Pillar packaging structure

A technology for packaging structures and pillars, applied in building structures, natural mineral layered products, covering/lining, etc., can solve the problems of complex process, insufficient structure, inability to meet moisture-proof, heat-insulation, sound-absorbing and other problems, and achieve beautiful appearance , Improve the effect of aesthetics and practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the embodiments of the drawings.

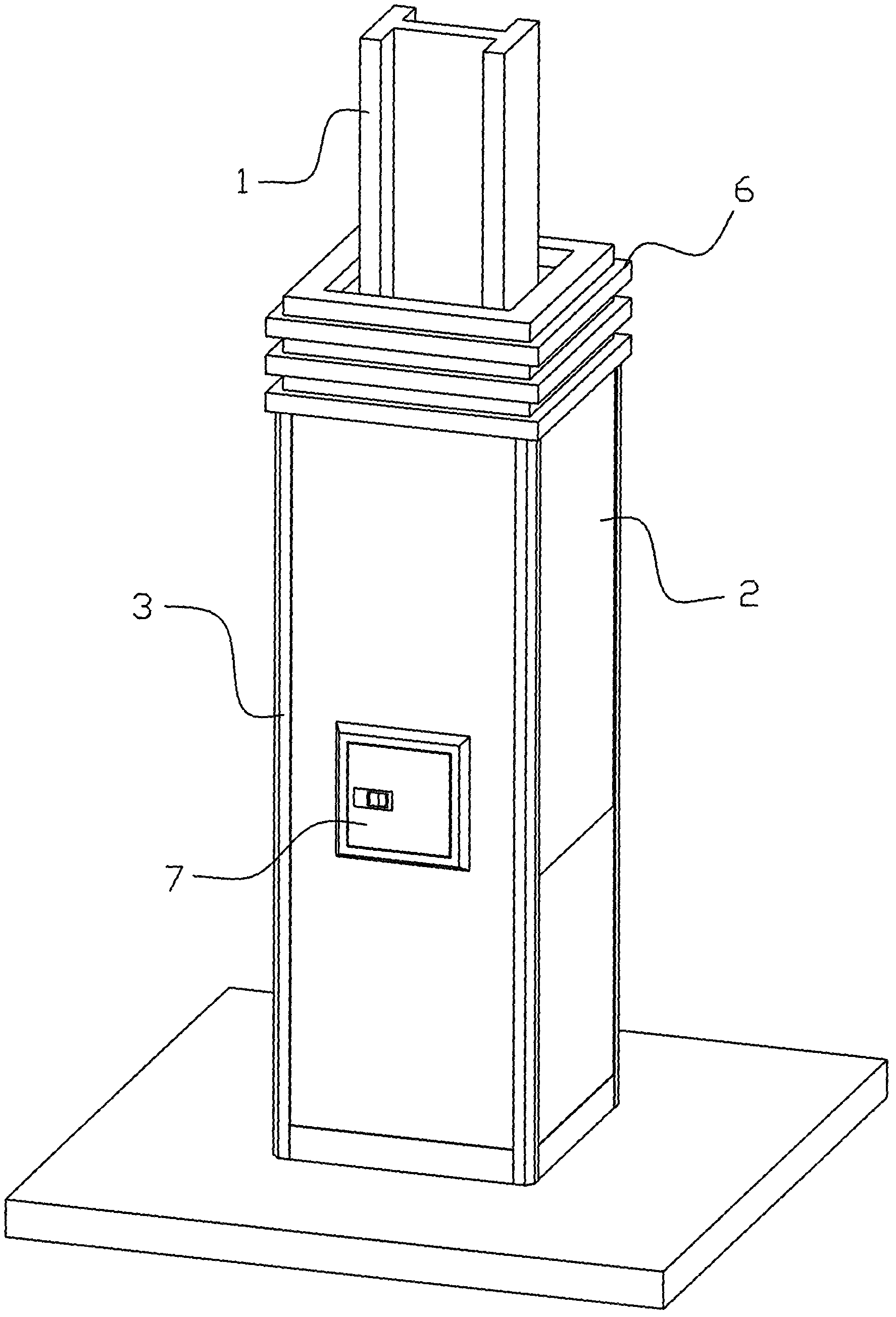

