Heat-preserving wall space finish material

A technology of facing materials and filling materials, applied in covering/lining, construction, building construction, etc., can solve the problems of high consumption of steel, poor thermal insulation performance, poor reliability, etc., to reduce production costs, reduce structural Simple, easy to produce effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

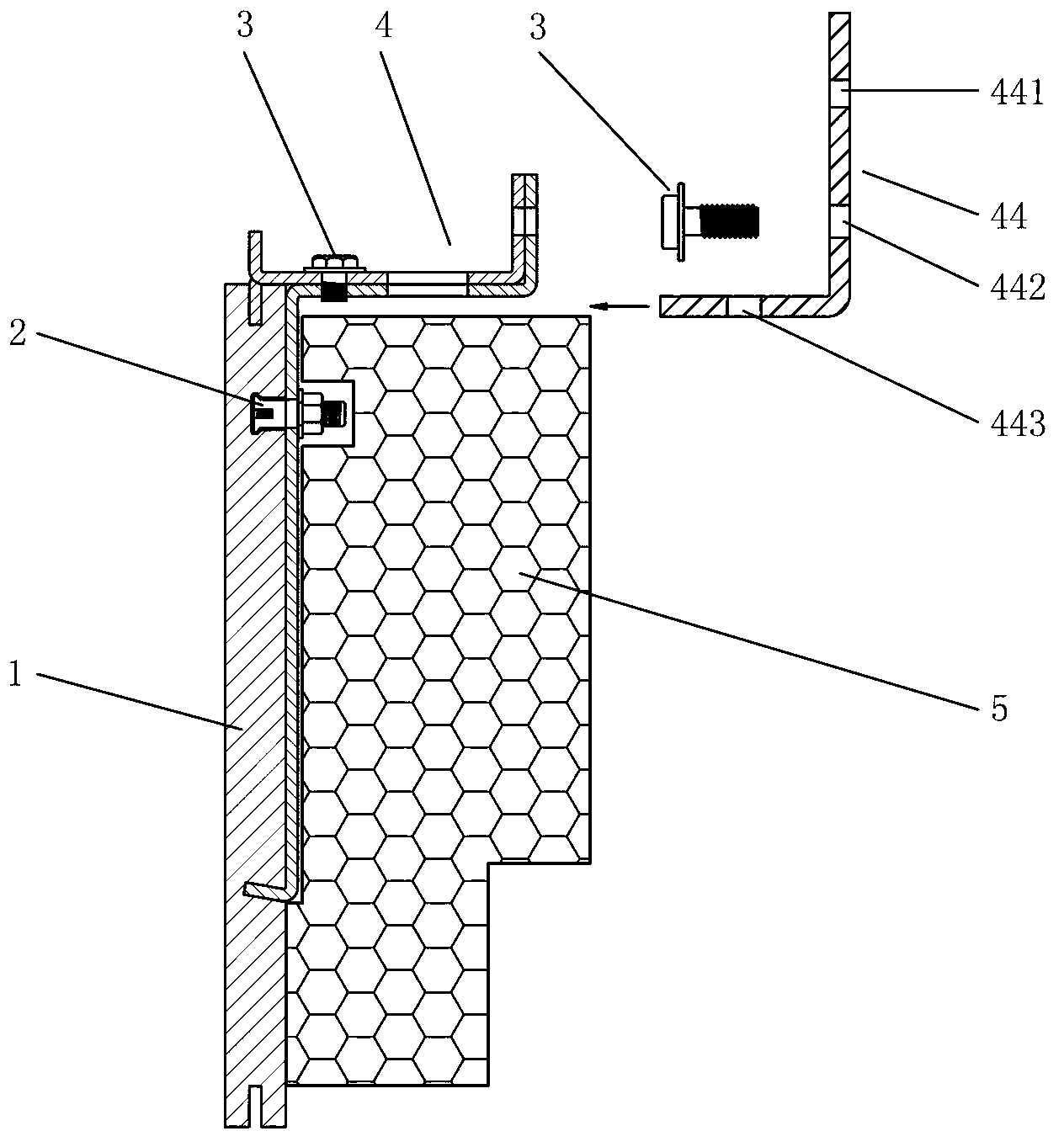

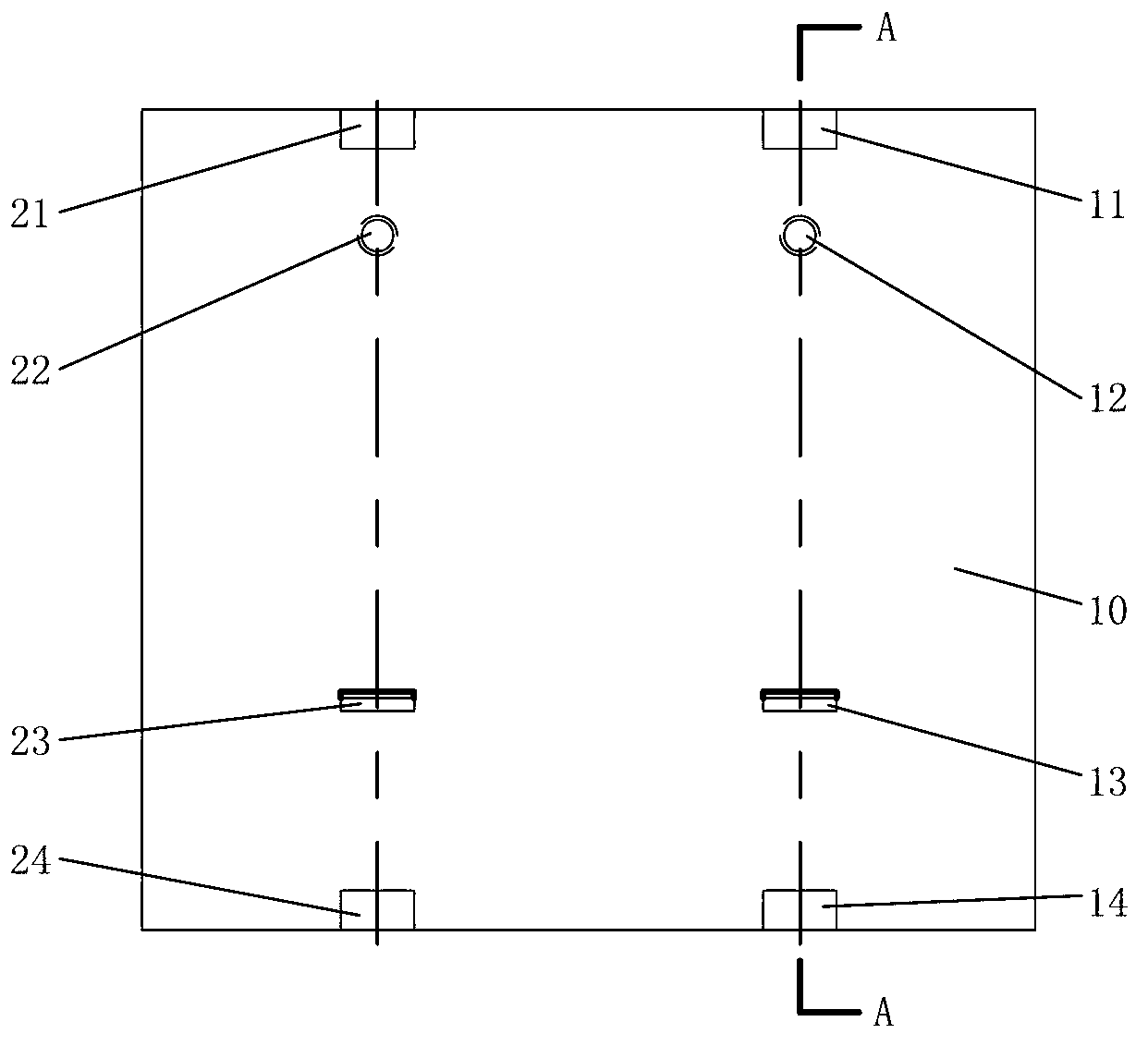

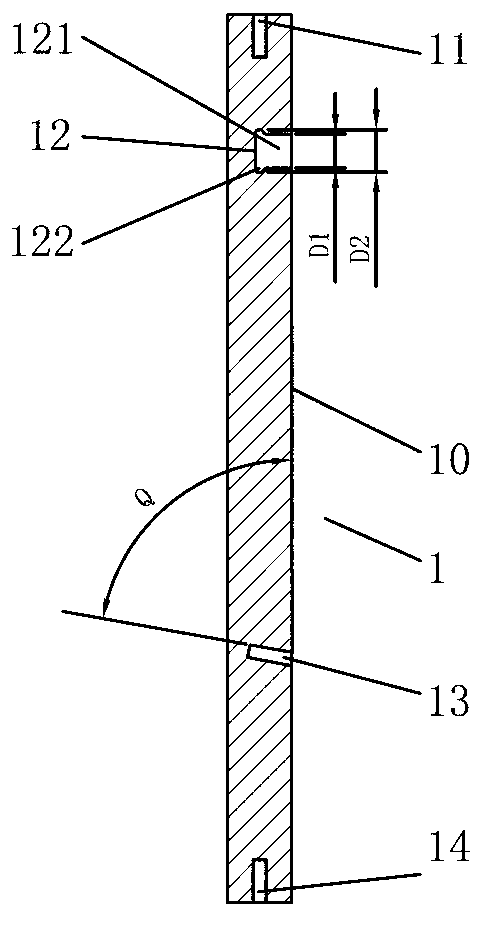

[0031] Example 1, see figure 1 — Figure 5 :

[0032] The thermal insulation wall facing material includes a facing material 1, a pendant 4 and a filling material 5, the back 10 of the facing material 1 is connected with the pendant 4, the back 10 of the facing material 1 and the pendant on the back 10 of the facing material 1 Filling material 5 is formed directly on 4 or is bonded with filling material 5. The pendant 4 includes a pendant 41 fixed on the back of the facing material 1 with a hook 421 and a back bolt 2 and a pendant fixed on the pendant 41. Two 42, hanger one 41 is that the lower end of the bending part 413 is provided with a hook 412 formed by flanging outwards, and the upper end first extends inwards to a horizontal part 414 and then flangs upwards at a right angle to form a vertical connection part 415 with the wall 6 , the middle and upper part of the bent part 413 is provided with a mounting hole 411, the horizontal part 414 of the first pendant 41 is loc...

Embodiment 2

[0041] Example 2, see Figure 6 — Figure 11 :

[0042] The structure of embodiment 2 is basically the same as the mechanism of embodiment 1, the difference is that the above-mentioned hole groups have one or two groups, and each hole group has two back bolt installation blind holes (51 and 54, 61 and 64) and two inclined slots (52 and 53, 62 and 63), and the two back bolt installation blind holes (51 and 54, 61 and 64) of each hole group are provided on the upper and lower sides of the back 10 of the facing material 1, The two inclined slots (52 and 53, 62 and 63) of each hole group are opened between the two back bolt installation blind holes (51 and 54, 61 and 64), and the inclined slots 52 and 62 on the upper side The direction of the chute 53 and 63 on the lower side is directed outward and downward, and a chute 51 and a back bolt installation blind hole 52 on the upper side of each hole group are installed with a pendant 41 (61 and a 62 are installed with another A pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com