Wheel rim coiling and rounding machine

A technology of rolling machine and rim, which is applied in the field of rim manufacturing process and rim rolling machine, which can solve the problems of wasting resources, reducing production efficiency and increasing labor cost, and achieves the effects of reducing labor cost, improving production efficiency and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

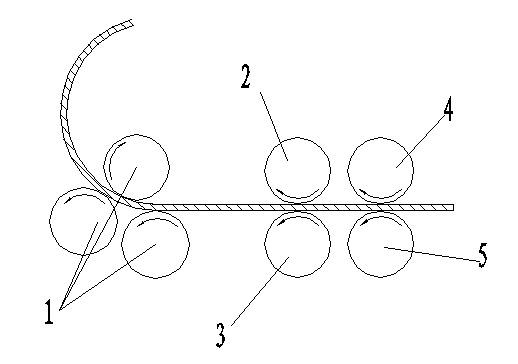

[0010] The present invention comprises a frame, and the front end of the frame is provided with a rolling mechanism 1 composed of three roller shafts, and it is characterized in that, the horizontal front end of the rolling mechanism 1 is provided with a forced feeding mechanism and a character rolling mechanism; The forced feeding mechanism is composed of a steel upper forced feeding roller 2 and a lower forced feeding roller 3 with anti-skid grooves, and the upper forced feeding roller 2 is driven by a hydraulic motor; the character rolling mechanism It is composed of a steel upper lettering roller 4 and a lower lettering roller 5 with antiskid grooves, and the upper lettering roller 4 is driven by a hydraulic motor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com