Control cable installation structure

A technology of installation structure and cables, applied in the direction of linear motion shaft, flexible shaft, shaft, etc., can solve the problem of inclination of the installation part, achieve the effect of preventing falling off and simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

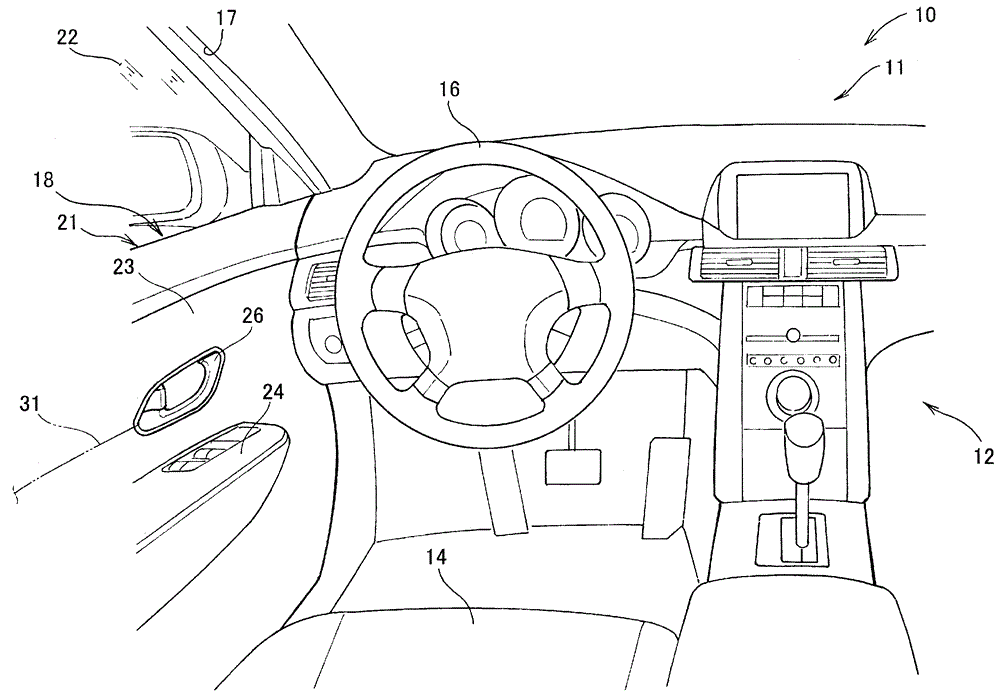

[0046] Such as figure 1 and figure 2 As shown, the vehicle 10 includes a driver's seat 14 arranged in the cabin 12 for the driver to sit on, a steering wheel 16 for manipulating the front wheels (not shown), a door opening 17 outside the driver's seat 14 for the driver to get on and off, A vehicle door 18 covering the door opening 17 in an openable and closable manner and a striker 19 provided on the door opening 17 and locking the door 18 are provided.

