A method for measuring cable insulation thickness and eccentricity and corresponding measuring device

A technology for measuring cables and measuring devices, used in measuring devices, mechanical measuring devices, and mechanical devices, etc., can solve the problems of inability to carry, large measurement errors, and large measurement limitations, so as to improve stability and accuracy, improve The effect of measuring accuracy and improving measuring speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be noted that the embodiments are illustrative, not restrictive, and cannot limit the protection scope of the present invention.

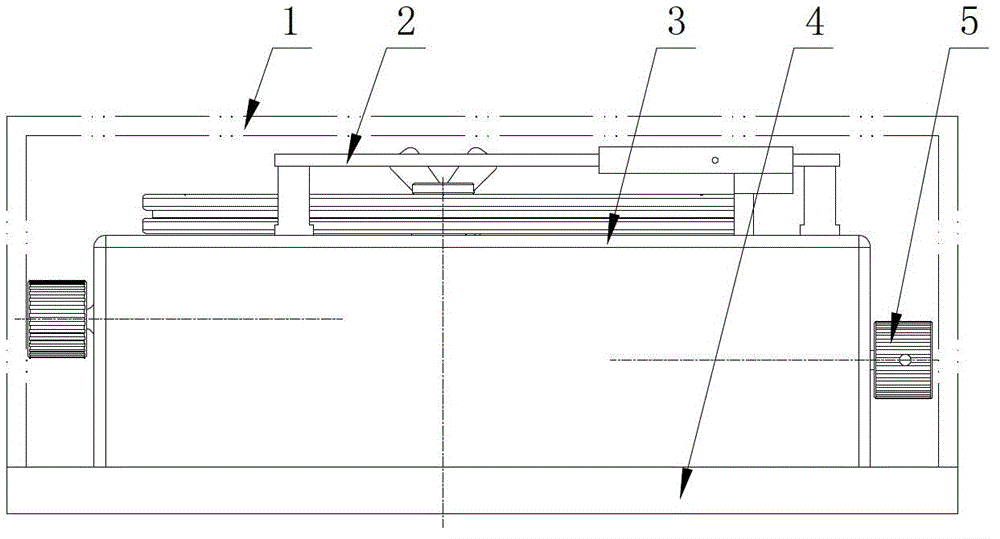

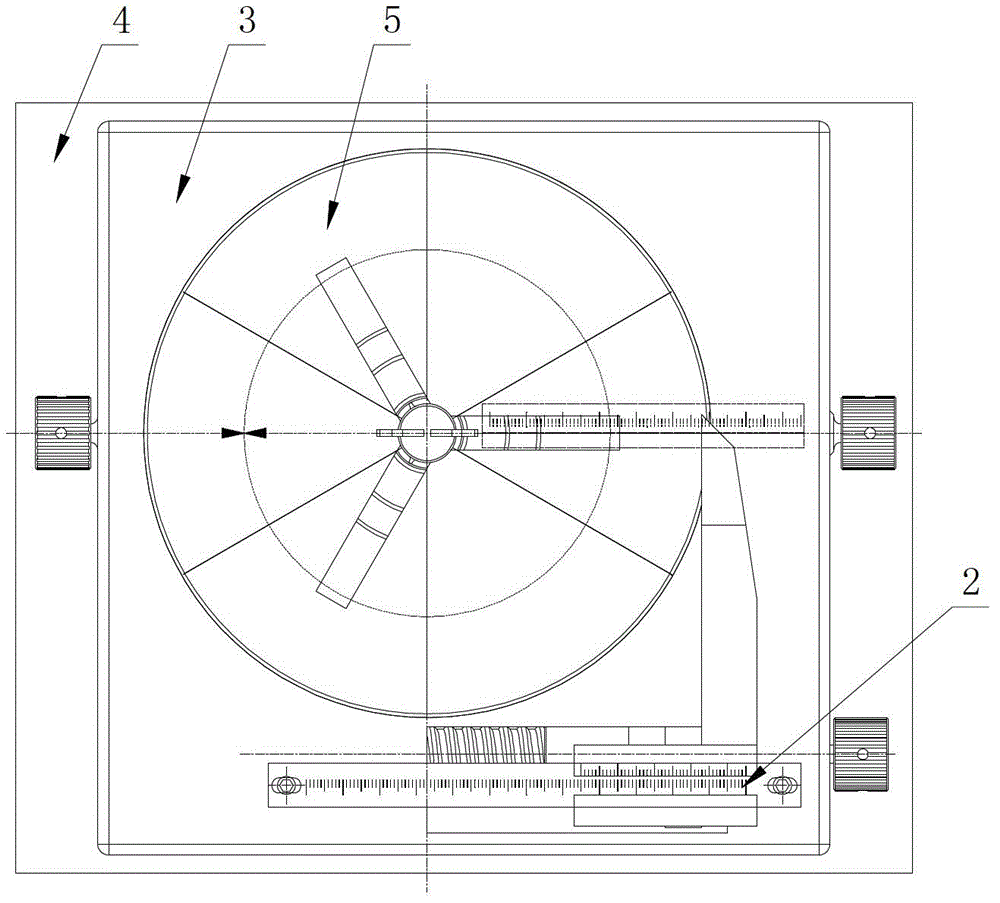

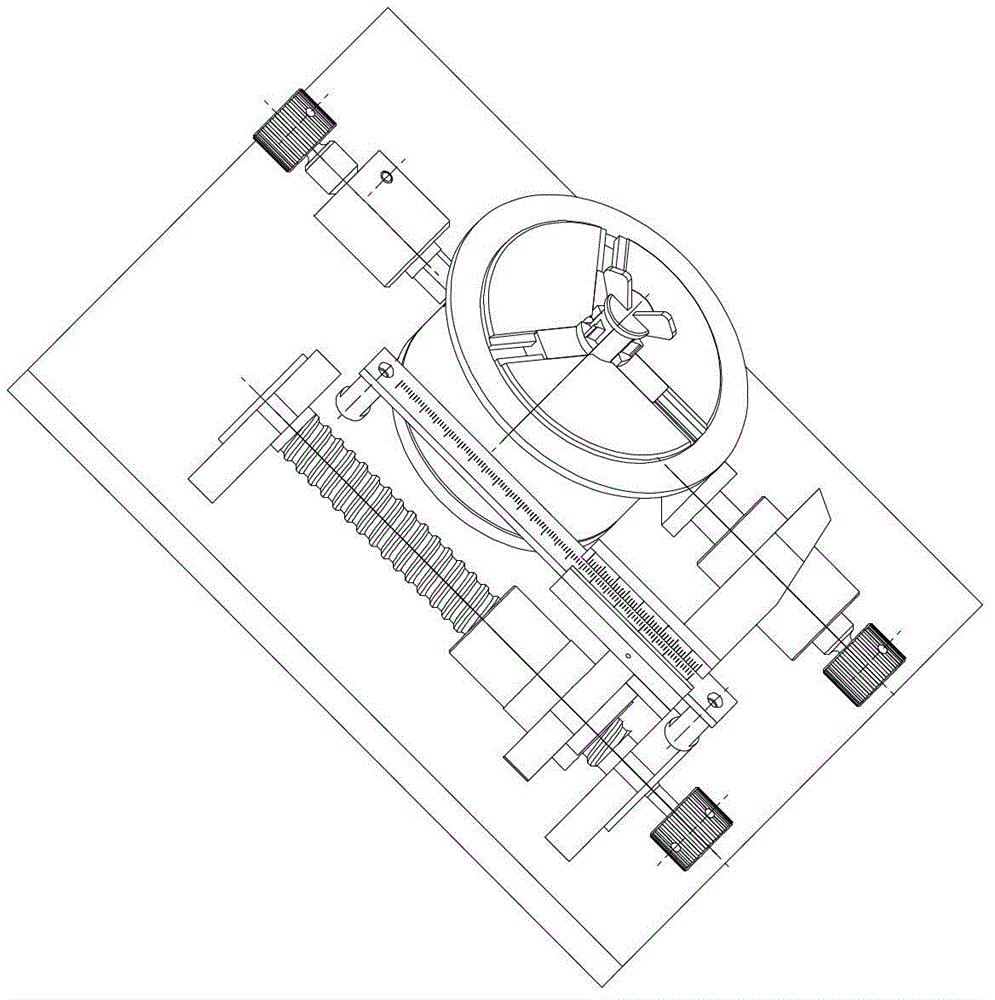

[0049] For ease of understanding, the structure of the portable measuring device for cable measurement used in the cable insulation thickness and eccentricity measurement method is firstly described, which includes a base plate 4, a fixed cover 3, a vernier caliper part 2 and a gear rotation fixed transmission part 5 , the fixed cover is installed on the bottom plate. An outer cover 1 is fastened on the base plate, and the outer cover can cover the fixed cover, the vernier caliper part and the gear rotation fixed transmission part therein. The vernier caliper part and the gear rotation fixed transmission part are described in detail as follows:

[0050] 1. Vernier caliper part

[0051] The vernier caliper part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com