A high-efficiency anti-corrosion ozone electrolysis preparation device

A preparation device and anti-corrosion technology, applied in the field of high-efficiency anti-corrosion ozone electrolysis preparation device, can solve problems such as cost surge, waste of energy, deflagration, etc., and achieve the effects of small footprint, large electrolysis efficiency, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

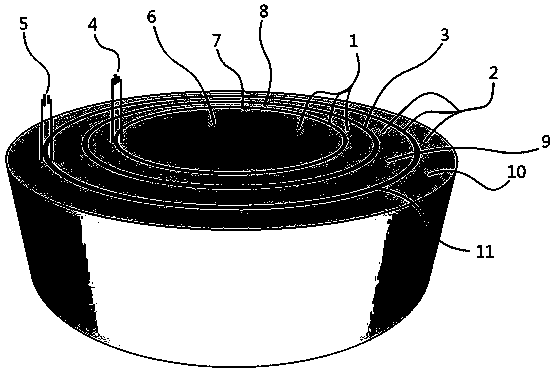

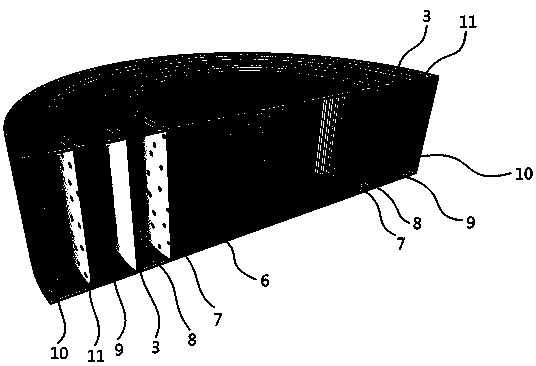

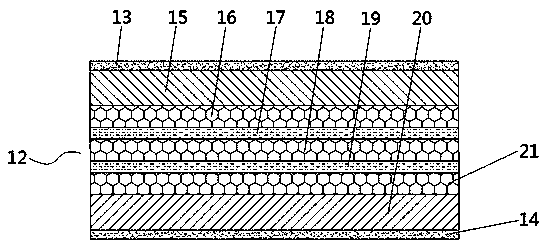

[0043] Attached below Figure 1-4 The technical solutions of the present invention are further described through specific implementation methods.

[0044] A high-efficiency anti-corrosion ozone electrolysis preparation device, including a first electrolytic generator group 1 and a second electrolytic generator group 2, each of which are annular, and the first electrolytic generator group 1 and the second electrolytic generator group are 2 are arranged in concentric circles, the first electrolysis generator group 1 is located at the inner center of the concentric circle, and the second electrolysis generator group 2 surrounds the periphery of the first electrolysis generator group 1 in a ring shape; the first electrolysis generator group 1 A graphene thermally conductive material 3 is arranged between the generator group 1 and the second electrolytic generator group 2, and the graphene thermally conductive material 3 is connected with an external heat exchange device;

[0045]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com