Work information recording apparatus, and method and program for controlling same

A technology for operating information and recording devices, applied in the direction of comprehensive factory control, electrical program control, instruments, etc., to achieve the effect of suppressing the decline in accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

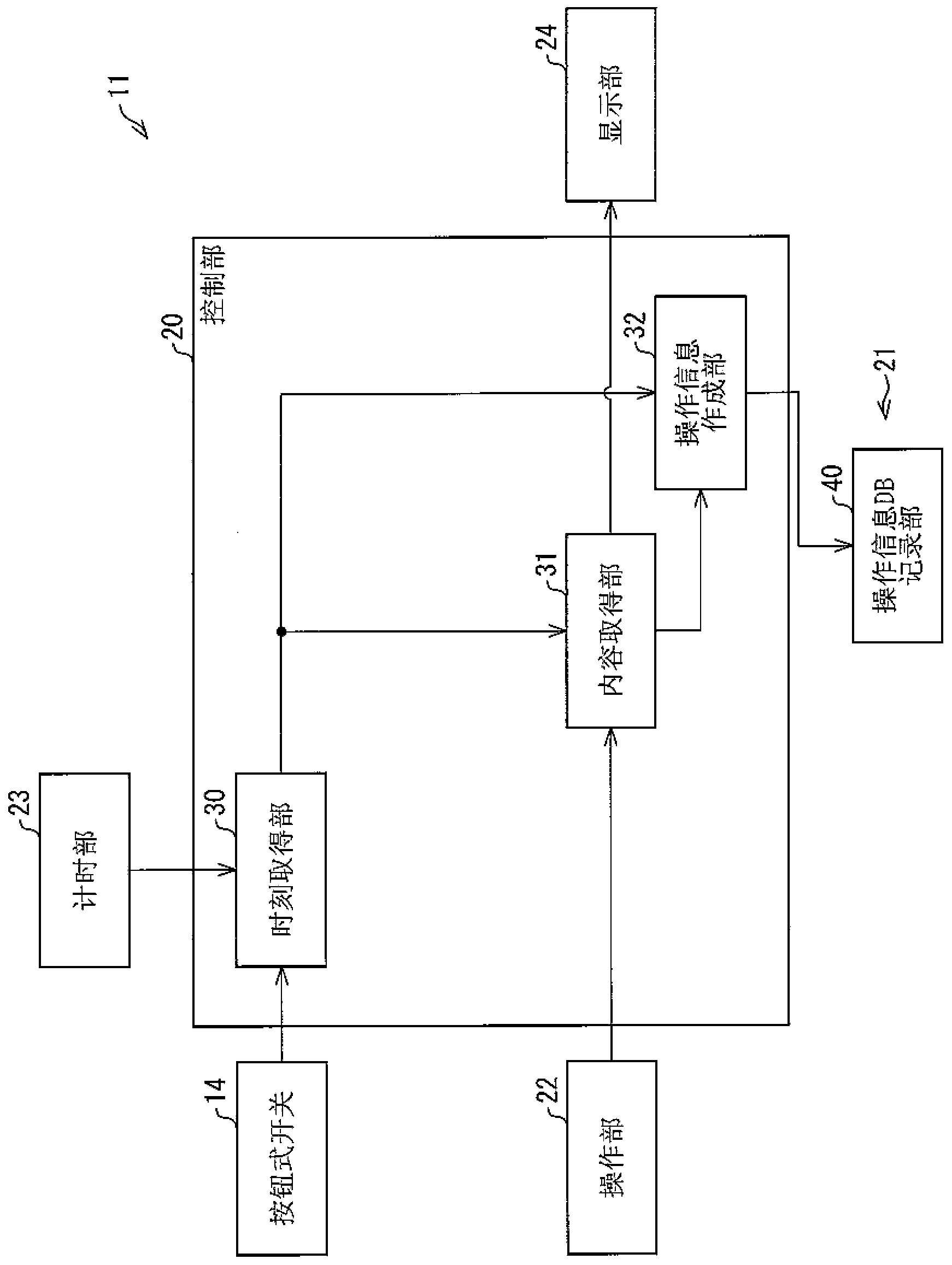

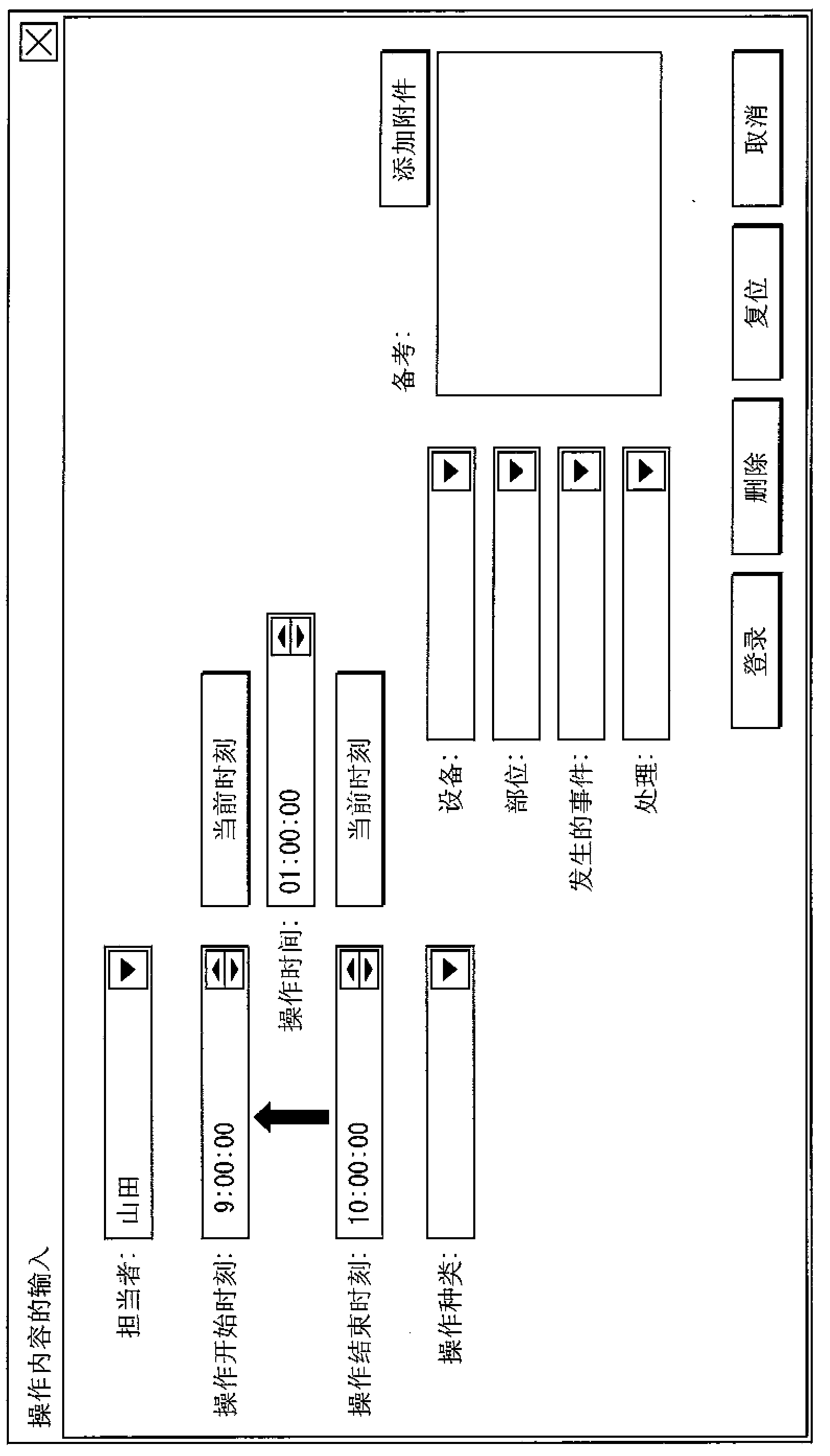

[0054] Refer to the following Figure 1 to Figure 5 One embodiment of the present invention will be described. In the present embodiment, the present invention is applied to a production system including a production line for manufacturing and assembling parts, but the present invention is not limited to the above-mentioned production system, and can be applied to various managements of processing steps of objects. The so-called treatment process of the target object refers to, for example, the production process of industrial products; the inspection process of mining and industrial products, crops or raw materials; the treatment process of waste objects (such as factory waste, factory wastewater, exhaust gas, garbage, etc.); inspection process; equipment inspection process; reuse process, etc.

