Air suction type threaded pipe air pre-heater and threaded smoke pipe coal economizer combined device

A technology of air preheater and threaded smoke pipe, which is applied in the field of boilers, can solve the problems of easy condensation of flue gas, acid corrosion of air preheater, low heat exchange efficiency, etc., and achieve adjustable blast temperature, Improved service life and high heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

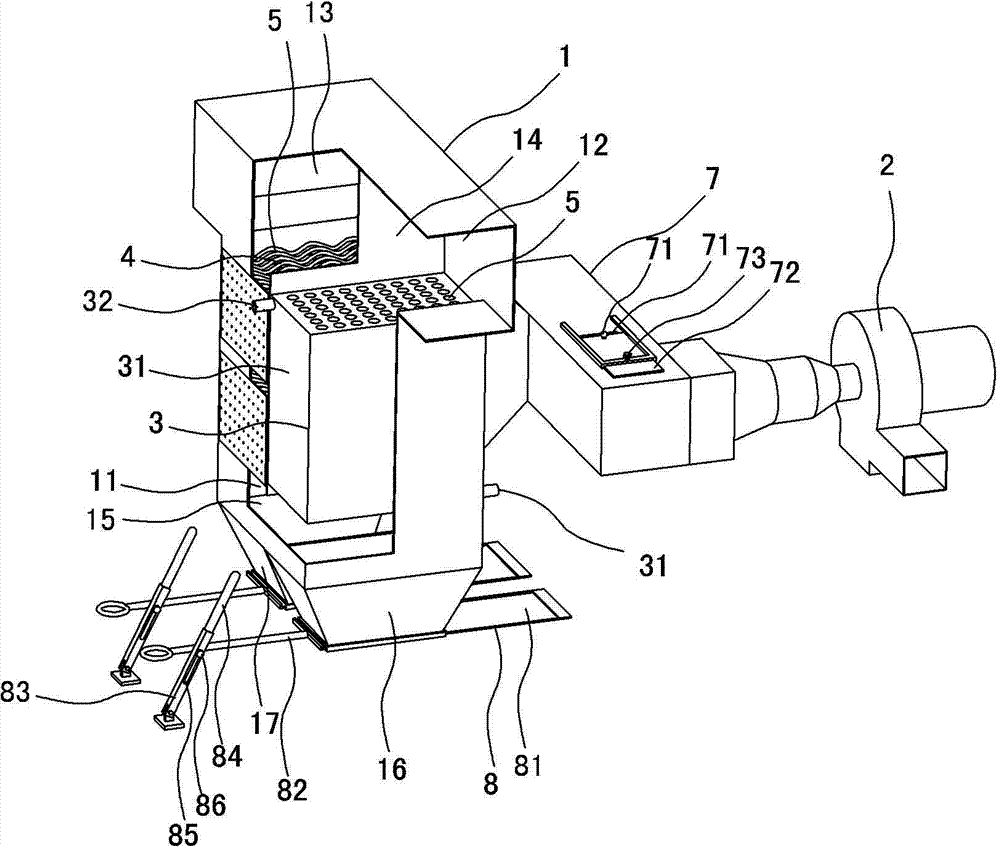

[0010] Such as figure 1 As shown, it includes a shell 1, a blower 2, an economizer 3 and an air preheater 4, and the economizer 3 and the air preheater 4 are installed on the flue gas inlet 12 side and the flue gas passage 11 of the shell 1 respectively. On the side of the flue gas outlet 13, the economizer 3 is composed of a closed water tank shell 33 with a water inlet 31 and a water outlet 32, and a plurality of threaded pipes 5 located inside the water tank shell 33 and penetrating the water tank shell 33 along the flue gas flow direction. The air preheater 4 is composed of a plurality of threaded pipes 5 arranged between the opposite side walls of the housing 1 and passing through the side walls of the housing 1 perpendicular to the flow direction of the flue gas. The air inlet 21 of the blower 2 passes through the air box 7 and the The threaded pipes 5 constituting the air preheater 4 are connected at the nozzles on one side of the housing 1 , and the side wall of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com