Gas mixing device for photovoltaic glass sputtering manufacture procedure

A technology of gas mixing device and photovoltaic glass, which is applied in the direction of sputtering plating, ion implantation plating, metal material coating process, etc., can solve the difficult and effective control of film ratio, increase the flow rate of gas filling, and cannot effectively achieve Deposited film ratio and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

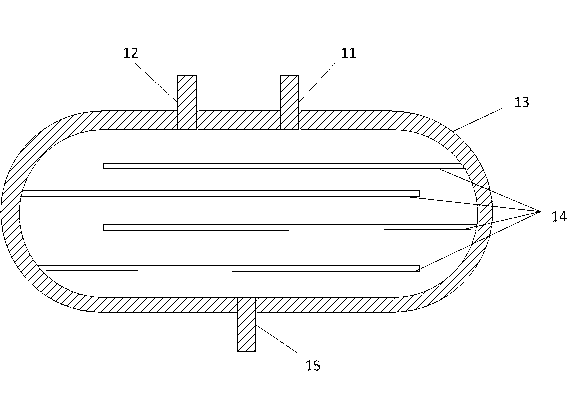

[0013] In order to make it easier to understand other features and advantages of the present invention and the effects achieved, the present invention will be described in detail as follows in conjunction with the accompanying drawings: Please refer to figure 1 The main purpose of the present invention is to provide a gas mixing device for photovoltaic glass sputtering process, which is to connect the stainless steel inner polishing container 13 to the front of the intake pipe through the gas outlet 15 through the ferrule connection tube, and the other end of the stainless steel inner polishing container 13 Then connect the two kinds of reaction gases required by the gas inlets 11 and 12 with ferrules, and 4 gas partitions 14 are arranged inside the stainless steel polishing container 13, with a thickness of 3 mm and a length of 150 mm. There is a distance of 50mm between the plates 14, which are arranged symmetrically in the stainless steel inner polishing container 13, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com