Axial Force Balance Device of Centrifugal Waste Heat Discharge Pump for Nuclear Power

A technology of waste heat discharge pump and balancing device, which is applied to the components of pumping device for elastic fluid, non-variable-capacity pump, pump, etc. Pit allowance, improvement of pressure pulsation, high strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

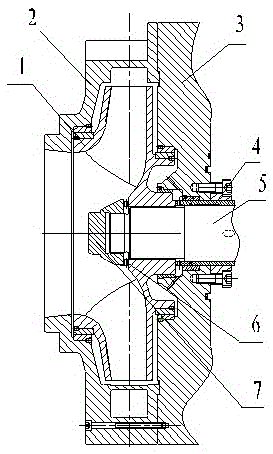

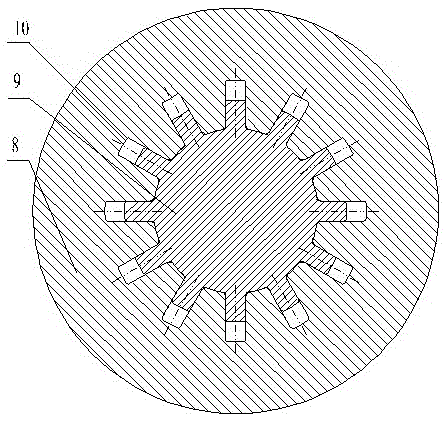

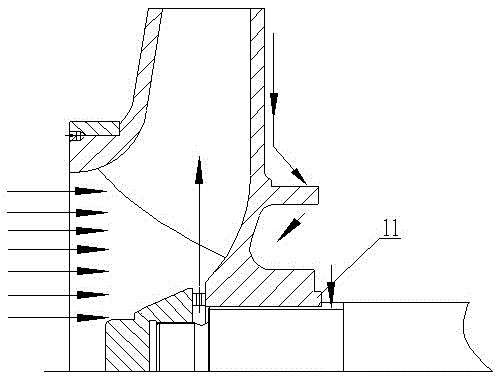

[0017] combine figure 1 , using the radial return hole axial force balance device designed by the present invention, the shaft sleeve 4 is provided with a guide hole, the spline shaft 5 is connected to the impeller 1 through splines to form an axial return channel 10, and the liquid flow passes through the stop washer The radial return hole opened on 6 enters the impeller to form a radial return mode to adjust the axial force. The edge of the hub of impeller 1 is processed into a tooth-shaped groove, which constitutes a gear groove 11. A part of the liquid in the "gear groove" cavity is re-transported to the rear pump chamber between the pump cover 3 and the impeller 1 after being worked by the gear groove. Another part of the liquid enters the return channel 10 formed by the impeller hub 8 and the spline shaft 5 , and finally enters the impeller 1 through the radial return hole on the stop washer 6 .

[0018] combine figure 2 , the spline connection is adopted between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com