Engine inlet fuel temperature regulating system

A temperature regulation and engine technology, applied in the direction of engine components, machine/engine, turbine/propellant fuel delivery system, etc., can solve the problems of consuming the effective power of the aircraft engine, destroying the integrity of the aircraft shape, reducing the performance of the aircraft, etc., to avoid fuel consumption Icing Risk, Advancement of Physics Integration, Effects of Improving Aircraft Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

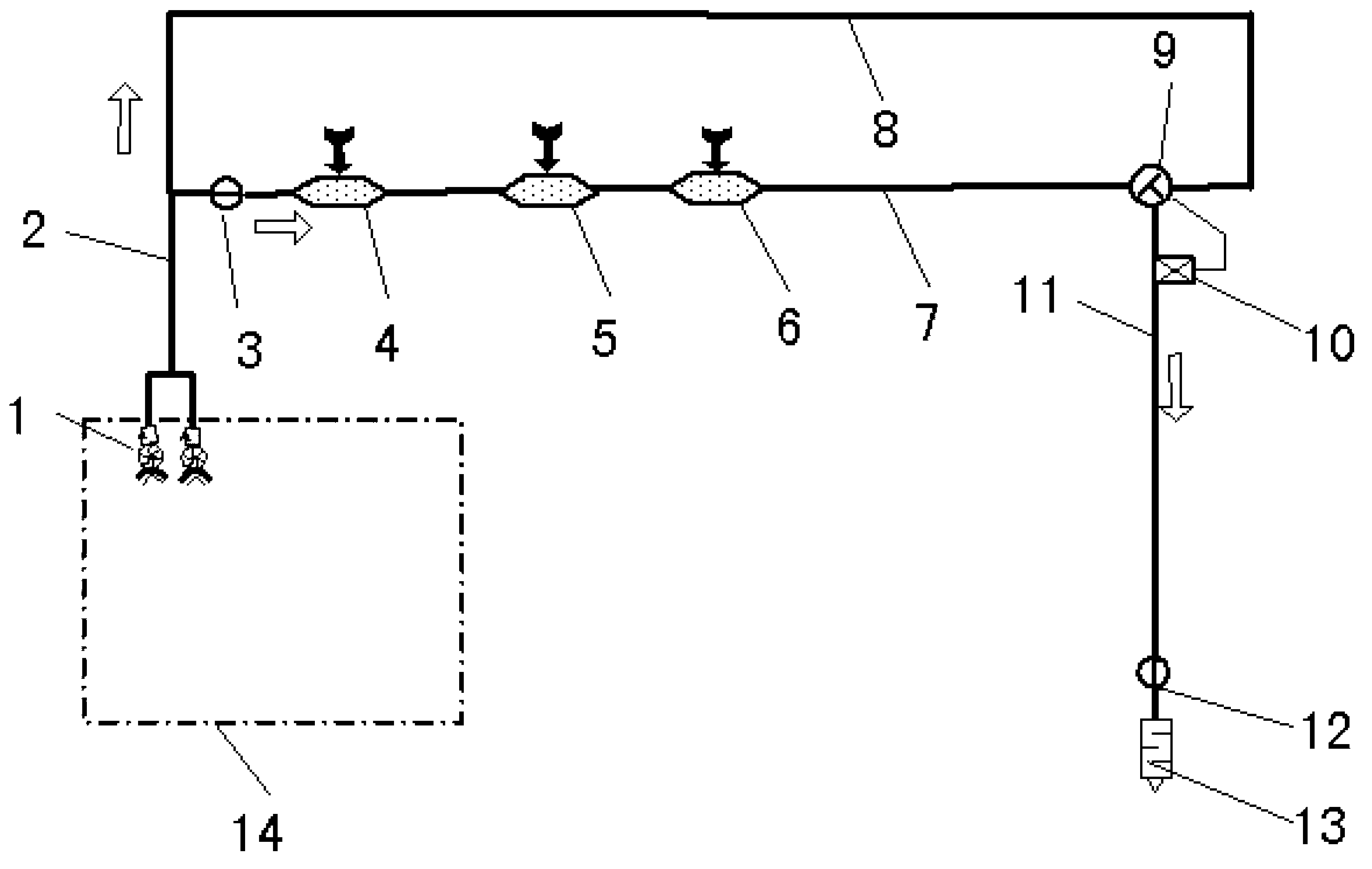

