Device and method for improving rate of mechanical penetration of directional deflecting section

A technology of deflection and commutator, which is applied in drilling equipment and methods, drilling equipment, earthwork drilling, etc. Arbitrary wellbore build-up rate requirements and the effect of improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

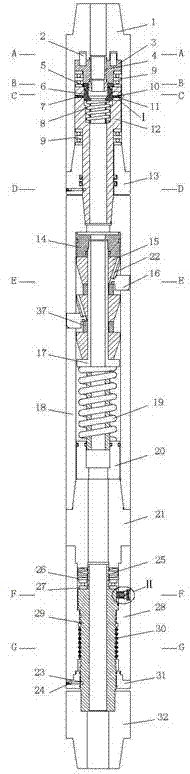

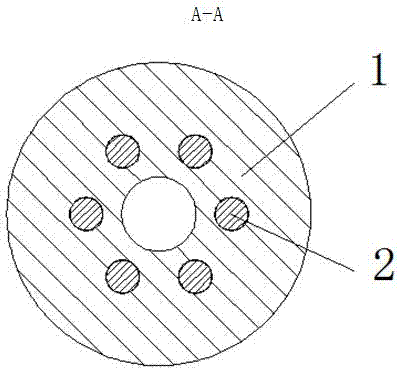

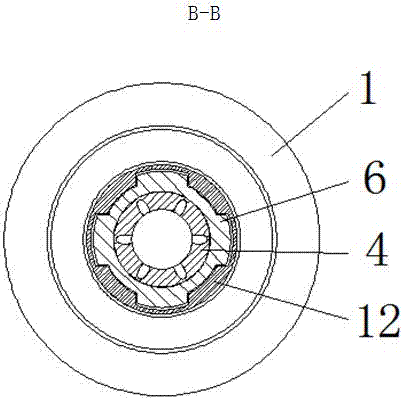

[0019] Depend on figure 1 As shown, the directional deflection and speed-up device involved in the present invention is composed of a torque adjustment nipple, a card arm nipple and a torsion elimination nipple; the torque adjustment nipple includes a torsion nipple housing (1), a cylindrical pin (2), an upload Moving part (3), lower transmission part (12), torque lock part (6), ball seat (4), two-way thrust ball bearing (9), screw pin (5), bayonet pin (11), bayonet hole Plug (10), bayonet spring (7), upper return spring (8), installation joint (13) and installation hole plug (23); cylindrical pin (2) and upper transmission part (3) are installed by interference fit, The remaining exposed section is inserted into the mounting hole of the torque nipple housing (1) corresponding to the cylindrical pin (2); the upper transmission part (3) and the lower transmission part (12) are internal spline structures, and the torque locking part (6) is an external Spline structure and under...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com