A kind of biomass superfine powder preparation device and preparation method thereof

A biomass and ultra-fine powder technology, which is applied in chemical instruments and methods, solid separation, grain processing, etc., can solve problems such as difficulty in meeting production and research needs, inability to adjust, coarse material particle size, etc., to achieve smooth feeding, No dust pollution, good air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

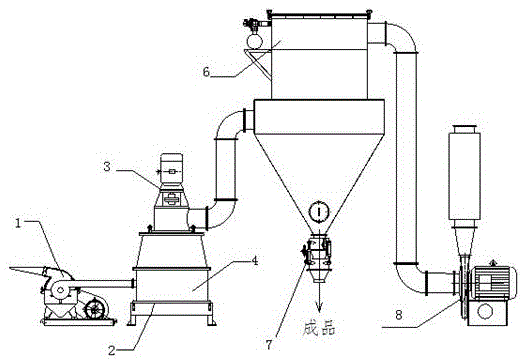

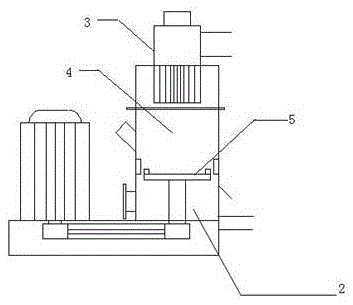

[0011] A kind of biomass superfine powder preparation device and preparation method thereof, such as Figure 1-2 Shown: It consists of a coarse pulverizer (1), a special ultrafine pulverizer for biomass (2), a pulse bag filter (6), a double-layer plate discharge valve (7) and an induced draft fan (8). The coarse pulverizer (1) is connected with the special ultrafine pulverizer for biomass (2) through pipelines, and the superfine pulverizer for biomass (2) is equipped with a pulverization chamber (4) and a classifier (3) sequentially from bottom to top; Substance-specific ultrafine pulverizer (2) and classifier (3) are integrated structure, pulverization and classification can be carried out continuously and synchronously; biomass-specific ultrafine pulverizer (2) adopts a high line speed of 120-150m / s to achieve Effective crushing; the crushing chamber (4) is equipped with a rotating millstone (5); the millstone (5) is a hammer impact mill; the classifier (3) is equipped with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com