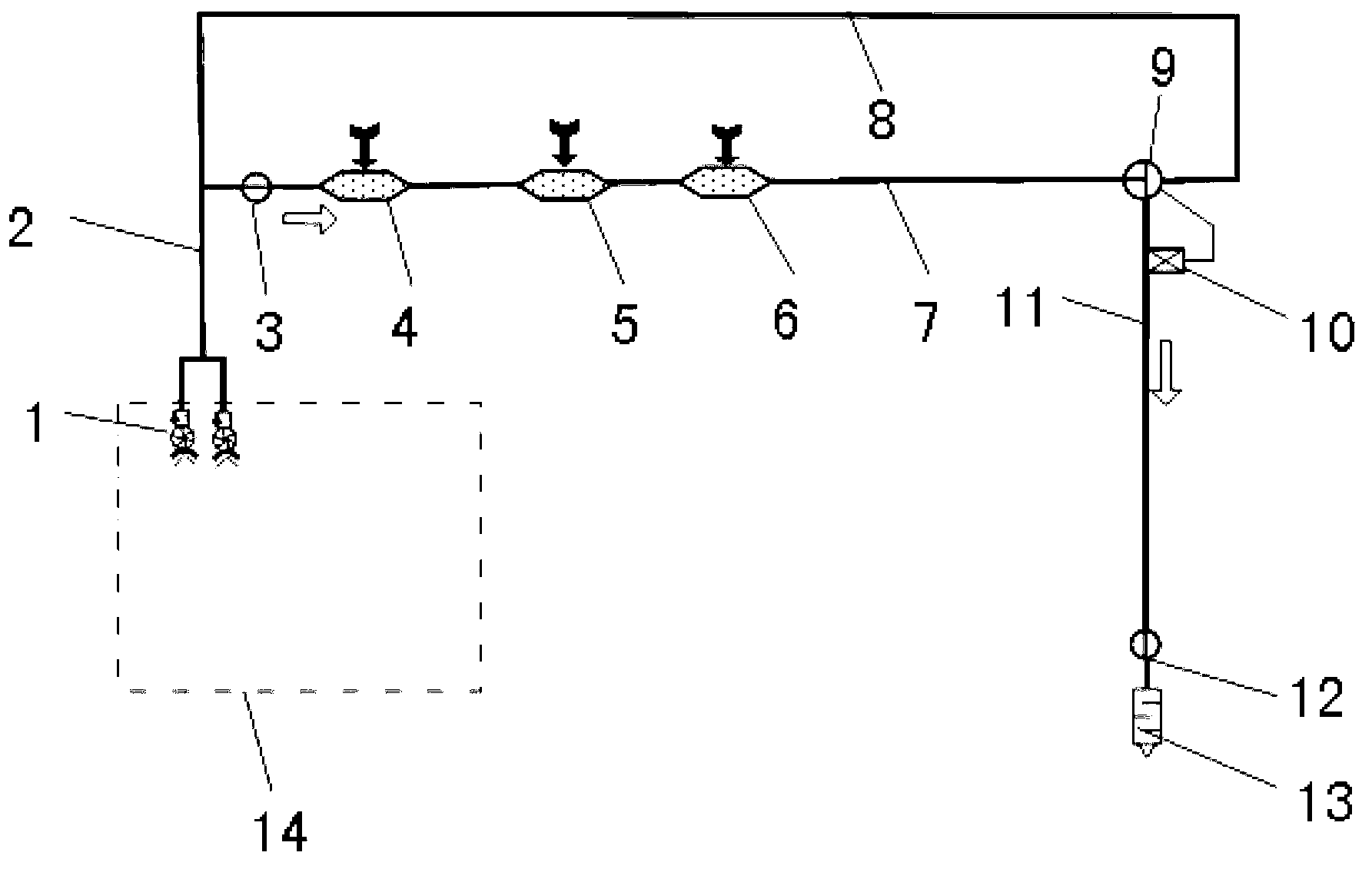

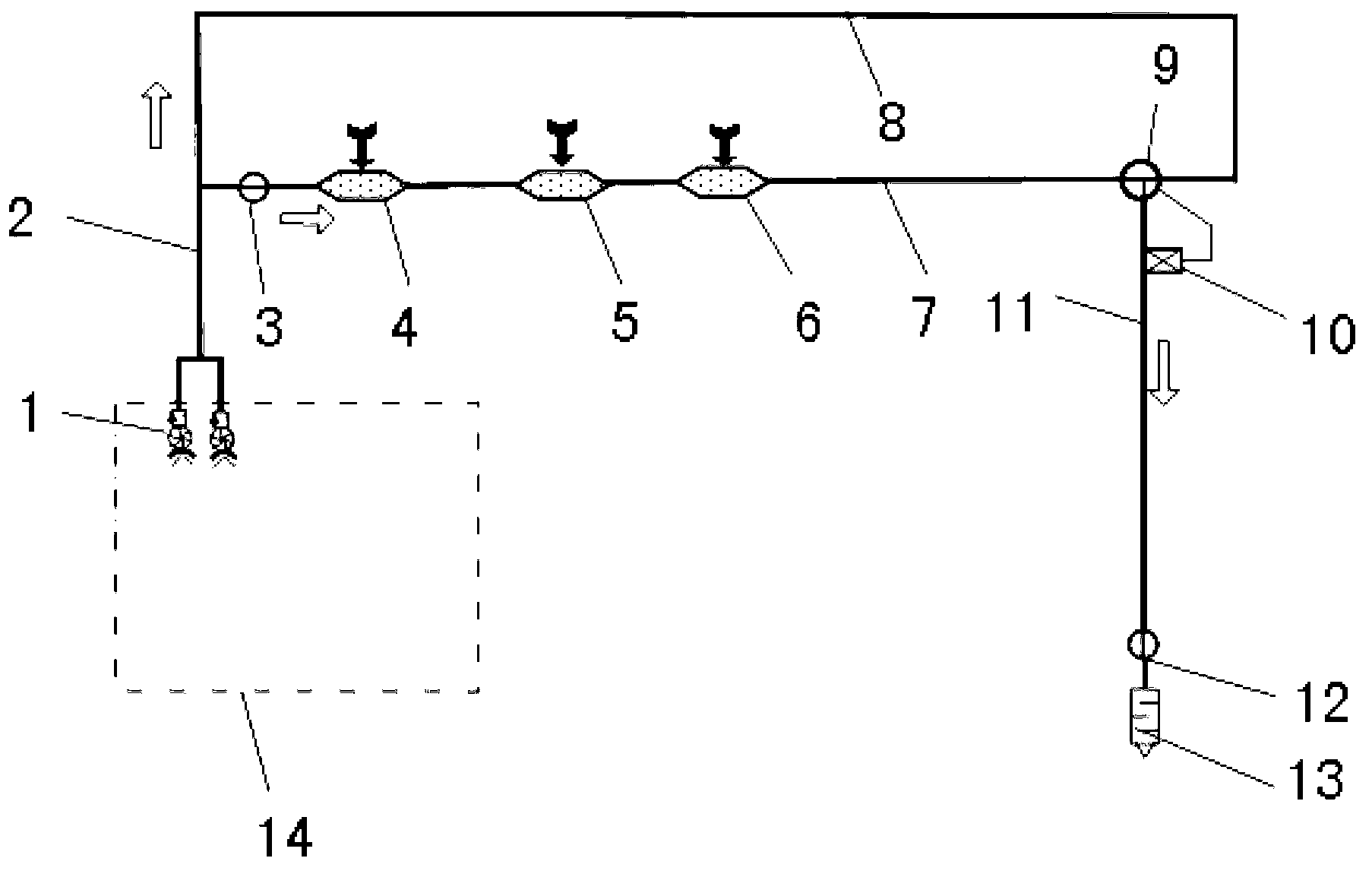

[0013] Below in conjunction with accompanying drawing the present invention is described in further detail, please refer to Figure 1 to Figure 4 .

[0014] Such as figure 1 As shown, a kind of engine inlet fuel temperature regulating system of the present invention, the outlet of two mutual backup oil supply pumps 1 located in the fuel tank 14 communicates with the engine oil supply pipeline 2 and is divided into two paths: heat dissipation path 7 and direct The oil supply circuit 8, the heat dissipation circuit 8 is provided with a cut-off valve 3, and after connecting the environmental control radiator 4, the hydraulic radiator 5 and the inert radiator 6, it merges with the direct oil supply circuit 8 through the three-position solenoid valve 9, and merges A temperature sensor 10 for providing a three-position solenoid valve 9 valve position control signal is installed on the pipeline 11 at the rear, and a fire protection cut-off valve 12 is installed before the entrance o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com