Heavy duty pneumatic tire

A technology for pneumatic tires and heavy loads, applied in the field of pneumatic tires for heavy loads, can solve problems such as difficulty in achieving low fuel consumption and wear resistance, and achieve improved low fuel consumption, uneven wear resistance, and excellent uneven wear resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

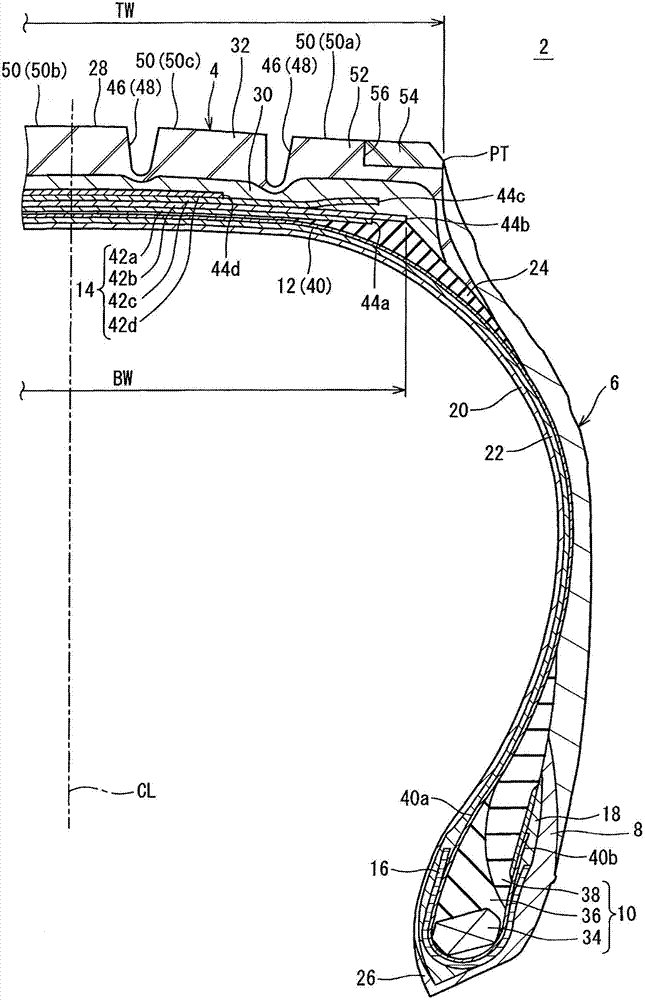

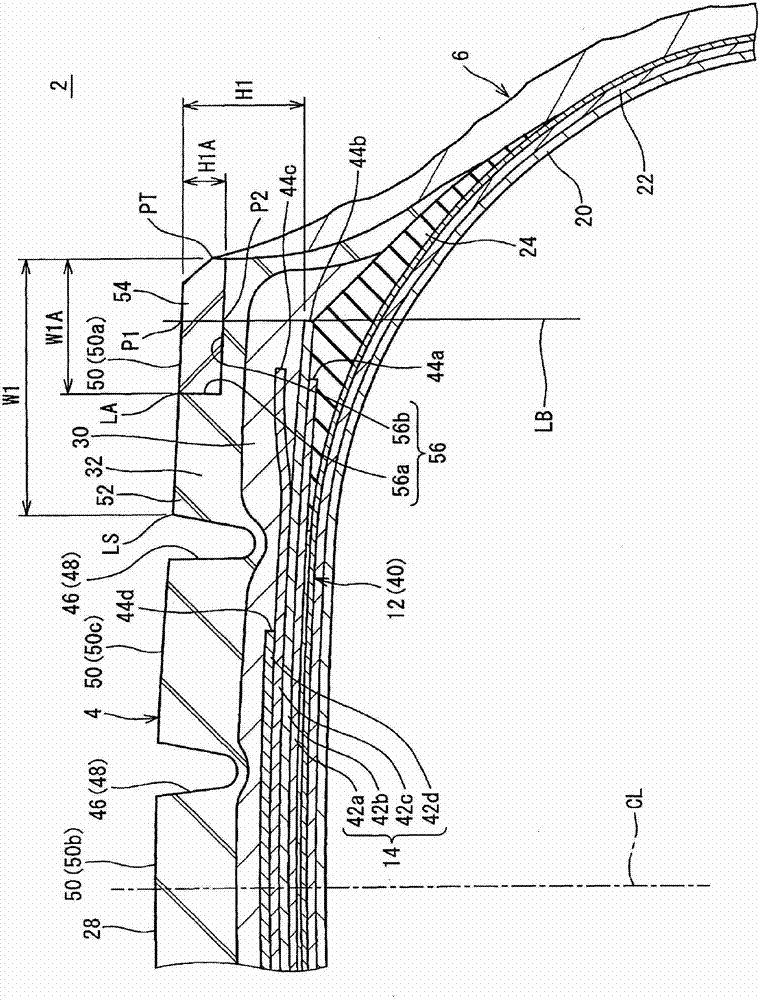

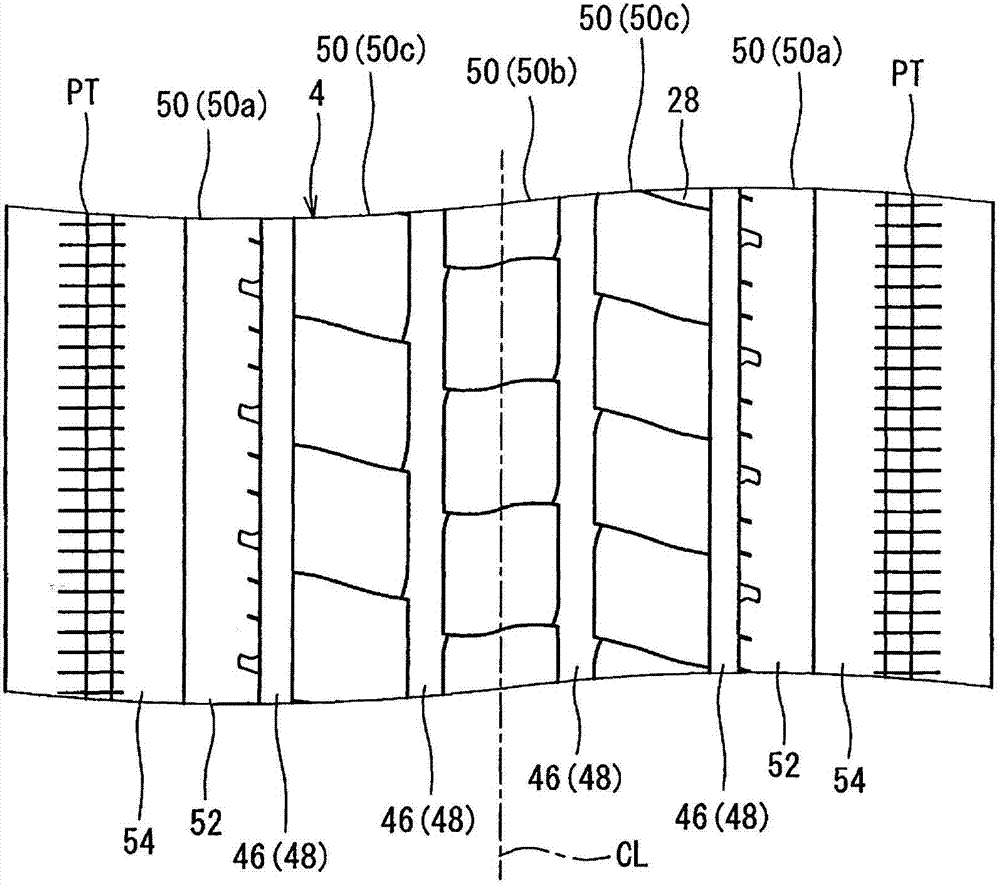

[0101] get to have figure 1 A pneumatic tire for heavy loads according to Example 1 having the basic structure shown in Table 1 below. The size of the tire is 12R22.5. The ratio (P1A / P1B) of the average ground contact pressure P1A of the outer contact patch of the shoulder land portion to the average contact contact pressure P1B of the inner contact patch was 0.90. The ratio (BW / TW) of the width BW of the belt to the width TW of the tread was 0.98. The complex elastic modulus E1A of the buffer is 5.70 MPa. The loss tangent L1A of this buffer was 0.115. The complex elastic modulus E1B of the main body is 5.10 MPa. The loss tangent L1B for this subject is 0.075. The ratio of the thickness H1A of the shock absorber to the thickness H1 of the shoulder land portion was 0.33. The ratio of the width W1A of the shock absorber to the width W1 of the shoulder land portion is 0.50.

Embodiment 2-3 and comparative example 1-2

[0103] Tires were obtained in the same manner as in Example 1 except that the ratio (P1A / P1B) was set in accordance with Table 1 below.

Embodiment 4-5 and comparative example 8-9

[0107] Tires were obtained in the same manner as in Example 1 except that the ratio (H1A / H1) and the ratio (W1A / W1) were set in accordance with Table 3 below.

[0108] Occurrence of partial wear and amount of wear 1

[0109] Install the test tires on high-speed buses. The rims measure 8.25×22.5. The internal pressure of the tire was adjusted to 800 kPa. Under full load, the high-speed bus has traveled 30,000 km. After running, the state of occurrence of partial wear of the tire mounted on the front wheel was visually observed, and the wear amount of the shoulder land portion of the tire was measured. The results are shown in Tables 1 to 3 below. In the table, "D" is indicated when shoulder chip wear or step wear is confirmed, and "-" is indicated when it is not confirmed.

[0110] Fuel consumption performance

[0111] The average fuel consumption (distance traveled per 1 liter of gasoline) was measured for 5 high-speed buses traveling 30,000 km. The average values the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Complex elastic modulus | aaaaa | aaaaa |

| Complex elastic modulus | aaaaa | aaaaa |

| Complex elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com