Flue gas treatment system and treatment method

A flue gas treatment system and flue gas treatment technology are applied in the direction of combustion method, combustion product treatment, lighting and heating equipment, etc., which can solve the problems of easy clogging of cloth bags, achieve the effect of not easy to condense and reduce the water vapor content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

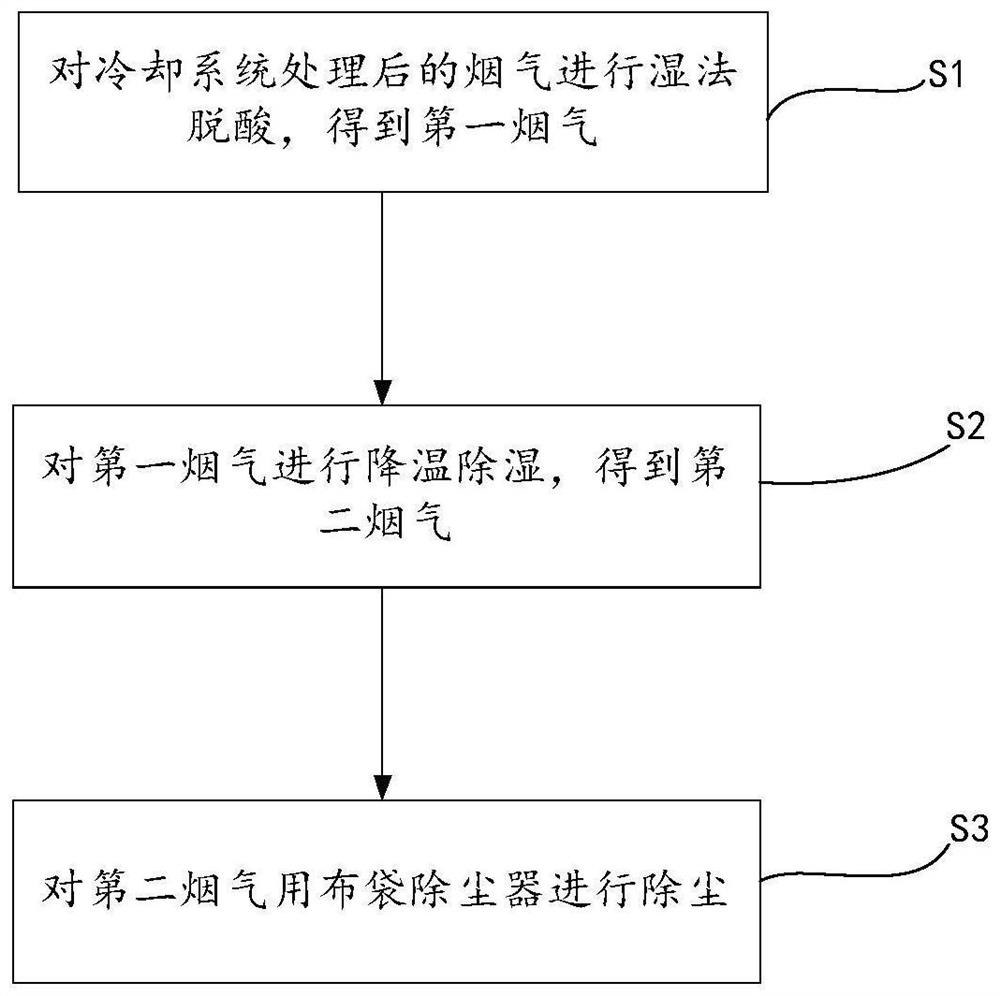

[0047] In order to solve the technical problem of the limitation of using electrostatic precipitator after wet deacidification in traditional incineration system flue gas treatment and the technical problem that bag dust removal is easy to block the bag, the first aspect, the embodiment of the present invention provides a flue gas treatment method, refer to figure 1 shown, including:

[0048] S1. Perform wet deacidification on the flue gas treated by the cooling system to obtain the first flue gas; optionally, the cooling system can be a cooling tower, a heat exchanger or a cooler; preferably, the cooling system is a quenching system;

[0049] S2. Cooling and dehumidifying the first flue gas to obtain the second flue gas;

[0050] S3. Dedusting the second flue gas with a bag filter;

[0051] Wherein, the temperature of the second flue gas is higher than the dew point temperature of the second flue gas, and the temperature of the second flue gas is lower than the maximum servi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com