Method and device for measuring thin substrate deformation

A measurement method and thin substrate technology, applied in the direction of measurement devices, optical devices, instruments, etc., to achieve accurate and reliable measurement results and reduce the effect of additional deformation due to gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

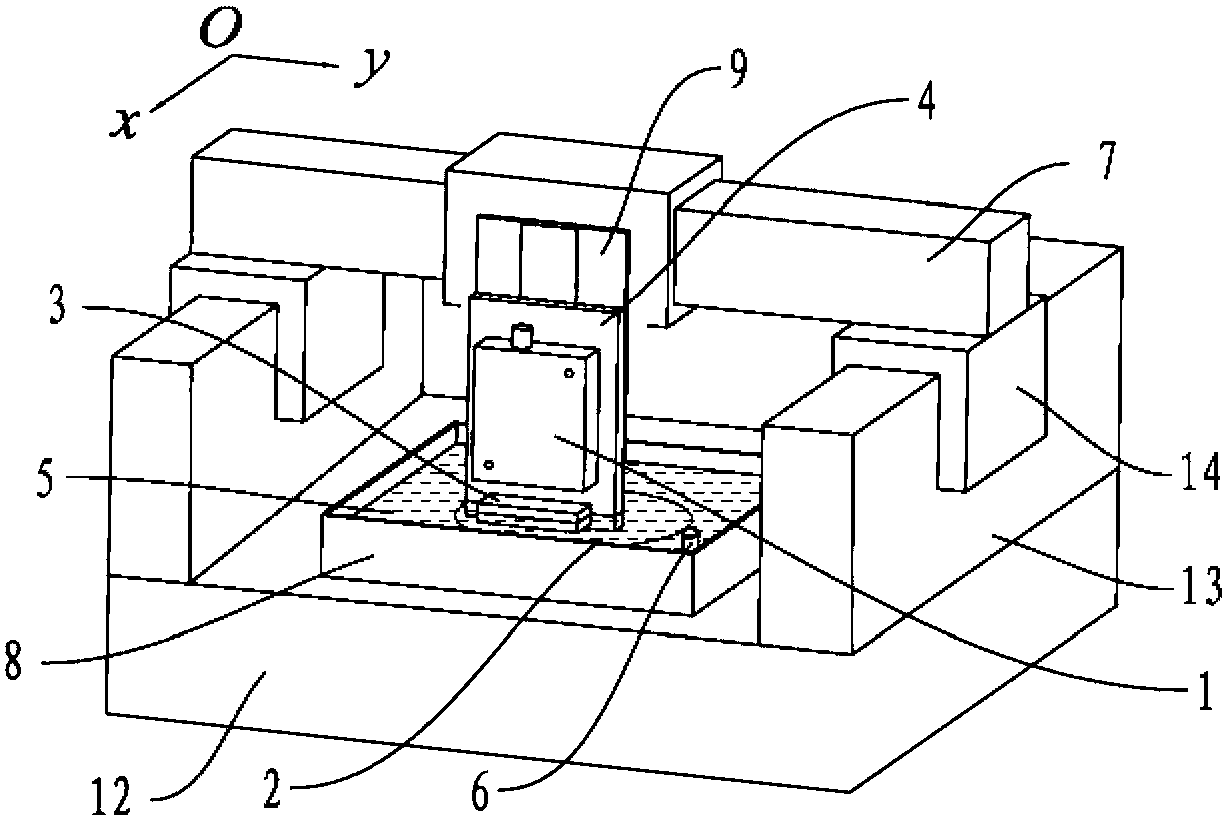

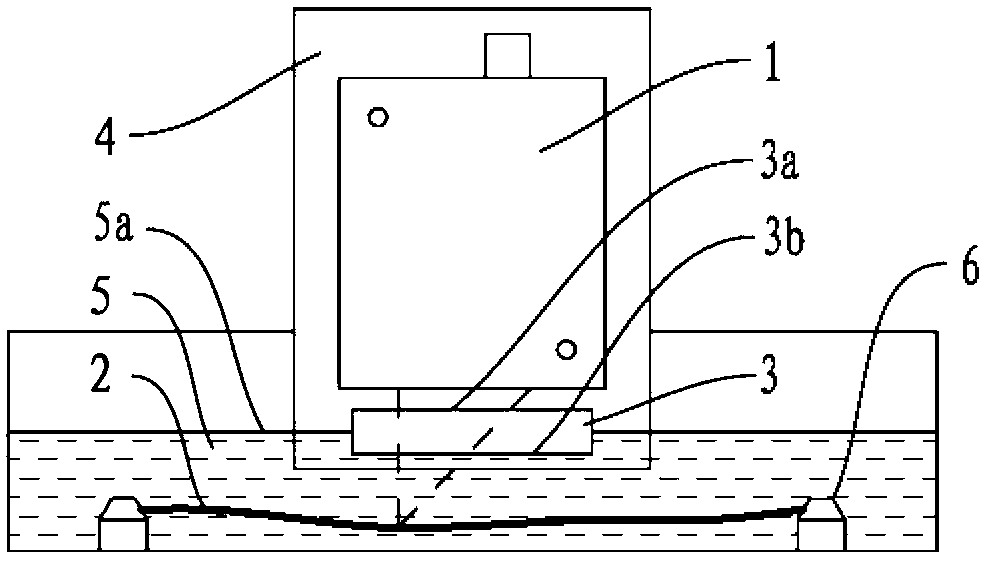

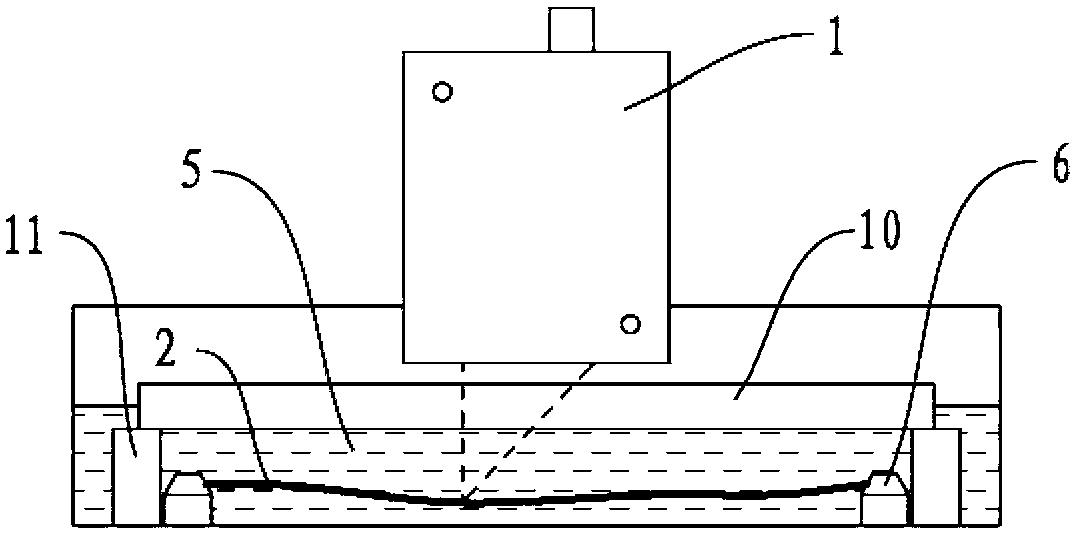

[0016] The specific implementation manners of the present invention will be further described in detail below in conjunction with the drawings and technical solutions. attached figure 1 , 2 It is embodiment 1 of the present invention, optical displacement sensor 1 adopts laser triangular displacement sensor, thin substrate 2 is a thinned silicon wafer, optical displacement sensor 1 is fixed on the vertical translation stage 9 by mounting plate 4, and the vertical translation stage 9 is adjusted before measurement. The position of the displacement stage 9 is such that the thin substrate 2 is within the measuring range of the optical displacement sensor 1 . The vertical translation platform 9 is fixed on the two-dimensional motion platform 7. In the two-dimensional motion platform 7, the right carriage 14 can move on the right column 13, and the right column 13 is installed on the workbench 12; the solution 5 adopts zinc chloride The solution is placed in the tank 8, the solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com