Pipeline type welding machine cooler

A cooler and welding machine technology, applied in the direction of heat exchanger types, indirect heat exchangers, fixed conduit components, etc., can solve the problem that the welding machine cannot effectively dissipate heat, and achieve material saving, good thermal conductivity, and good heat dissipation performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

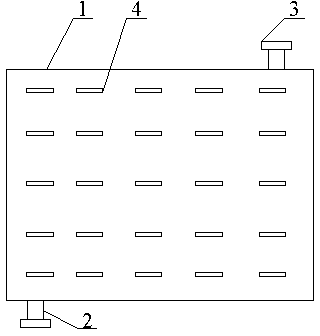

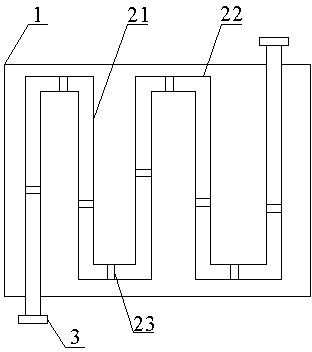

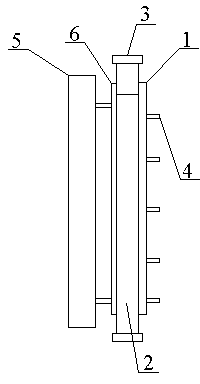

[0029] Such as Figure 1~Figure 3 As shown, the pipe-type welder cooler includes a side plate 1, a serpentine air duct 2 and a fan 3, the serpentine air duct 2 is arranged inside the side plate 1, and the two ends of the serpentine air duct 2 protrude from the side plate 1 respectively. The upper and lower ends of the upper and lower ends of the serpentine air duct 2 are provided with fans 3;

[0030] In use, this embodiment is used to form the side wall of the welding machine housing. A fan 3 sends external cold air into the serpentine air duct 2, and the cold air absorbs the heat emitted by the welding machine in the serpentine air duct 2, and the air that has absorbed the heat is discharged through another fan 3 again. Radiating fins 4 dissipate part of the heat of the air in the serpentine air duct 2 . Through the serpentine air duct 2, the fan 3 and the heat sink 4, this embodiment realizes active heat dissipation and has good heat dissipation performance.

[0031] In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com