Dedicated piston assembly for reciprocating piston type gas compressor

A technology of gas compressors and reciprocating pistons, applied in variable capacity pump components, liquid variable capacity machines, pump components, etc., can solve problems such as not being able to significantly improve machine operating efficiency, failure, increased frictional power consumption, and heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

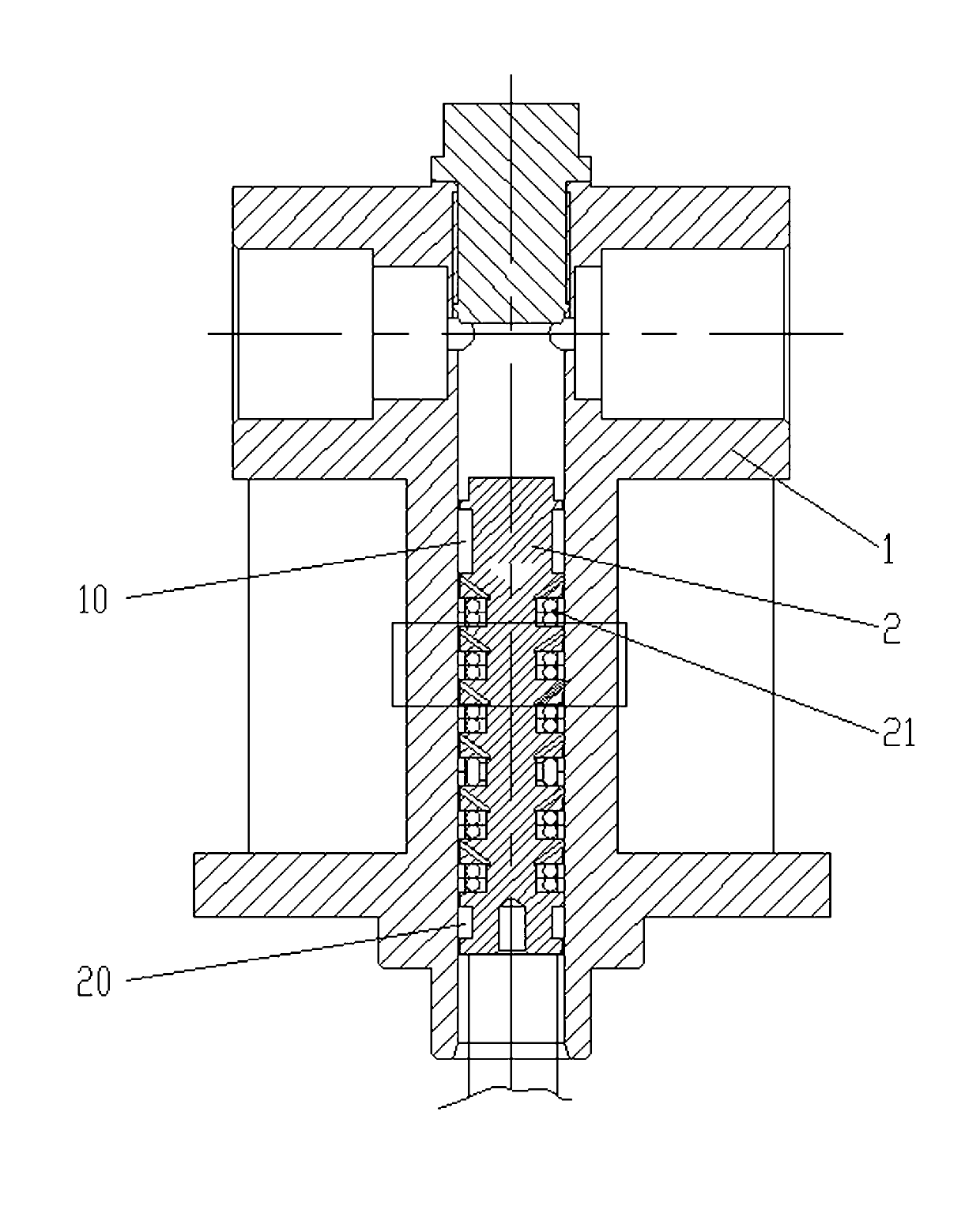

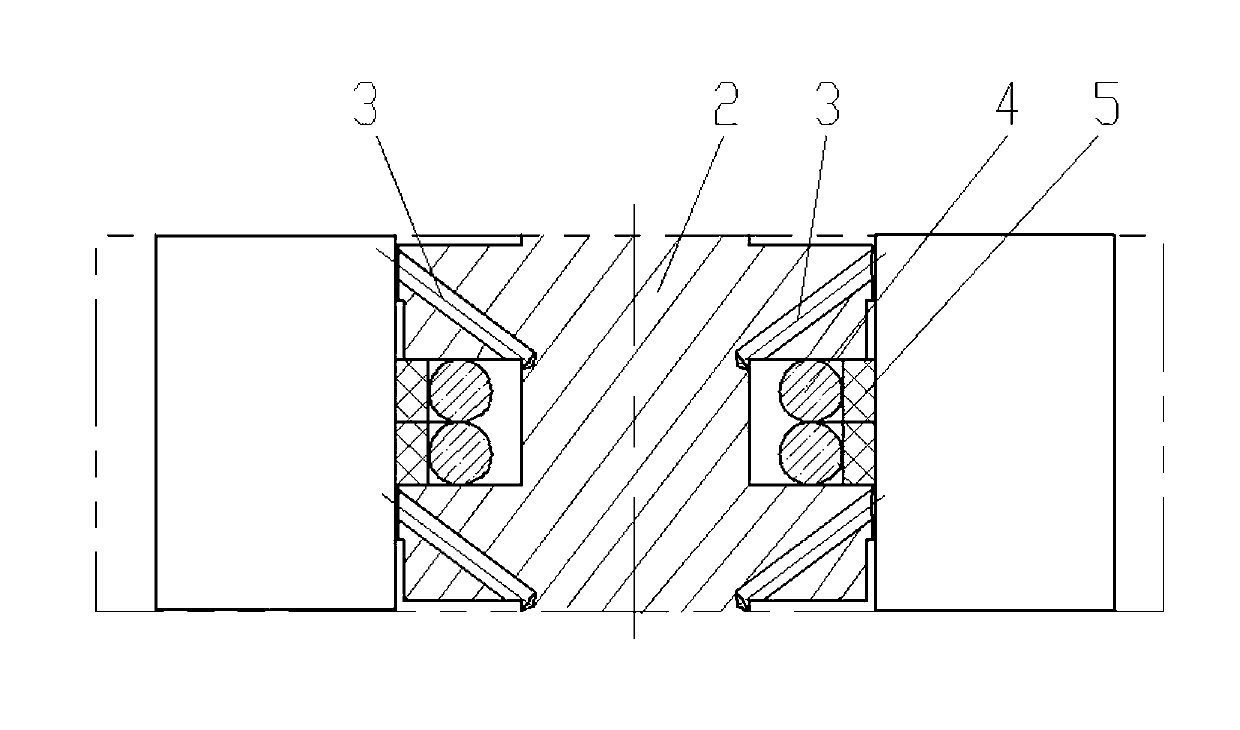

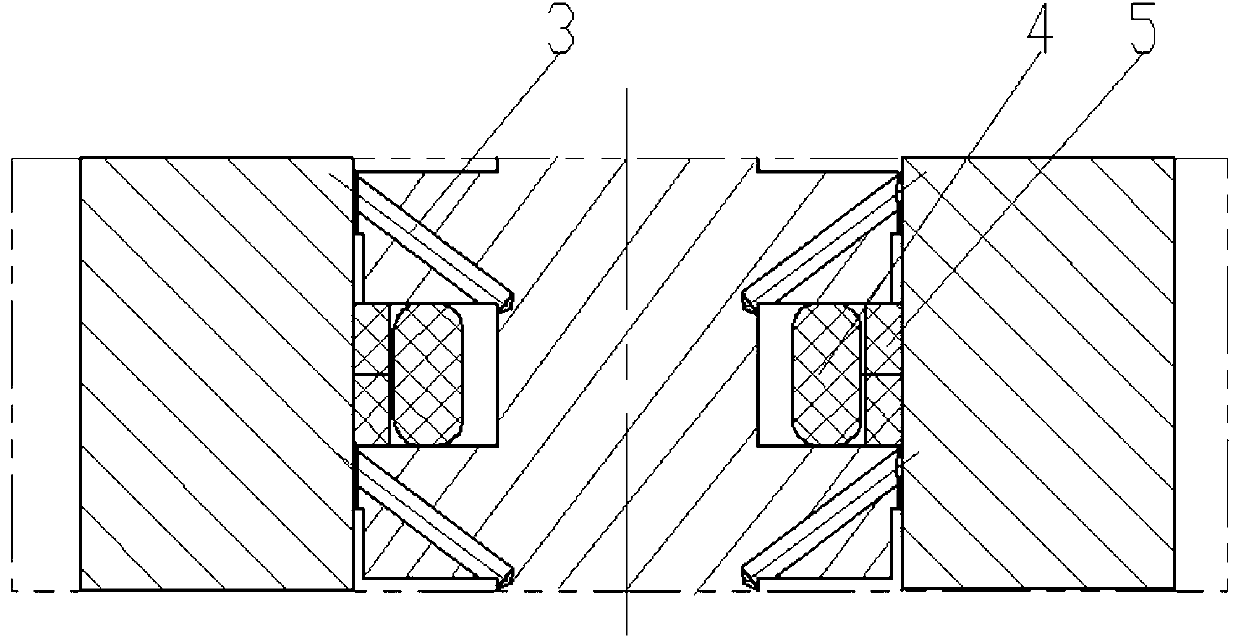

[0017] Such as figure 1 , figure 2 , image 3 , Figure 4 It can be seen that the piston assembly dedicated to the reciprocating piston gas compressor of the present invention includes a cylinder 1 and a matching piston 2, and the two ends of the piston 2 are respectively equipped with an upper guide ring 