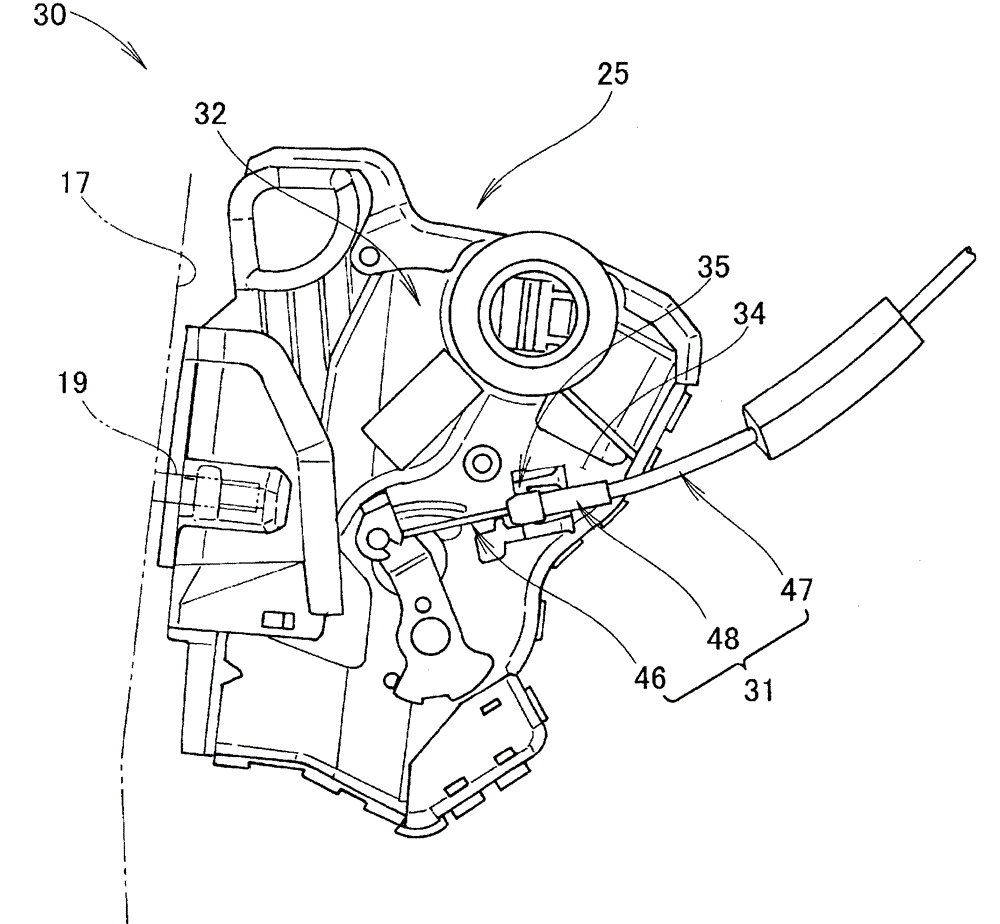

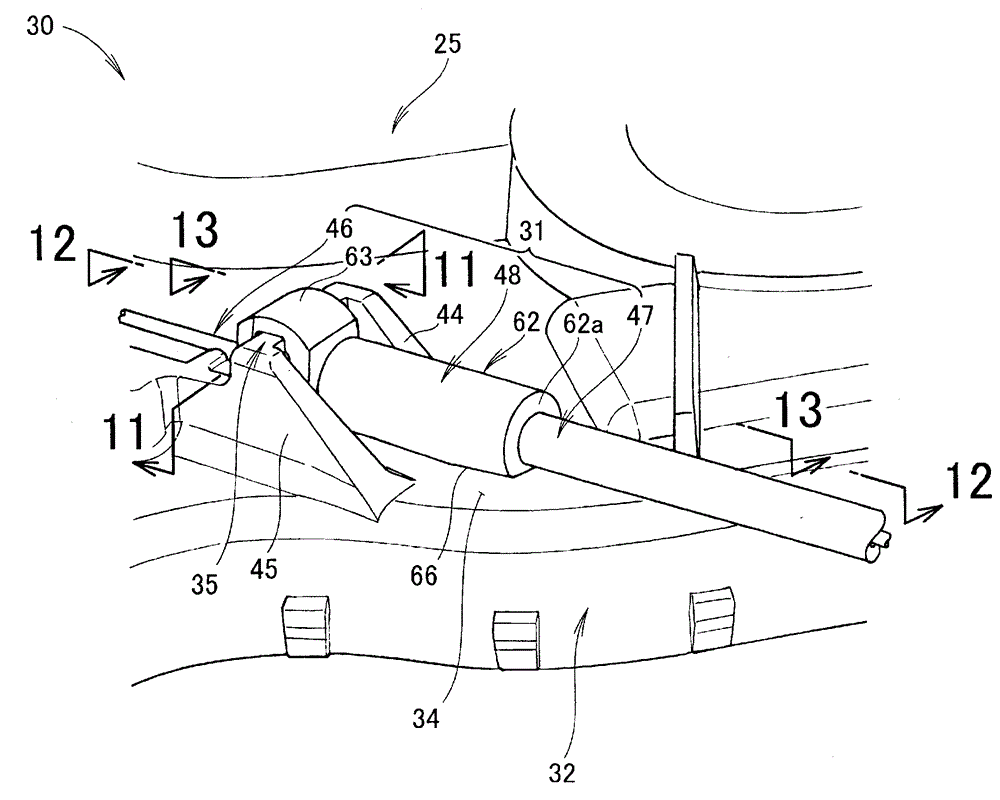

[0047] The door 18 has a door main body 21 mounted on the vehicle body 11 to be able to open and close, a door glass 22 mounted on the door main body 21 to be able to move up and down freely, and a door liner 23 covering the door main body 21 from the side of the vehicle compartment 12 so as to face The armrest 24 provided on the substantially central portion of the door liner 23 in the vertical direction so as to extend in the front-rear direction of the vehicle body, the latch mechanism 25 provided on the door main body 2...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap