Annular reciprocating type piston engine and even permutation annular reciprocating type piston engine

A piston engine, reciprocating technology, applied in the direction of machines/engines, mechanical equipment, etc., can solve the problems of large friction loss of piston rings, reduce the life of piston rings and cylinders, reduce the service life of engines, etc., and achieve high output power and output torque. , Improve the mechanical efficiency, reduce the effect of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

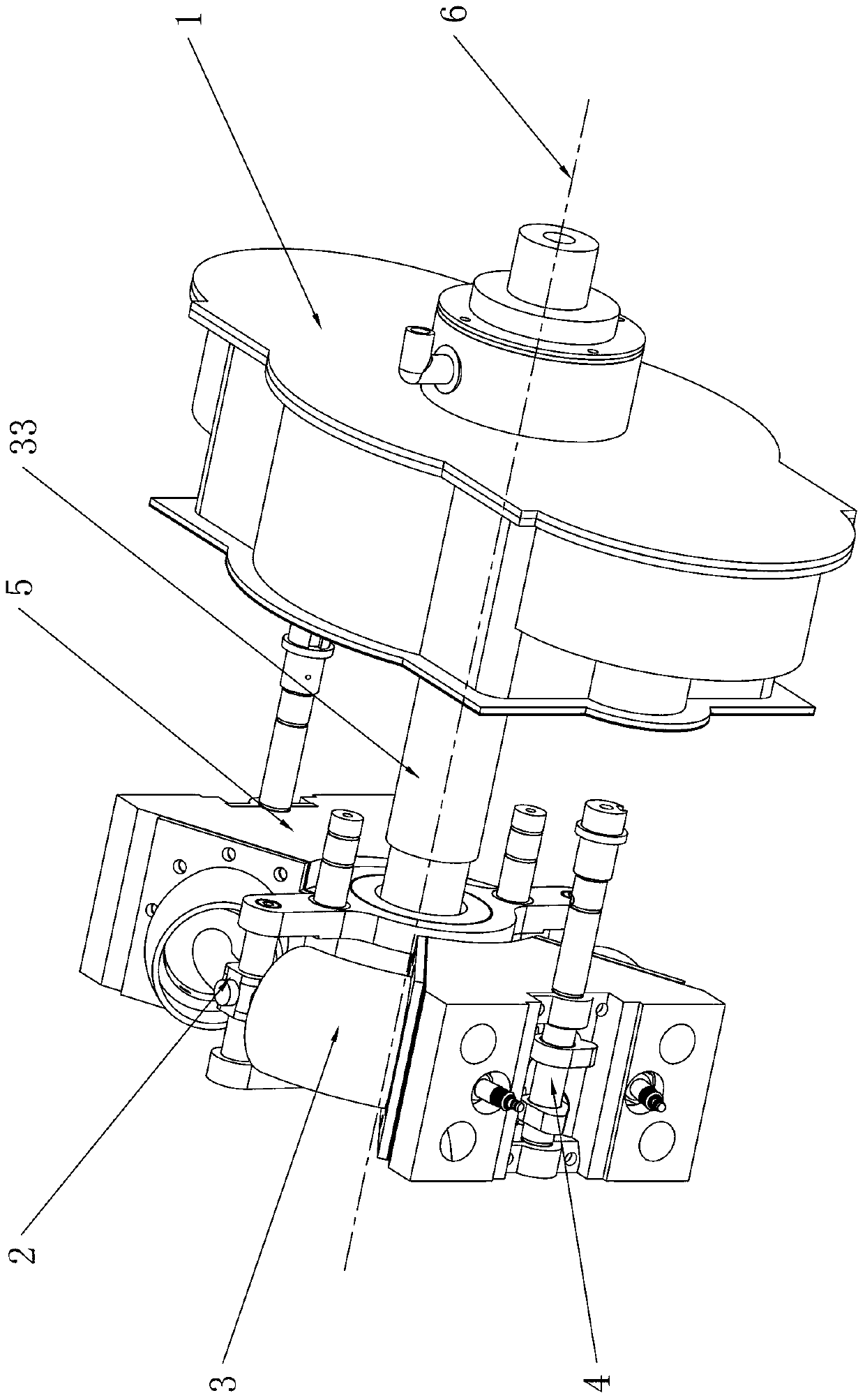

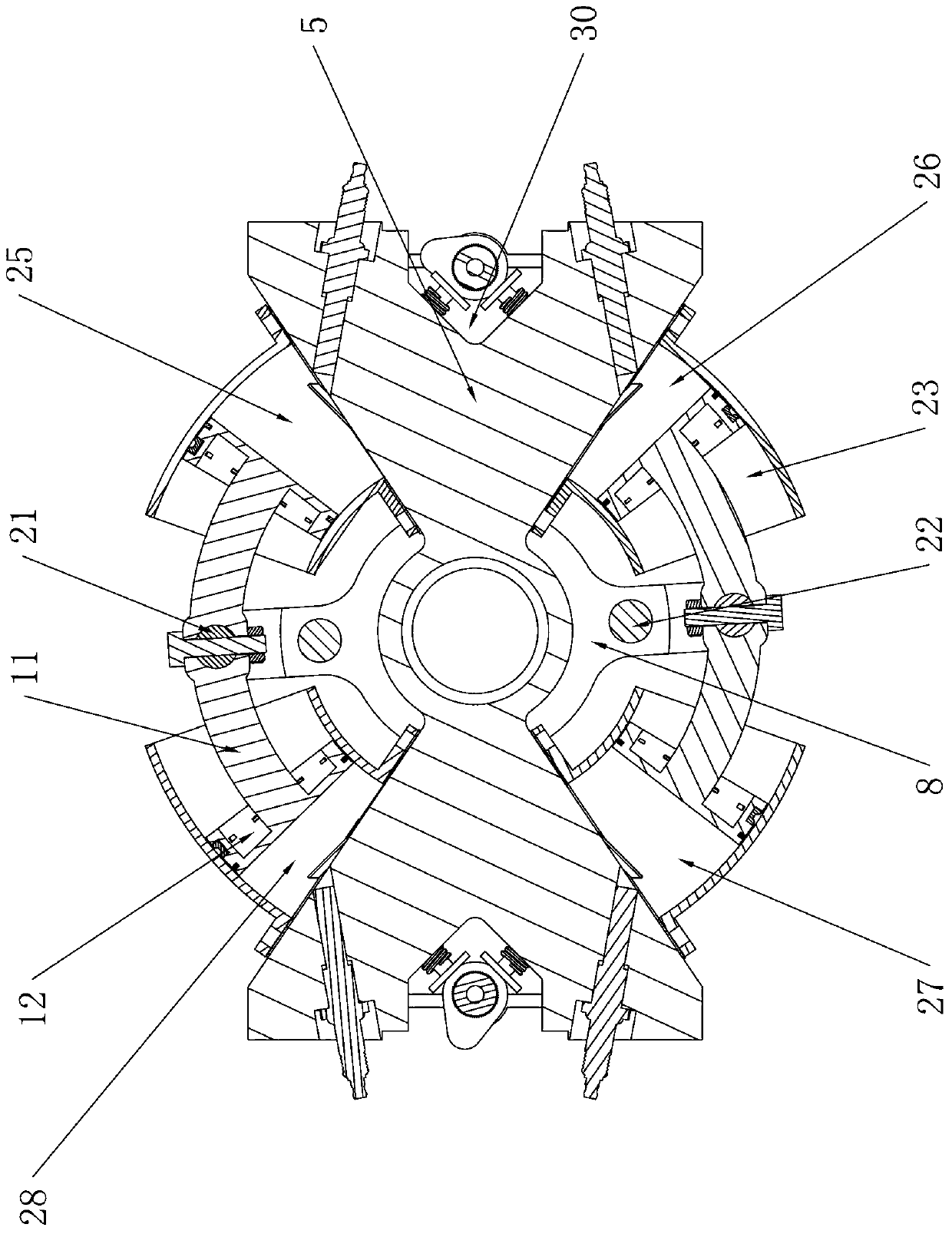

[0035] Implementation mode one: if figure 1 and 2 As shown, the annular reciprocating piston engine of the present invention includes an output main shaft 33, a transmission mechanism 1 and a main body of the engine, on which an intake valve 31, an exhaust valve 32, a piston assembly 2, a cylinder assembly 3 and a cam assembly are installed 4. Wherein, the above-mentioned engine body includes a structural main body 5 with fan-shaped bodies on both sides, the above-mentioned cylinder assembly 3 is installed on the structural main body 5 in a ring shape, the above-mentioned piston assembly 2 is installed in the cylinder assembly 3 and moves reciprocatingly in a ring shape, and the above-mentioned piston assembly 2 and the central axis of the cylinder assembly 3 are coaxial with the axis 6 of the output spindle 33 .

