Preparation method of fixed-point planar-view TEM sample

A sample preparation and sample technology, applied in the field of fixed-point plane TEM sample preparation, can solve the problem of difficulty in controlling the distance between the edge and the target, and achieve the effect of improving the success rate and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the above-mentioned objects, features and advantages of the present invention more obvious and understandable, the specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings. It should be noted that the drawings of the present invention all adopt simplified forms and all use imprecise proportions, which are only used to conveniently and clearly assist in explaining the purpose of the embodiments of the present invention.

[0021] Please refer to Figure 5 And combine Figure 1~4 , A method for preparing a fixed-point planar TEM sample 100 provided by the present invention includes:

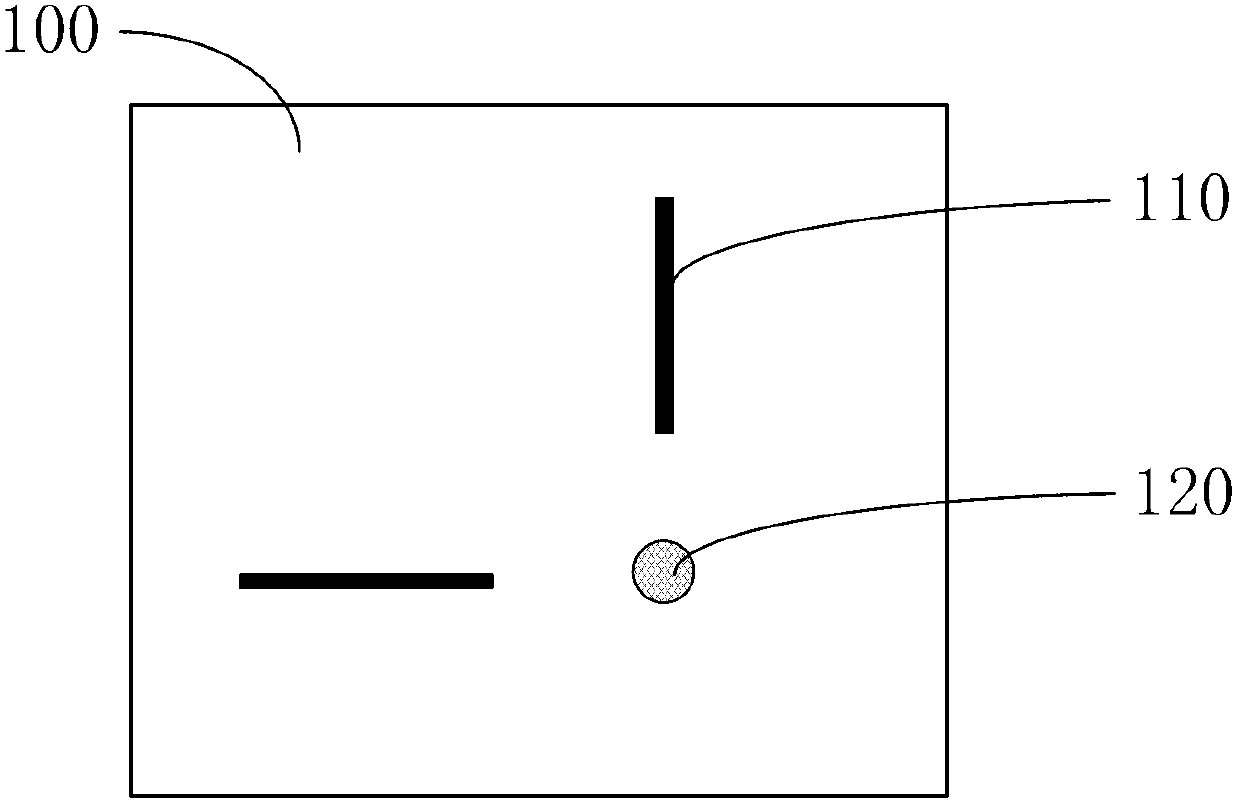

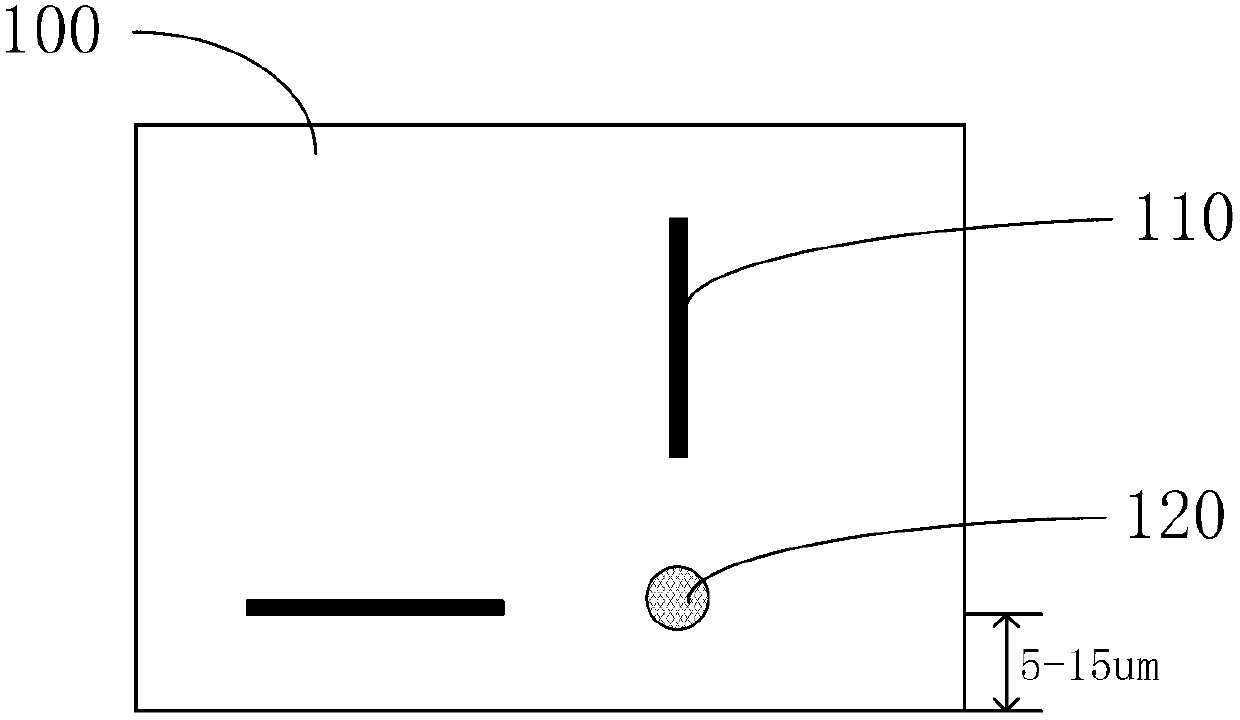

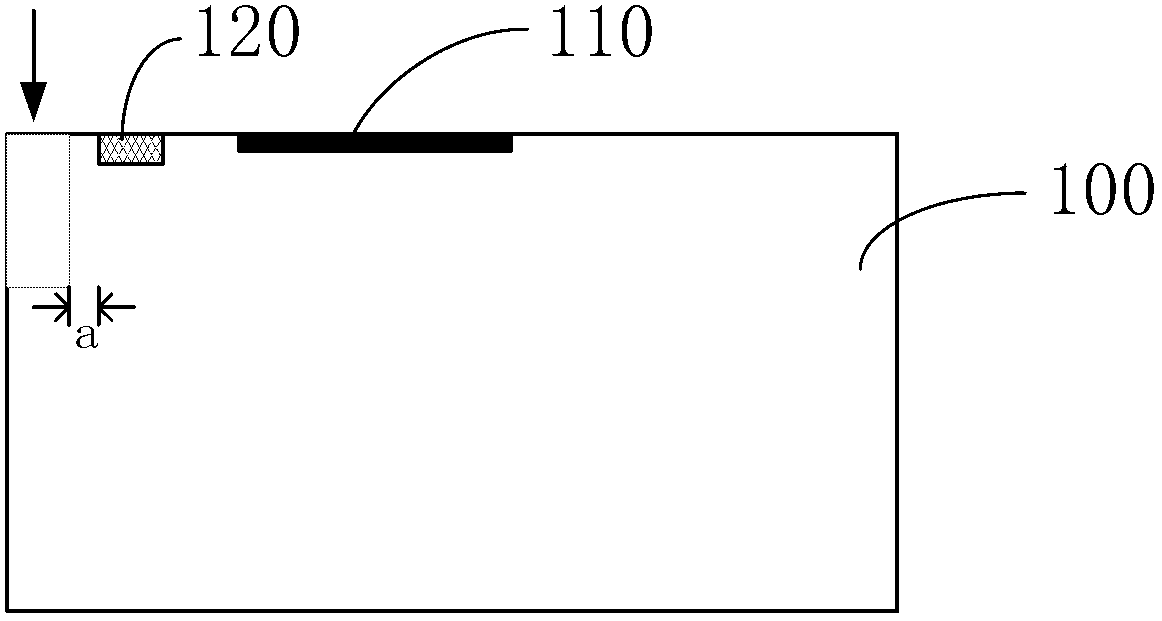

[0022] Step 1: Position the target 120 of the TEM sample 100. Preferably, a laser or a focused ion beam (FIB) is used to locate the target 120 of the TEM sample 100. Specifically, a laser or FIB is used to leave a positioning mark 110 around the target 120 to facilitate positioning of the TEM sample 100 in the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com