Tube bending and forming mechanism

A forming mechanism and pipe bending technology, applied in the field of pipe bending forming mechanism, can solve problems such as low production efficiency, failure to meet large-scale production needs, lack of continuity in processing, etc., and achieve continuous production and smooth production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

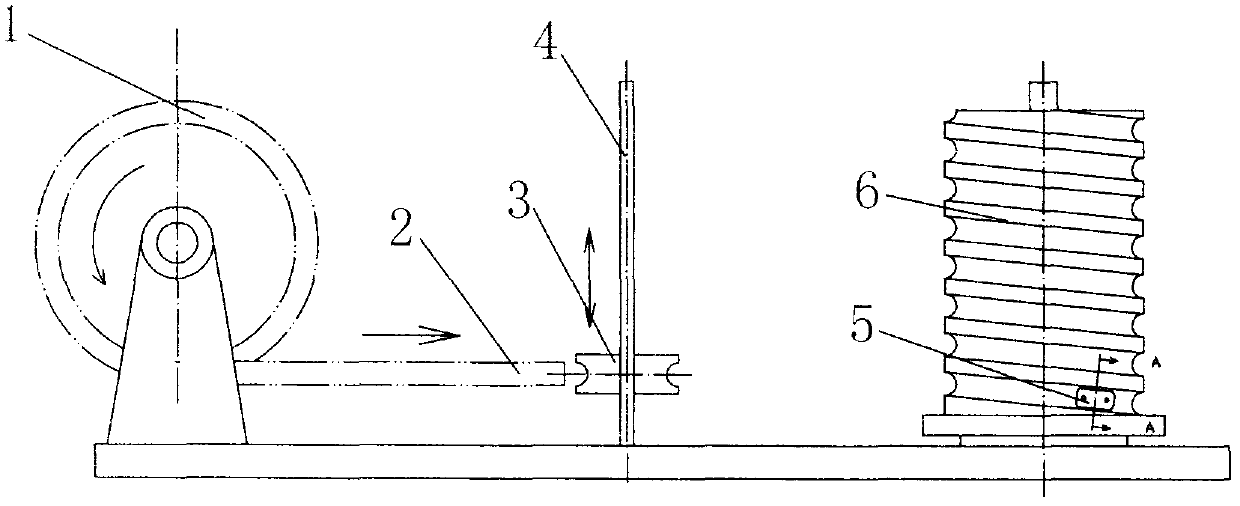

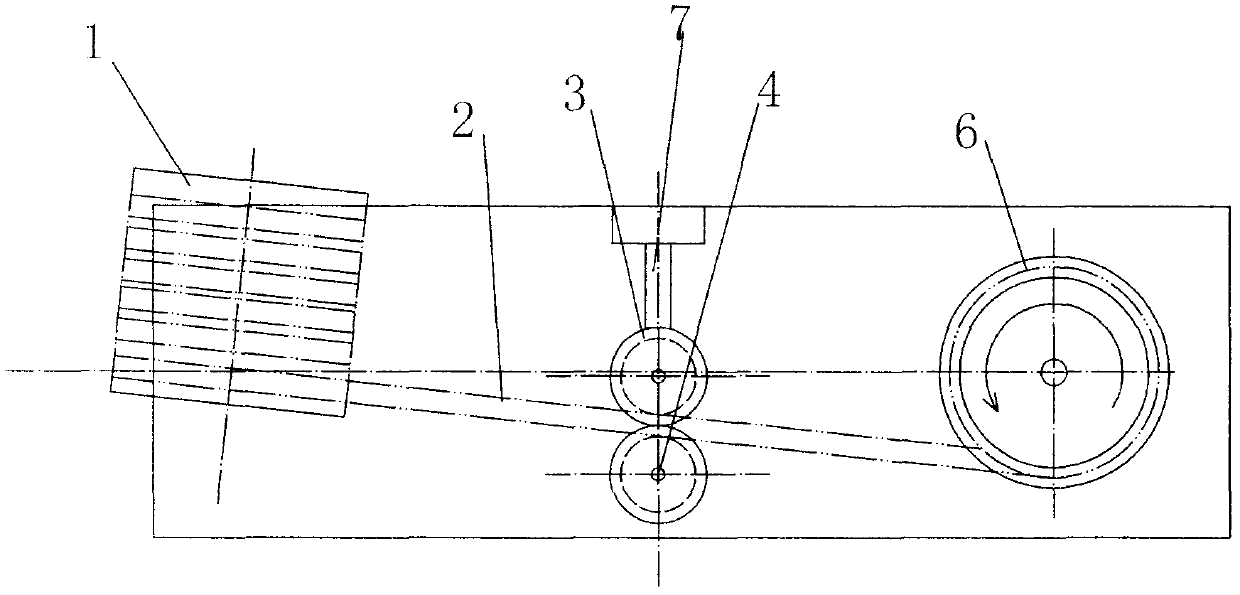

[0018] The present invention includes a frame, a pipe delivery mechanism and a pipe bending mechanism 6 arranged on the frame; wherein the pipe delivery mechanism 6 includes a delivery mechanism 1 and a pipe discharge mechanism arranged between the delivery mechanism 1 and the bending mechanism 6, The pipe release mechanism includes a shaft 4 vertically arranged on the frame, and a roller 3 that can move up and down along the shaft 4 is sleeved on the shaft 4. The roller 3 is provided with an annular concave surface that cooperates with the tube blank 2; The mechanism 6 includes a rotating cylinder, the outer circumference of which is processed into a spiral groove corresponding to the tube blank 2, the lower end of the bending mechanism 6 is provided with a clamp 5 for fixing the end of the tube blank 2; the roller 3 is on the shaft 4 The speed of movement corresponds to the rotational speed of the cylinder.

[0019] The pipe releasing mechanism of the present invention is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com