Textile machine with movably fixed suction element

A suction element and textile machine technology, applied in spinning machines, textiles, papermaking, drafting equipment, etc., can solve the problems of difficult maintenance and difficulty in getting close to each suction element, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

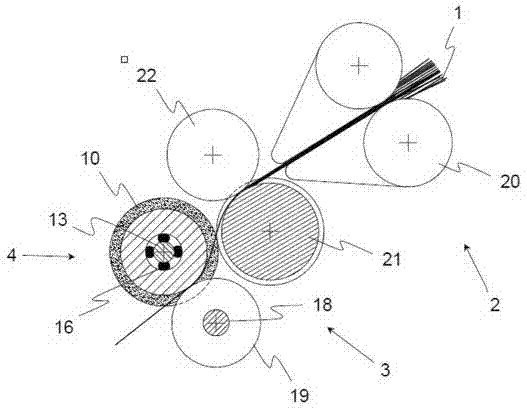

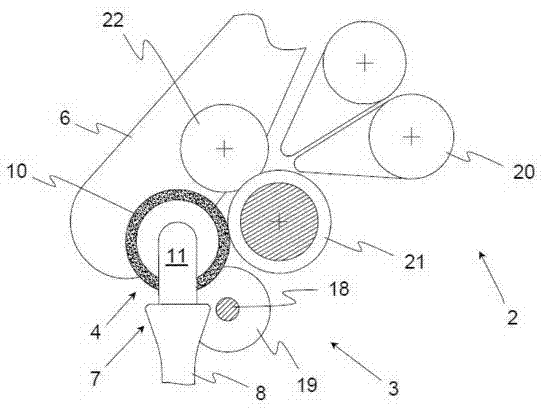

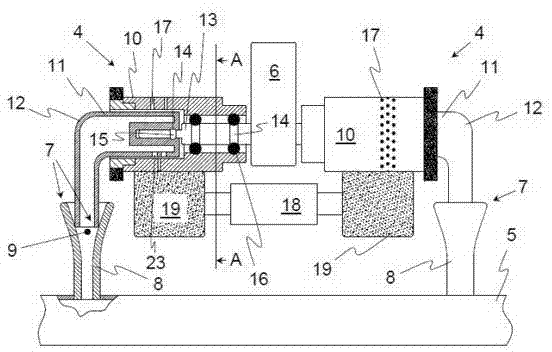

[0030] from Figures 1 to 4 The essence of the present invention can be learned from the summary in, wherein Figures 1 to 4 is a sectional view of a possible embodiment of a textile machine according to the invention, for example a ring spinning machine.

[0031] In general, a textile machine comprises a plurality of spinning stations arranged in a row, wherein a corresponding drafting device is arranged in each spinning station, by means of which a bundle of fine threads of the fiber composite material 1 introduced is processed. A stretching treatment followed by a compression treatment. Finally, the fiber composite material 1 that has undergone the above-mentioned processing steps enters a downstream spinning unit, where it is spun into yarns.

[0032] In this example, the drafting device comprises a drafting zone 2, wherein the drafting zone 2 comprises a pair of molding rolls 20 and a pair of trailing rolls. In this case, the end roll pair can have a centrally driven l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com