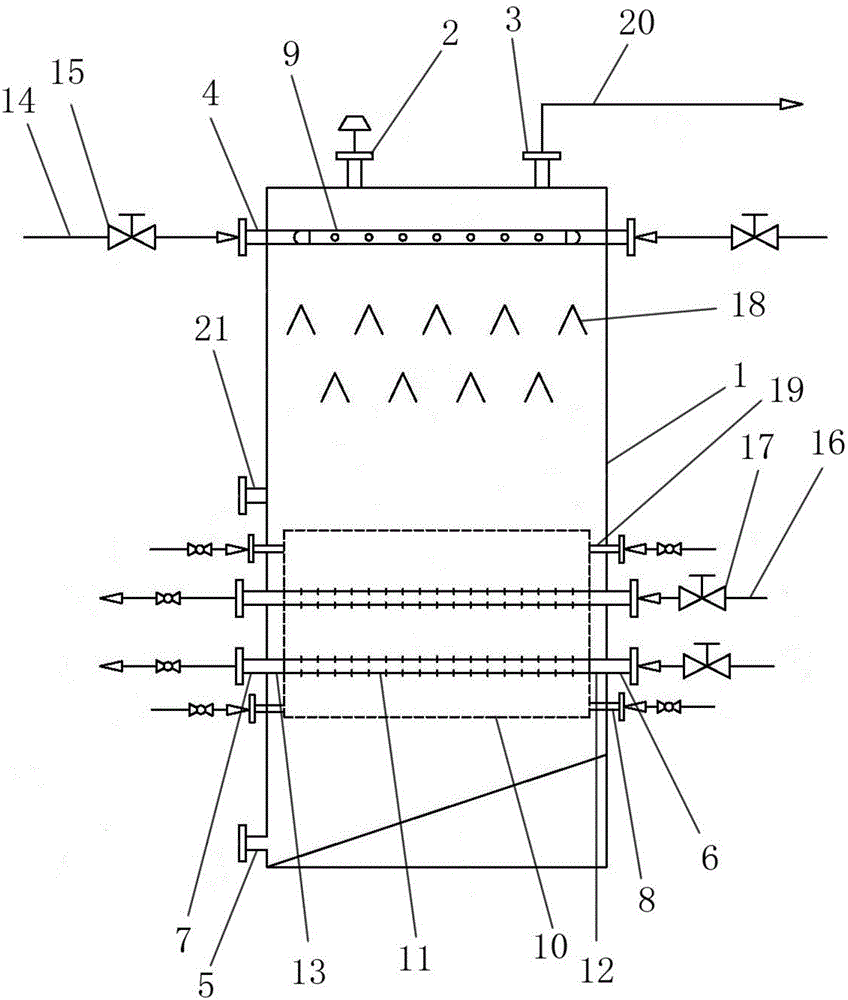

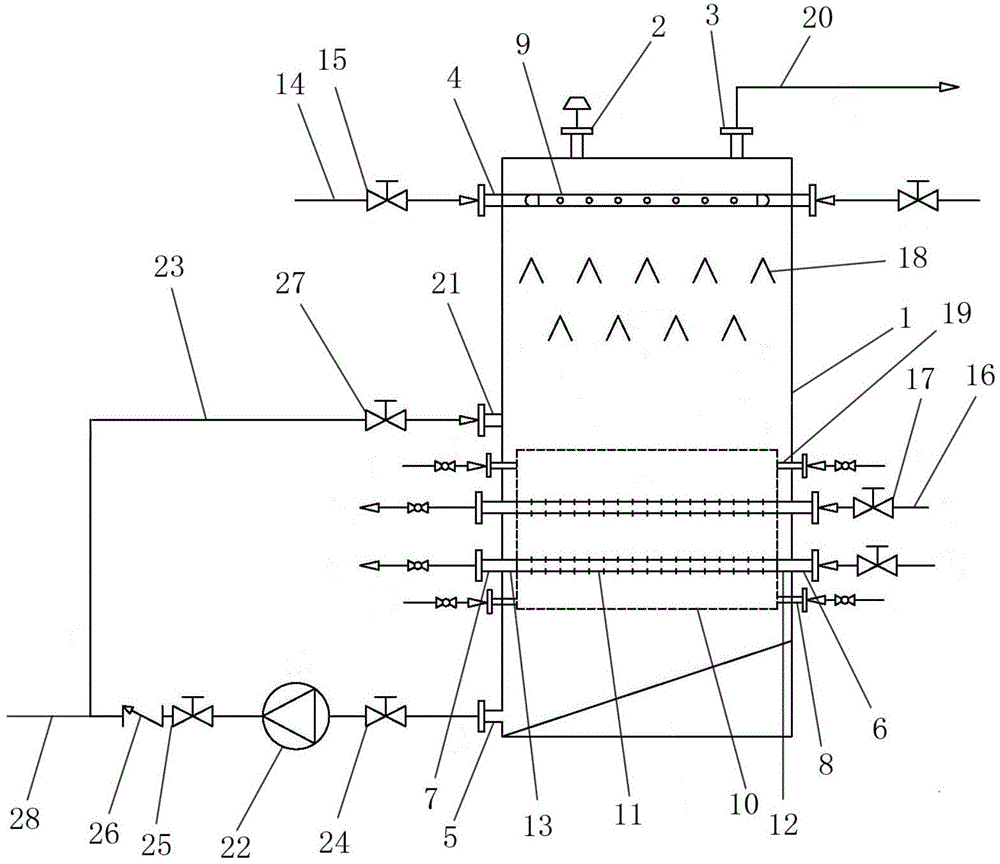

[0026] figure 1 It is a schematic structural diagram of the first embodiment of a preheating tank for heating sludge by using steam according to the present invention.

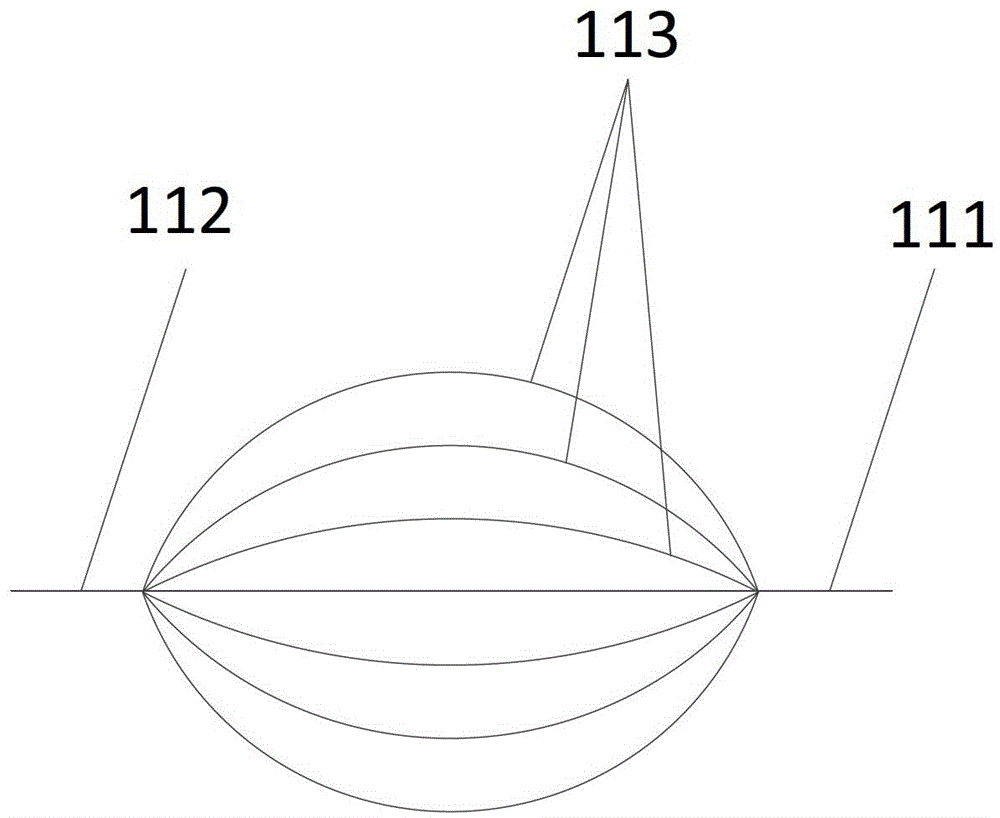

[0027] As shown in the figure, the preheating tank for heating sludge by steam includes a tank body 1, a breathing valve 2 and an exhaust end 3 are provided on the top of the tank body 1, and a piercing valve is provided on the outer side of the top side wall of the tank body 1. The mud inlet end 4 passing through the side wall of the tank body, the outer side of the bottom side wall of the tank body 1 is provided with a mud outlet end 5 passing through the side wall of the tank body, and the outer side of the side wall of the tank body 1 is also provided with a The st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com