Electrostatic dust removal device applicable to high-wet and low-temperature environment

A low-temperature environment, electrostatic dust removal technology, applied in the direction of electrostatic separation, electrostatic effect separation, solid separation, etc., can solve the problems of loss of filtration performance, failure to meet the use requirements, etc., and achieve the effect of reducing short-circuit breakdown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

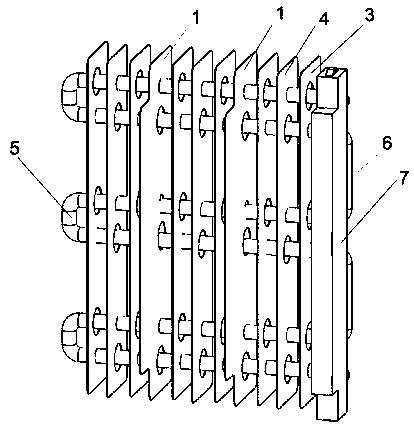

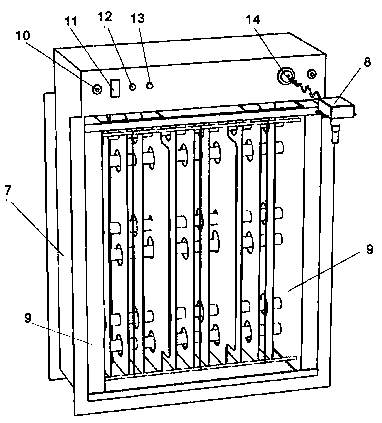

[0021] An electrostatic precipitator suitable for high-humidity and low-temperature environments includes a casing, a dust removal filter element, a grounding electrode plate, and a high-voltage electrode plate, and the dust removal filter element, the grounding electrode plate, and the high-voltage electrode plate are placed in the casing. The housing, dust removal filter element, grounding plate and high-voltage plate of the present invention are all prior art, wherein the grounding plate and high-voltage plate are further divided into the grounding plate 1 of the ionization section, the high-voltage plate 2 of the ionization section, and the dust-collecting plate. Section grounding pole plate 3, dust collecting section high voltage pole plate 4. The difference from the prior art is that the present invention sets a pair of through holes in the upper, middle and lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com