Automatic conveying device

A transmission device and automatic technology, applied in the direction of conveyor control devices, transportation and packaging, conveyor objects, etc., can solve the problems of falls, low transportation efficiency, smashing injuries, etc., to reduce energy waste, reduce labor intensity, The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

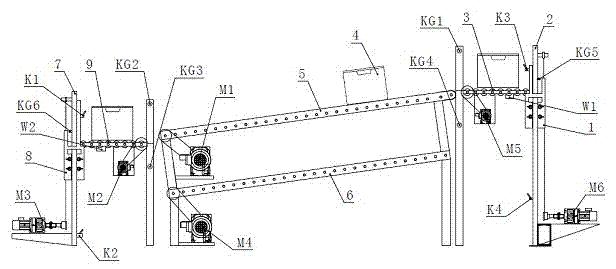

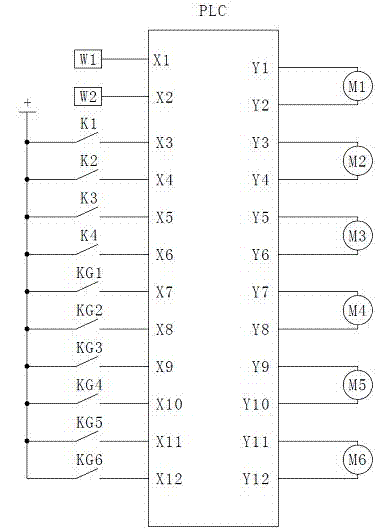

[0014] see figure 1 , figure 2 , the present invention includes item box 4, feeding elevator (including lifting table 1 of feeding elevator, vertical slideway 2 of feeding elevator, feeding roller 3, feeding motor M5, lifting drive motor M6 of feeding elevator), receiving elevator (including receiving elevator) Material elevator vertical slideway 7, lifting table 8 of material receiving elevator, material receiving roller 9, material receiving motor M2, lifting drive motor M3 of material receiving elevator), upper conveyor belt 5, lower conveyor belt 6 and intelligent control system. Its working process is as follows:

[0015] Load the material to be conveyed into the item box 4 located on the upper part of the feeding elevator. When the weight of the item box 4 reaches or exceeds the set value, the first gravity sensor W1 sends the corresponding electrical signal to the PLC, and the PLC collects the signal. Start the feeding motor M5, and the feeding motor M5 drives the fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com