Adjusting screw for adjusting valve clearance of motorcycle

A valve clearance and adjusting screw technology, which is applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of inability to guarantee one-time adjustment, long time-consuming, cumbersome operation, etc., and achieve ingenious design, easy implementation, and proficiency less demanding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

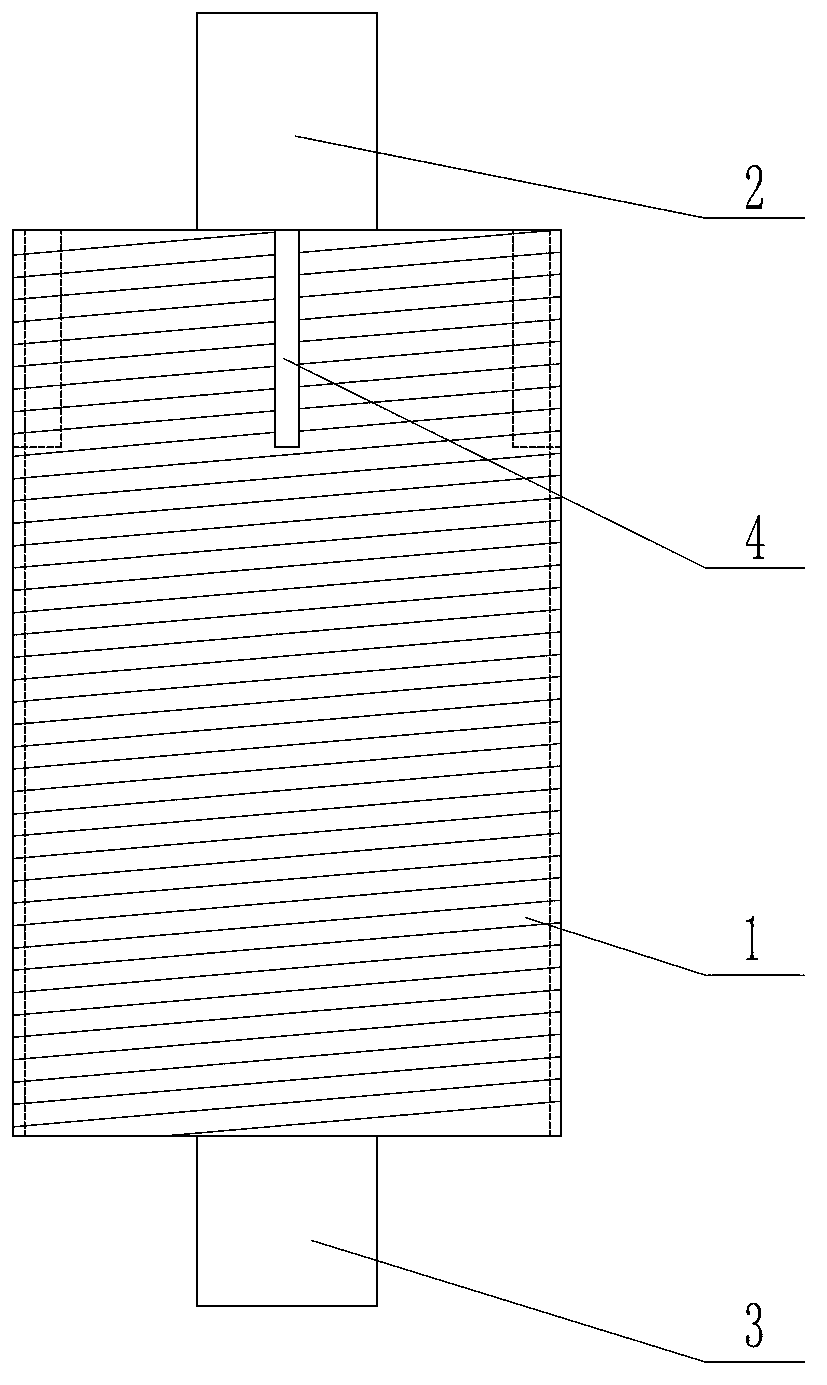

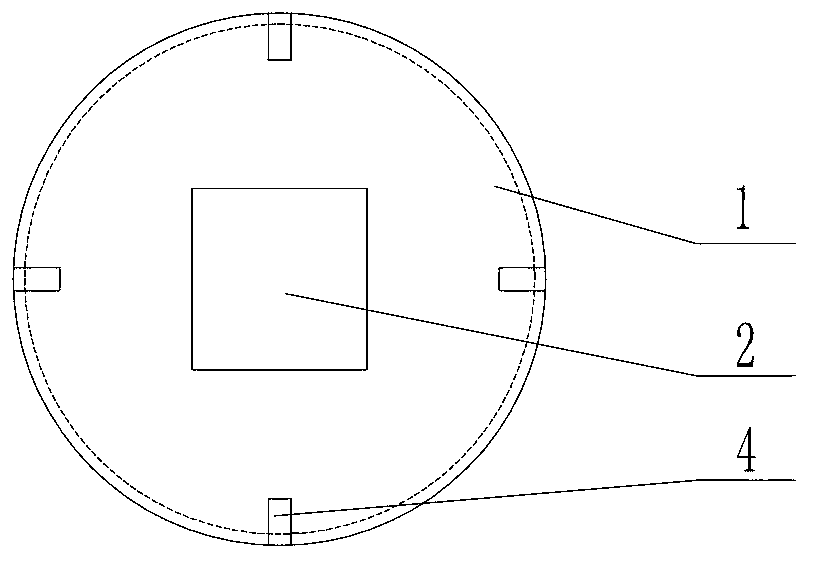

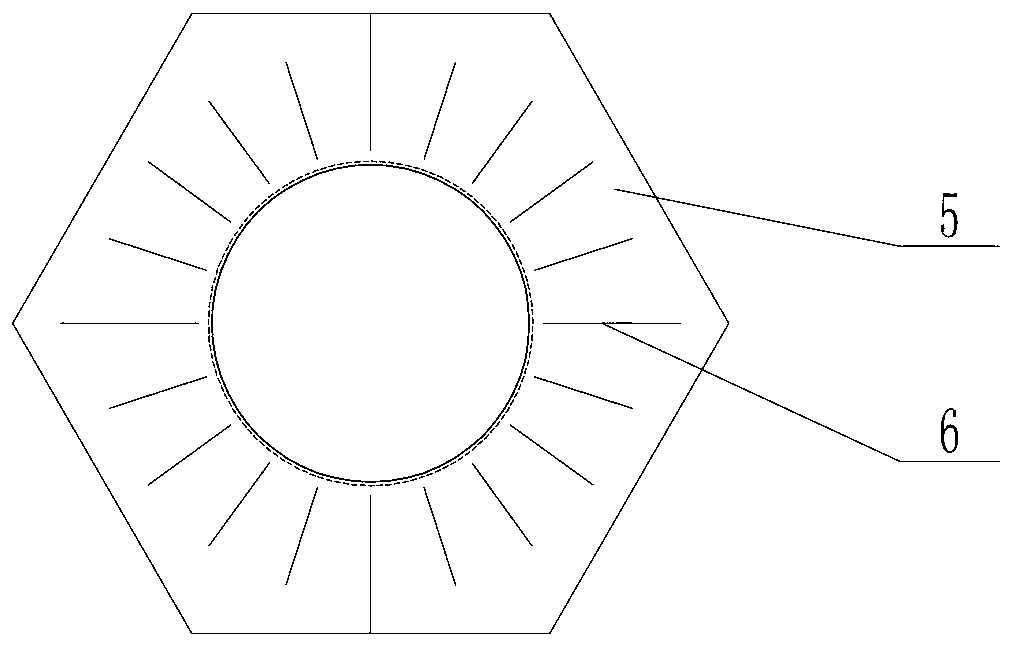

[0016] like figure 1 , figure 2 As shown, the present invention is composed of a large cylinder 1, an adjustment column 2 and a top column 3. The adjustment column 2 is a square column, and the adjustment column 2 is located at the central position of the top surface of the large cylinder 1, and is arranged at the center of the bottom surface of the large cylinder 1. The top column 3, the large cylinder 1, the adjustment column 2 and the top column 3 are integrally structured, and the axis lines of the three are on a straight line. Threads are processed on the circumferential surface of the large cylinder 1, and the pitch of the threads is preferably 1mm. The circumferential surface of the upper end of the large cylinder 1 is provided with four grooves 4 evenly distributed on the circumference, and each groove 4 extends axially along the large cylinder 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com