Device for shifting a propeller into reverse, comprising an actuator acting on a crank pin

A technology for propellers and crank pins, which is applied to the arrangement/installation of propellers, power units, engine components, etc., and can solve problems such as broken blades, engine speeding, overspeed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

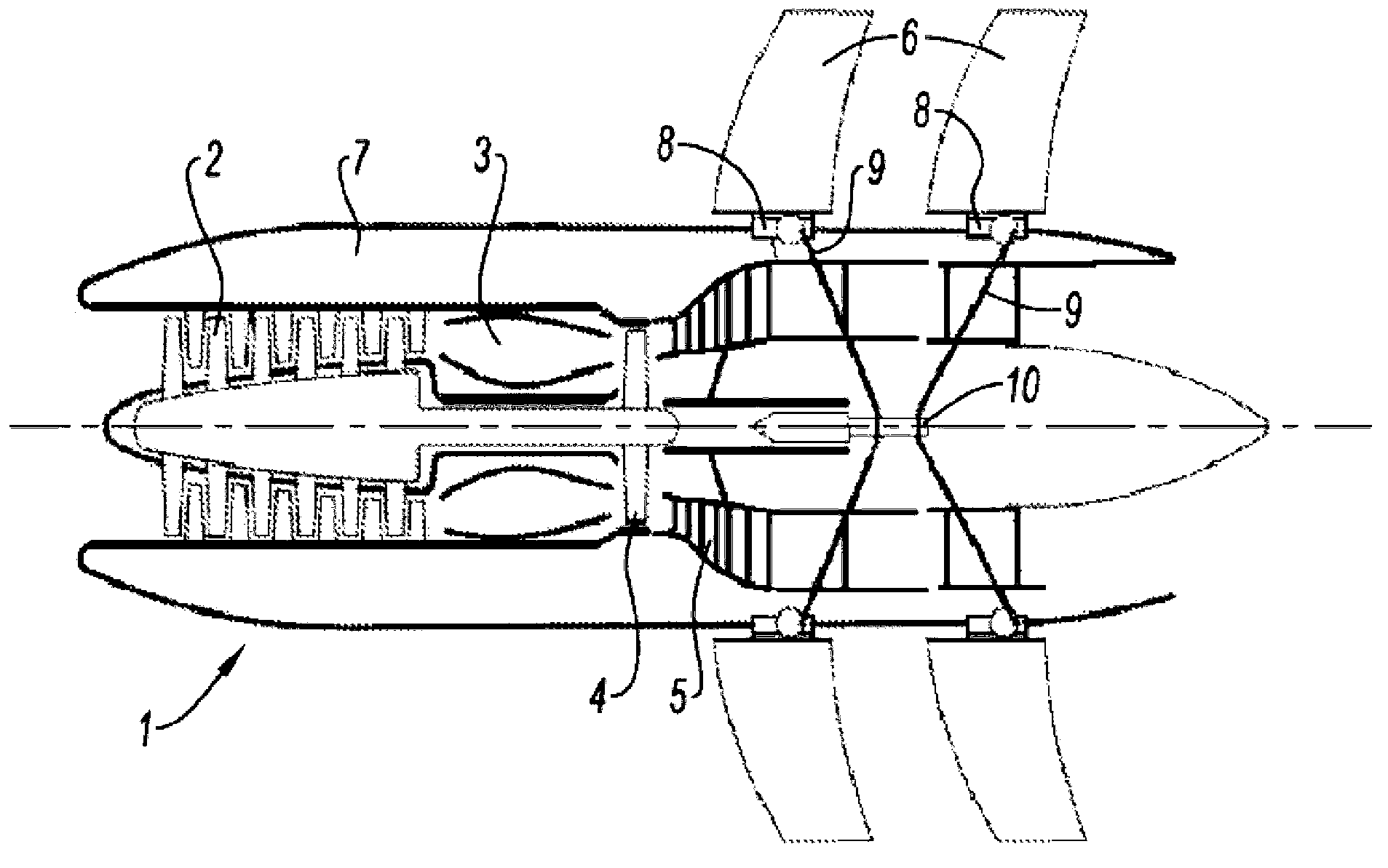

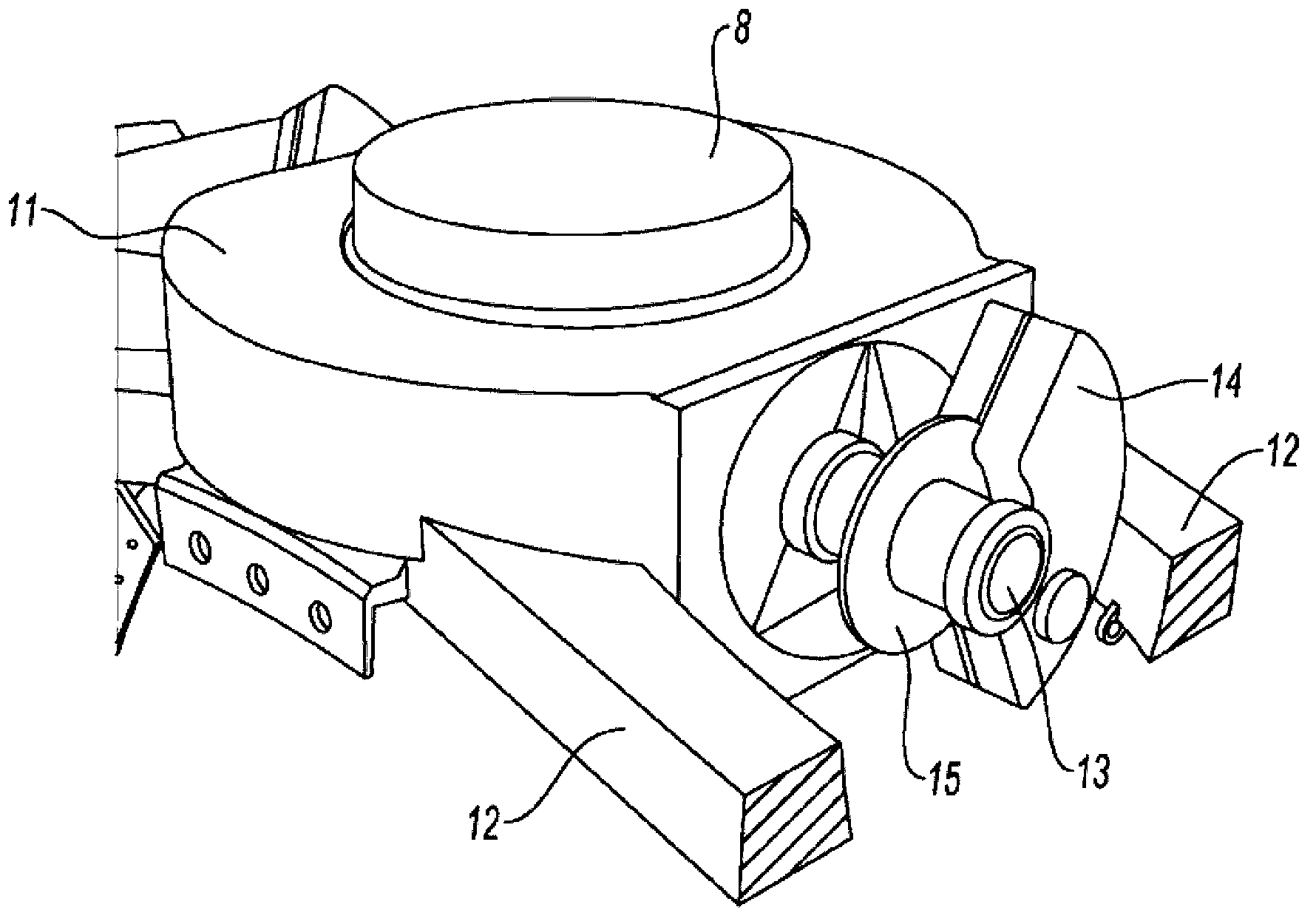

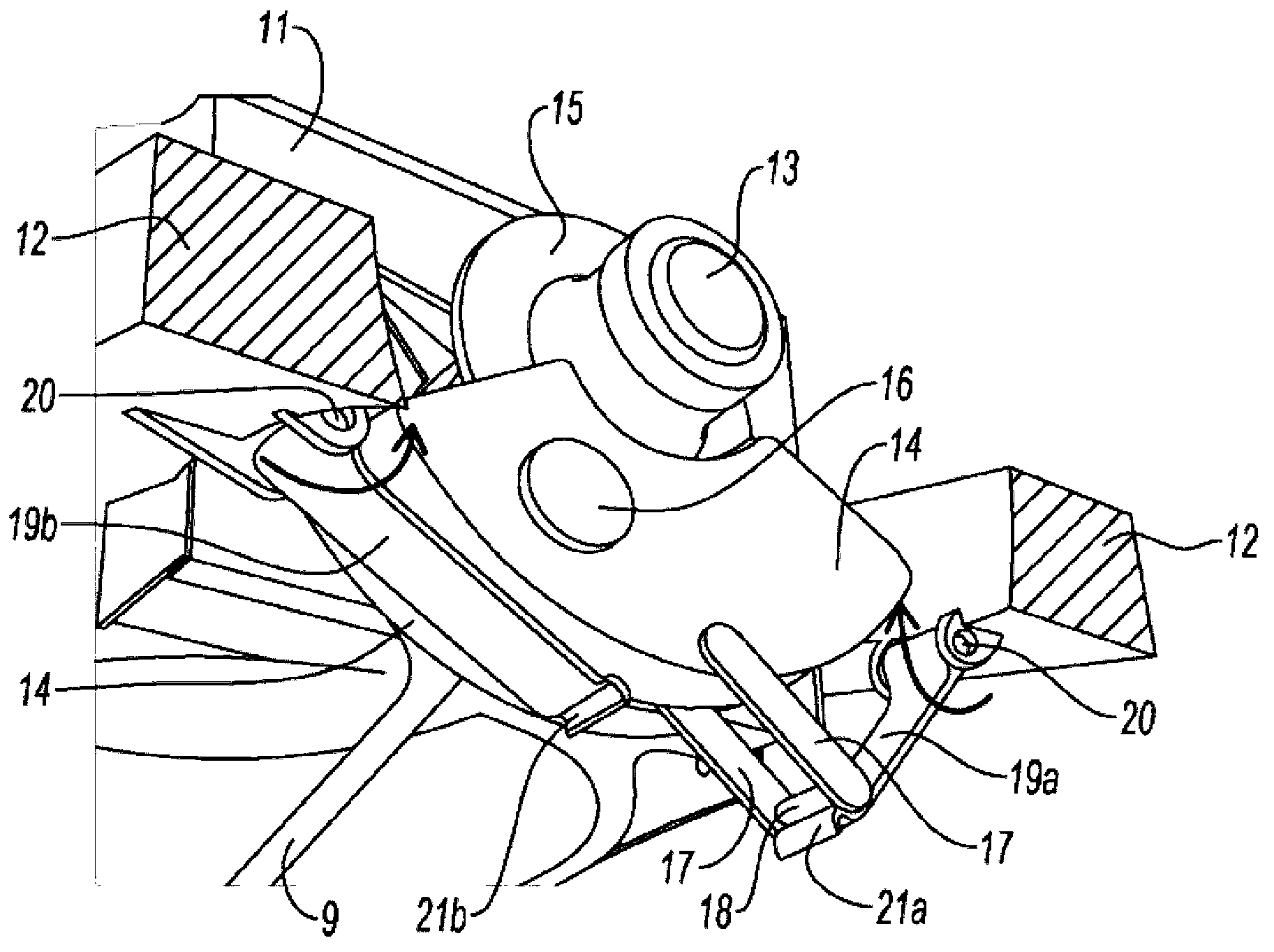

[0032] refer to figure 1, the figure shows a high-speed propeller turbine engine 1, which includes, on the one hand, a conventional gas generator, which in turn includes a compressor 2, a combustion chamber 3 and a turbine 4, the turbine 4 drives the compressor 2, and the other Aspects include, downstream of the coupling turbine 4, a free turbine 5 driving two sets of coaxial counter-rotating propellers 6 blades. The propeller is arranged outside the gas generator housing 7, and its blades are held by blade roots 8 that can rotate around an axis that is radial to the turbine 1 and passes through the center of the blade roots to form the main axis of the blades. The blade is driven to rotate by the transmission mechanism, which is in the form of a linkage device 9 and acts on a pair of helical gears, one of which is fixed on the blade and surrounds the blade root 8 . As previously stated, these helical gears are sized such that a reduction ratio of 2 is such that, when the ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com