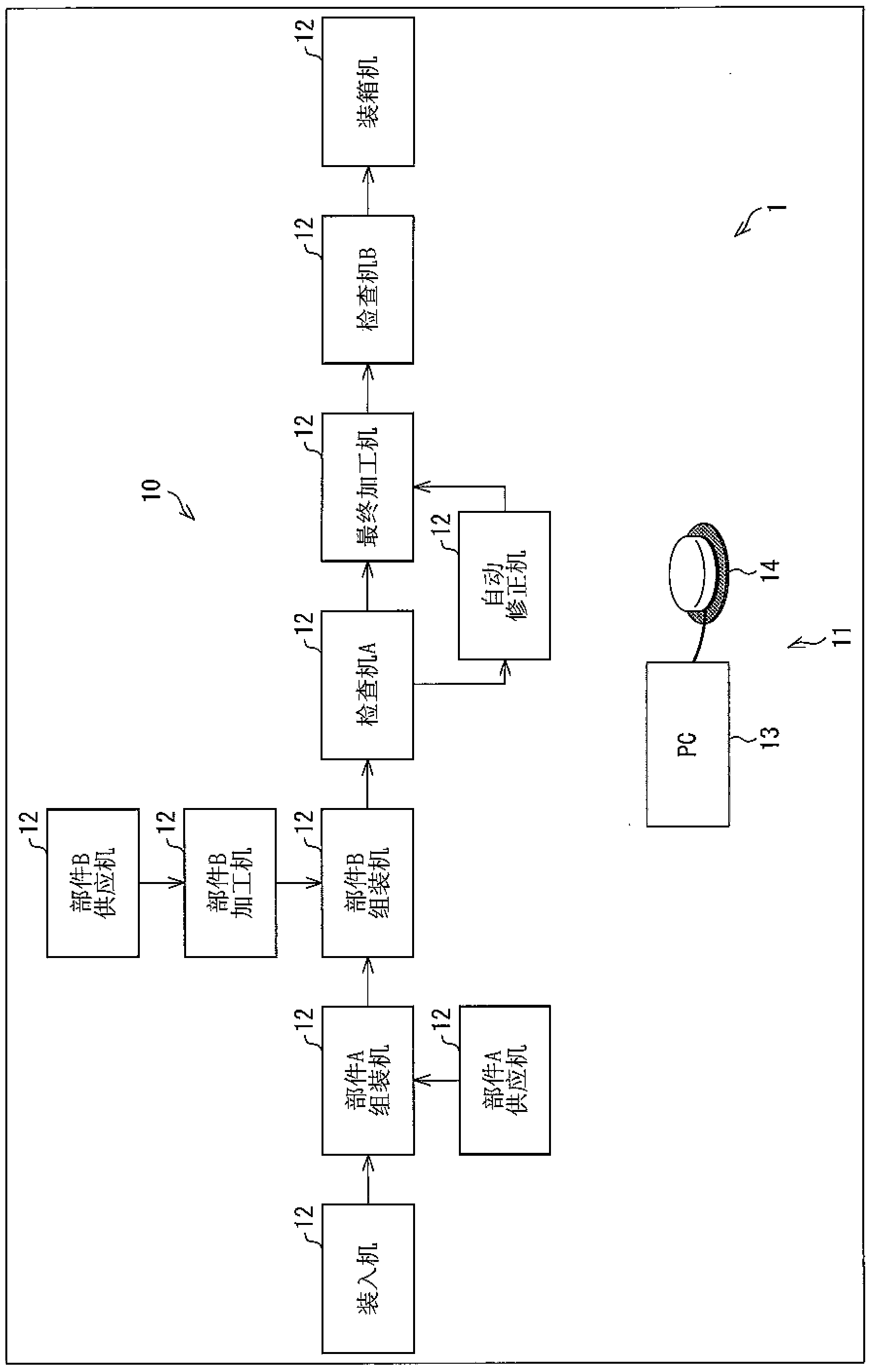

[0055] figure 2 The schematic structure of the production system of this embodiment is shown. As shown in the figure, the production system 1 includes a production line 10 and an...

Embodiment approach 2

[0075] Below, refer to Figure 6 and Figure 7 Next, other embodiments of the present invention will be described. compared to Figure 1 to Figure 5 The operation information recording device 11 shown is different from the operation information recording device 11 of this embodiment in that the push button switch 14 is replaced by an operator ID reader (action detection device, identification information reading device) 15 . Here, components having the same functions as those described in the above-mentioned embodiments are denoted by the same reference numerals and their descriptions are omitted.

[0076] The operator ID reader 15 reads the above-mentioned operator ID from a recording medium on which an operator ID (identification information) for identifying the operator is recorded, held by the operator. The operator ID reader 15 can read the operator ID from the recording medium by the operator connecting, contacting, or approaching the recording medium to the operator...

Embodiment approach 3

[0088] Below, refer to Figure 8 and Figure 9 Another embodiment of the present invention will be described. compared to Figure 6 and Figure 7 The operation information recording device 11 shown differs from the operation information recording device 11 of this embodiment only in the function of the operator ID acquisition unit 33 and the content of the log file created by the operation information creation unit 32a. As for other structural schemes, all are related to Figure 6 and Figure 7 The operation information recording device 11 shown is the same. Here, components having the same functions as those described in the above-mentioned embodiments are denoted by the same reference numerals and their descriptions are omitted.

[0089] In this embodiment, the operator ID acquisition unit 33 refers to the operator information in the operator information recording unit 41 for the operator ID acquired from the operator ID reader 15 when the time acquisition unit 30a acq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com