10 and a lower guide ring 20, which is characterized in that: The piston 2 is provided with a plurality of annular grooves 21, and a piston ring 5 sealingly connected with the cylinder 1 is arranged in the annular grooves 21, and at least one sealing ring 4 is arranged inside the piston ring 5 in each annular groove 21.

[0018] The upper guide ring 10 and the lower guide ring 20 keep the piston 2 and the cylinder 1 in a coaxial state all the time. Both the piston 2 and the cylinder 1 are made of metal, and they can move relative to each other and are in sealing contact through a plurality of piston rings 5 . The piston ring 5 is made of non-metallic material, which can...

Embodiment 2

[0025] Such as figure 1 , 2 , 3, 4 It can be seen that the difference between this embodiment and Embodiment 1 is that, in the case of a larger bore of the cylinder 1, the sealing ring 4 is one, and its cross-sectional shape and inner diameter are the same as those of the piston ring 5 and the annular groove 21. Matching, its sealing performance is better and easy to assemble. In this embodiment, the cross-sectional shape of the sealing ring 4 is a rectangle with rounded corners.

[0026] The special piston assembly for the reciprocating piston type gas compressor of the present invention can remarkably improve the sealing effect and service life due to the structural change. After testing, it is found that setting 3-4 annular grooves 21 can seal the high-pressure gas, which greatly reduces the manufacturing cost and operating cost of the machine. After 2000h, 15MPa life test, it is proved that its life is far longer than the 1200h stipulated in the compressor standard of o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com