Cut tobacco drying technology method adopting roller pipe sheet type cut tobacco dryer to reduce BaP (benzopyrene) release amount of cigarettes

A tube-sheet type, silk drying machine technology, applied in application, tobacco, tobacco preparation, etc., can solve the problems of huge difference in release amount, large production test cost, increased difficulty in obtaining test data, etc., and achieves stable sensory quality and reduced effect of release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

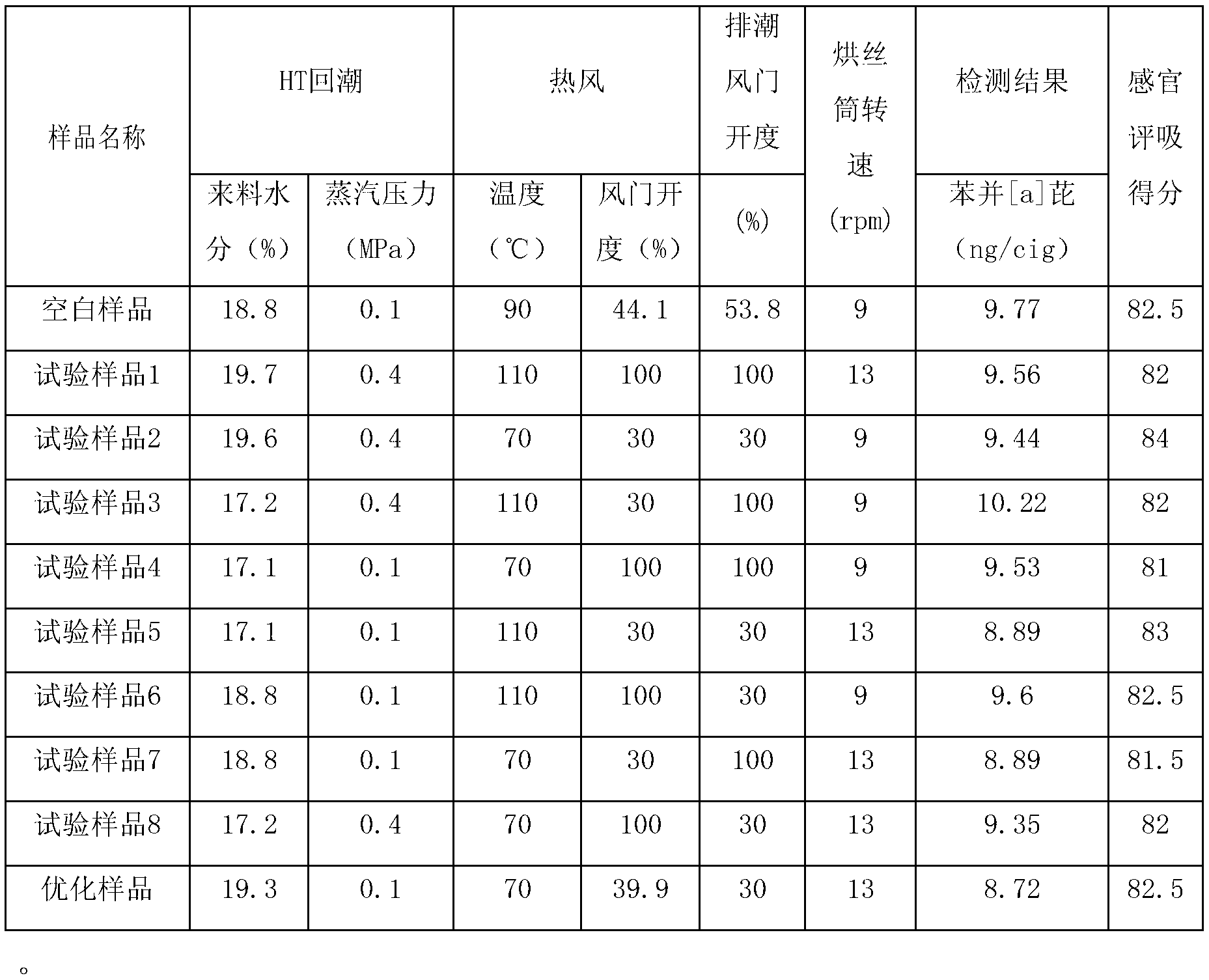

[0023] The model of the roller tube plate type wire drying machine used in this embodiment is SH314C, manufactured by Qinhuangdao Tobacco Machinery Co., Ltd. Tobacco samples produced according to the equipment parameters of the roller-tube-plate-type silk dryer in the silk-making process and drying process formulated by the enterprise are used as blank samples. In the silk-making process, the tobacco samples obtained by adjusting the process according to the following parameters are optimized samples: HT inlet moisture is 19.3%, HT steam pressure is 0.1MPa, hot air temperature is 70°C, hot air damper opening and moisture exhaust damper opening The degrees are 39.9% and 30% respectively, and the rotating speed of the silk drying cylinder is 13rmp. The tobacco samples obtained by adjusting the test parameters in the drying process were the test samples. The benzo[a]pyrene emissions and sensory evaluation scores of the three samples are shown in Table 1.

[0024] Table 1:

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com