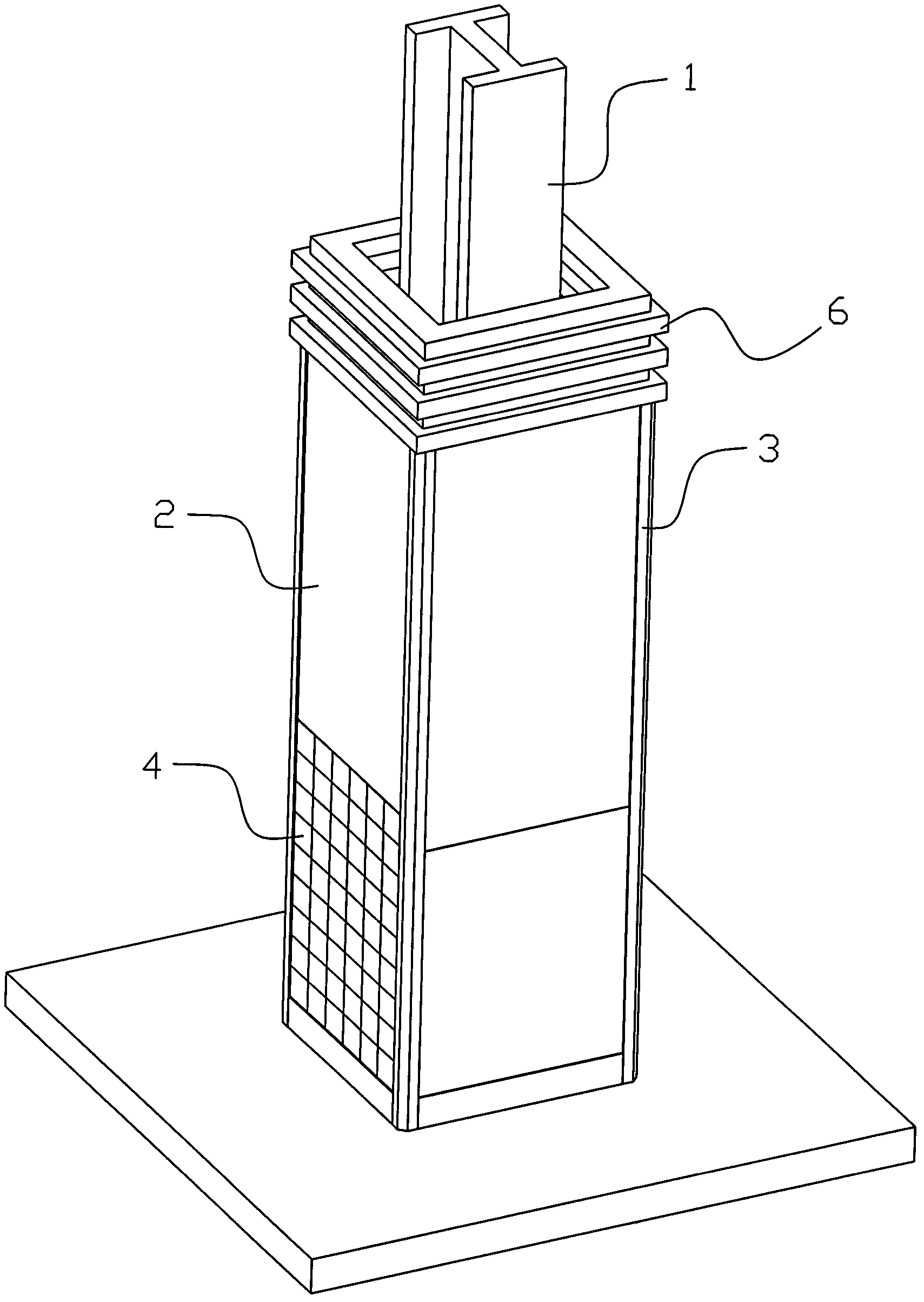

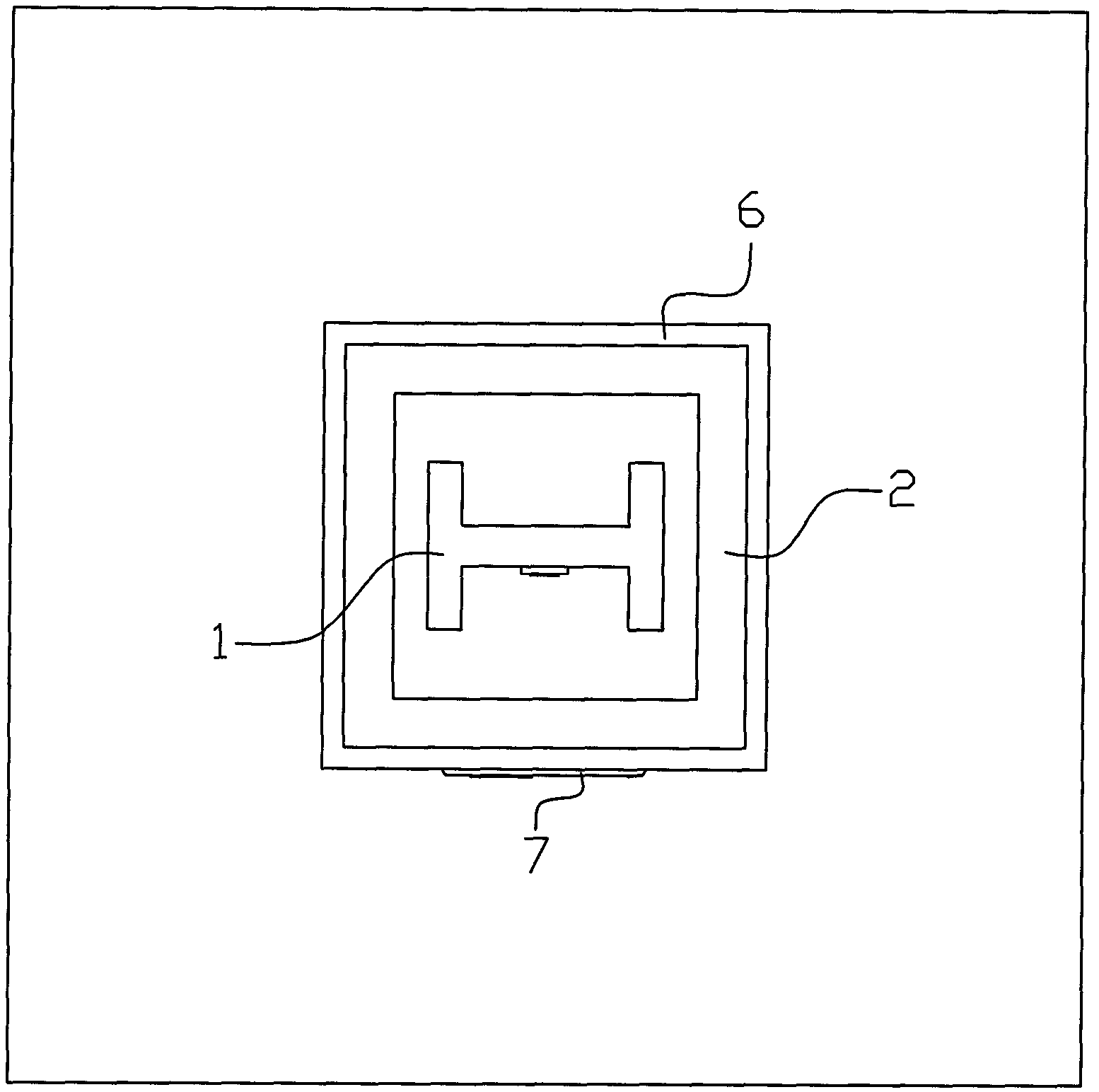

[0022] Such as Figure 1 to 7 As shown, the packaging structure of the column of this embodiment includes a packaging board 2 for wrapping the column 1. The cross section of the packaging board 2 is wrapped in a square shape on the peripheral surface of the lower part of the column 1, and is located on the four edges and corners on the peripheral surface. Cut-off corner-shaped protective plates 3 are embedded vertically in all places to prevent sharp corners from hurting people. The cross section of the protective plate 3 is hexagonal with one side opening 33, and the two sides 32 at the opening 33 of the protective plate 3 are respectively embedded in the notches 20 at the corners, and the packaging plate corresponding to the corners Fix each other together. The two sides of the protective plate 3 are symmetrically embedded in the notches 20 at the corn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com