Drilling marking-off method of equal-spaced holes

A drilling scribing and equidistant technology, applied in the field of mechanical processing, can solve the problems of increasing processing cost, low scribing accuracy, and large number of holes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

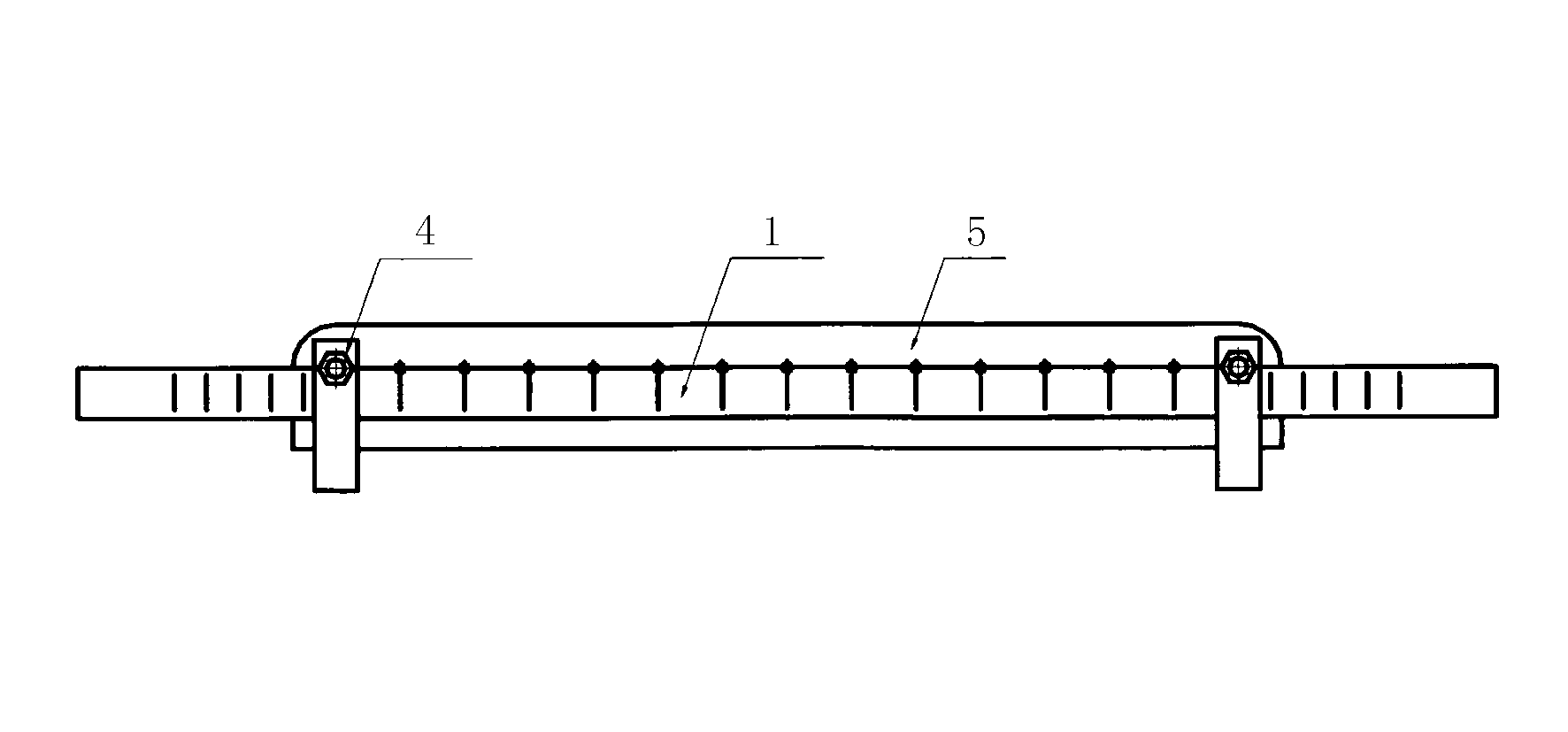

[0018] A method for drilling and marking equidistant holes, comprising the following steps:

[0019] 1) Take a rubber band with a rectangular cross-section and a length of 500mm, stretch it to 3 times the original length, and fix the two ends of the rubber band on the wooden board with a screw clamp;

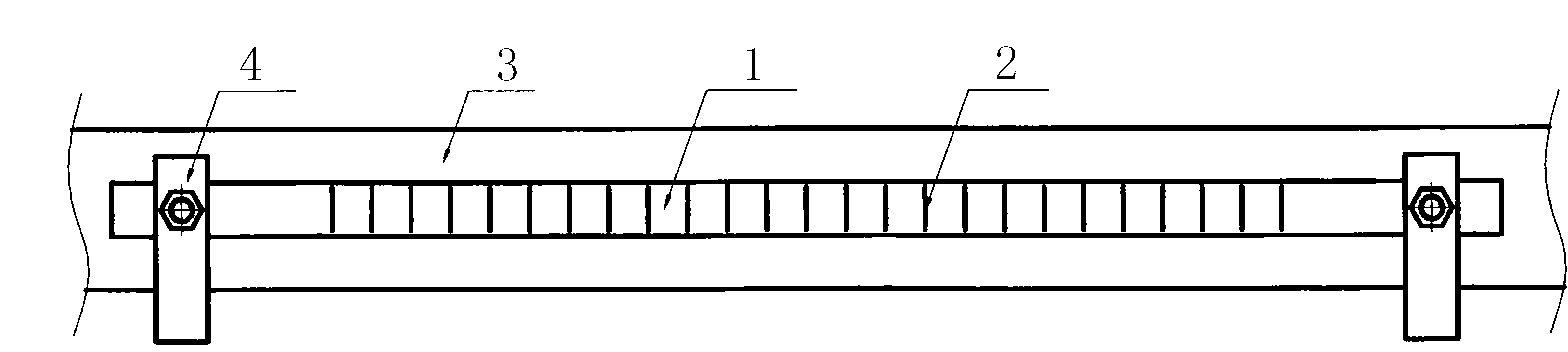

[0020] 2) if figure 1 As shown, use a ruler and an ink pen to draw 25 equidistant parallel straight lines with a line width of 0.5mm and a spacing of 50mm on the stretched rubber band, and then remove the rubber band from the wooden board;

[0021] 3) Use an ink pen to draw the center point of the hole at both ends of the equidistant hole on the surface of the part according to the size, and the diameter of the center point drawn is a circle point with a diameter of Ф1mm;

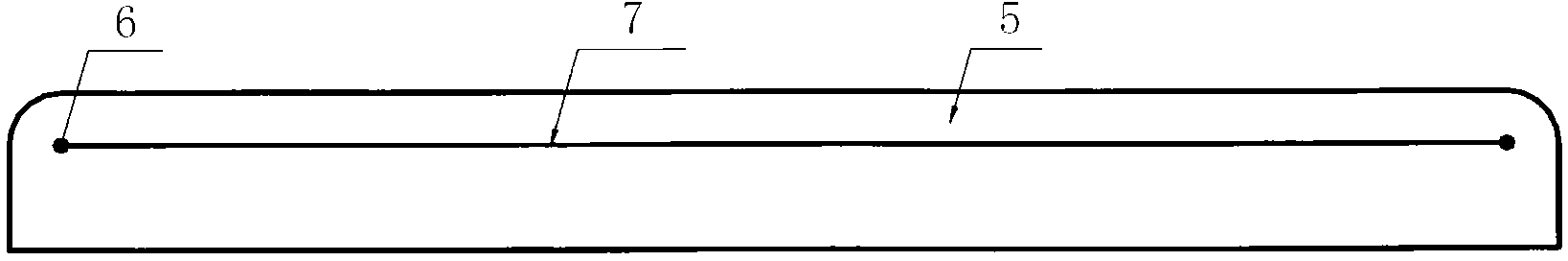

[0022] 4) if figure 2 As shown, with the center of the two dots as the endpoint, use a ruler and a pencil to draw a straight line segment with a line width of 0.5mm on the plane of the part;

[0023] 5) A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com