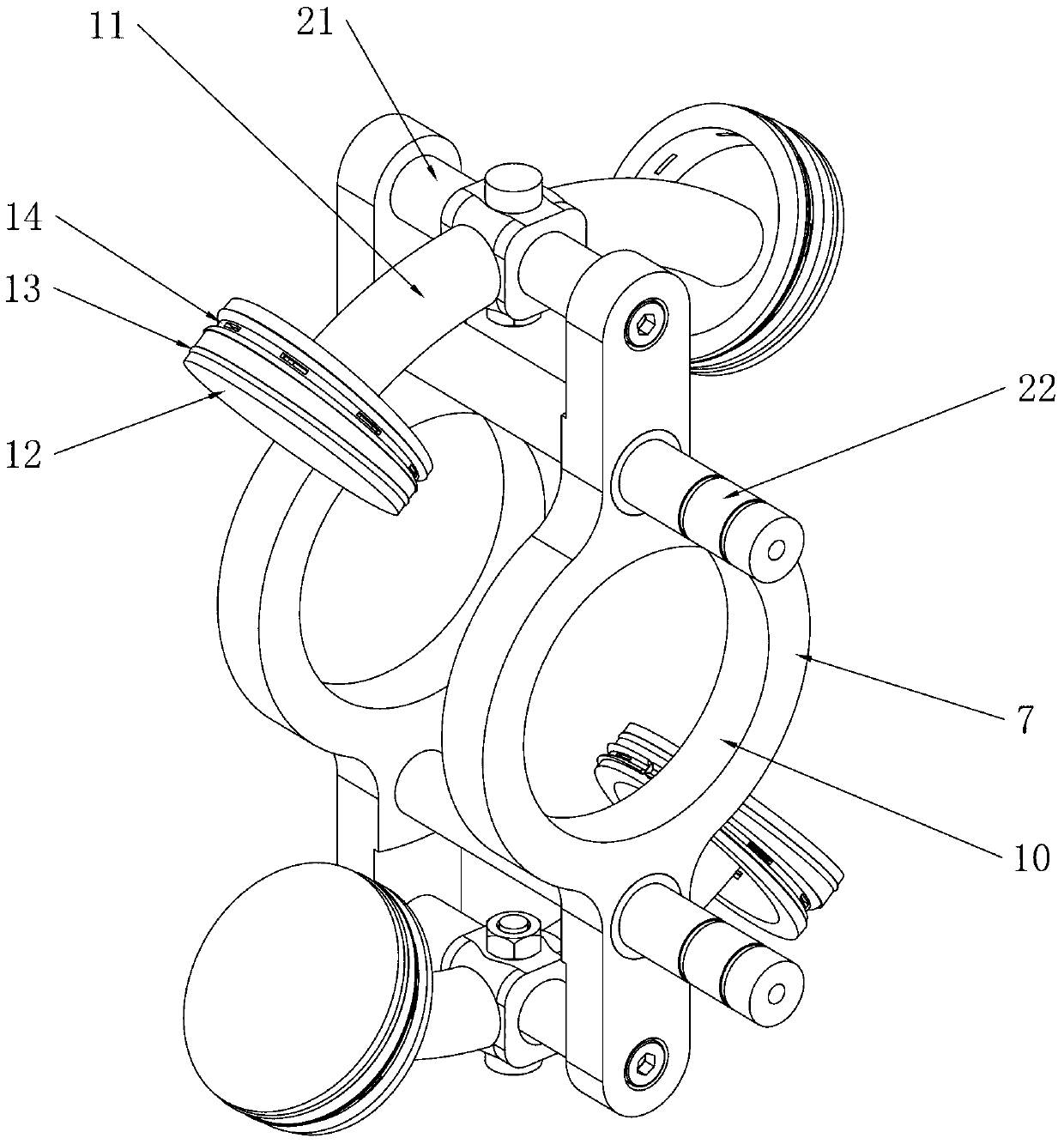

[0036] Such as image 3 , 5 , 8, 9 and 11, the above-mentioned piston assembly 2 includes a piston flange 7 arranged on the structural body 5 and rotatably match...

Embodiment approach 2

[0044] Implementation mode two: if Figure 4 As shown, this embodiment is basically the same as Embodiment 1, the difference is that the above-mentioned piston assembly 2 also includes a piston transmission rod 22 connected to the piston flange 7, and the piston transmission rod 22 is connected with the above-mentioned transmission mechanism 1, and the above-mentioned transmission Mechanism 1 drives piston assembly 2 to perform circular reciprocating motion. The piston transmission rod 22 can be located in the piston fixed rod 21 to reduce the size of the transmission mechanism 1, and the piston fixed rod 21 can also be used as the piston transmission rod 22. The piston head 12 is provided with two air seal rings 13 and one oil seal ring 14 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com