Tensile fixture

A fixture and collet technology, applied in instruments, measuring devices, scientific instruments, etc., can solve the problems of loose fixtures and inability to reliably clamp small samples, and achieve slack compensation, continuous and stable pre-tightening effects, and stable clamping. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

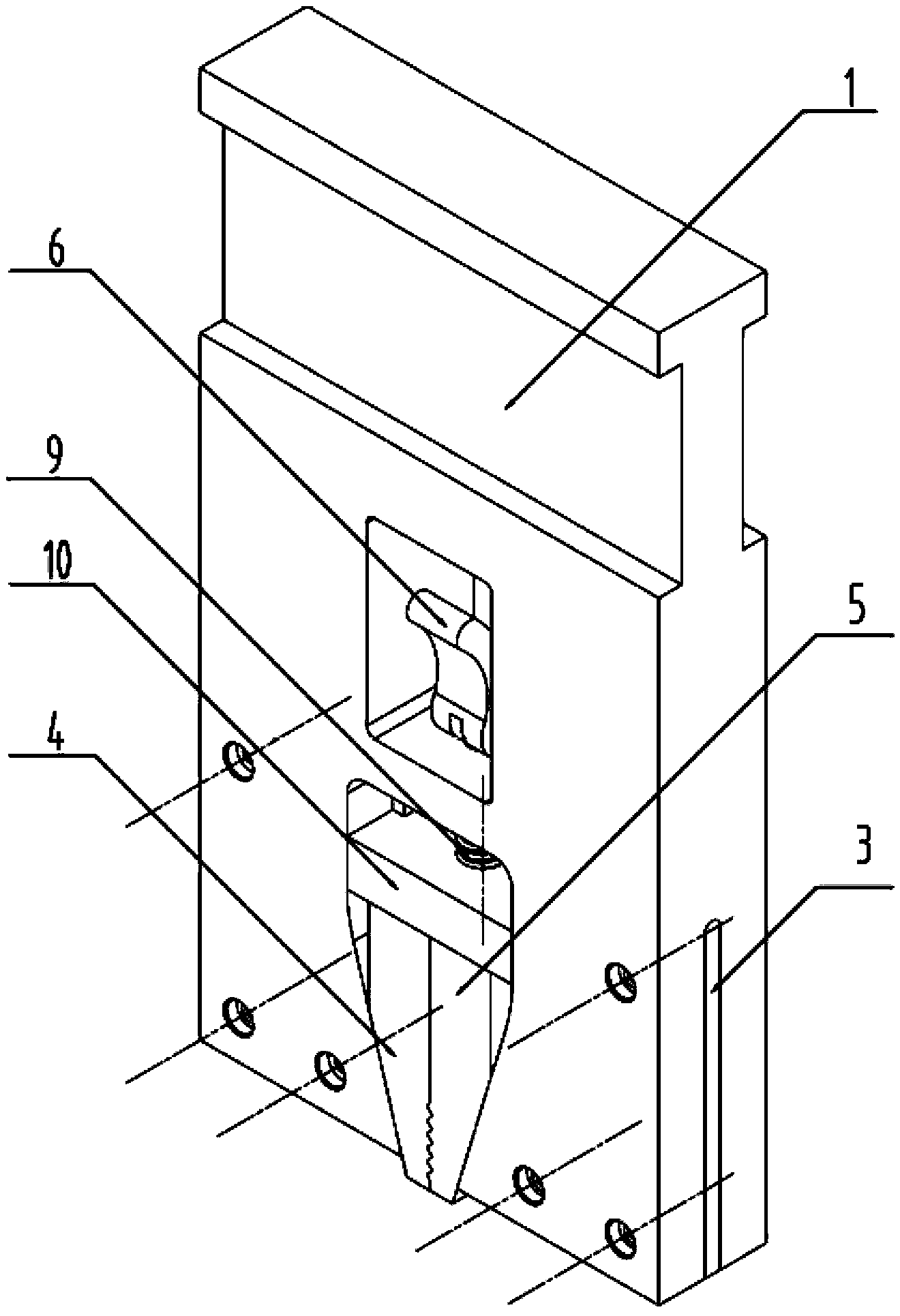

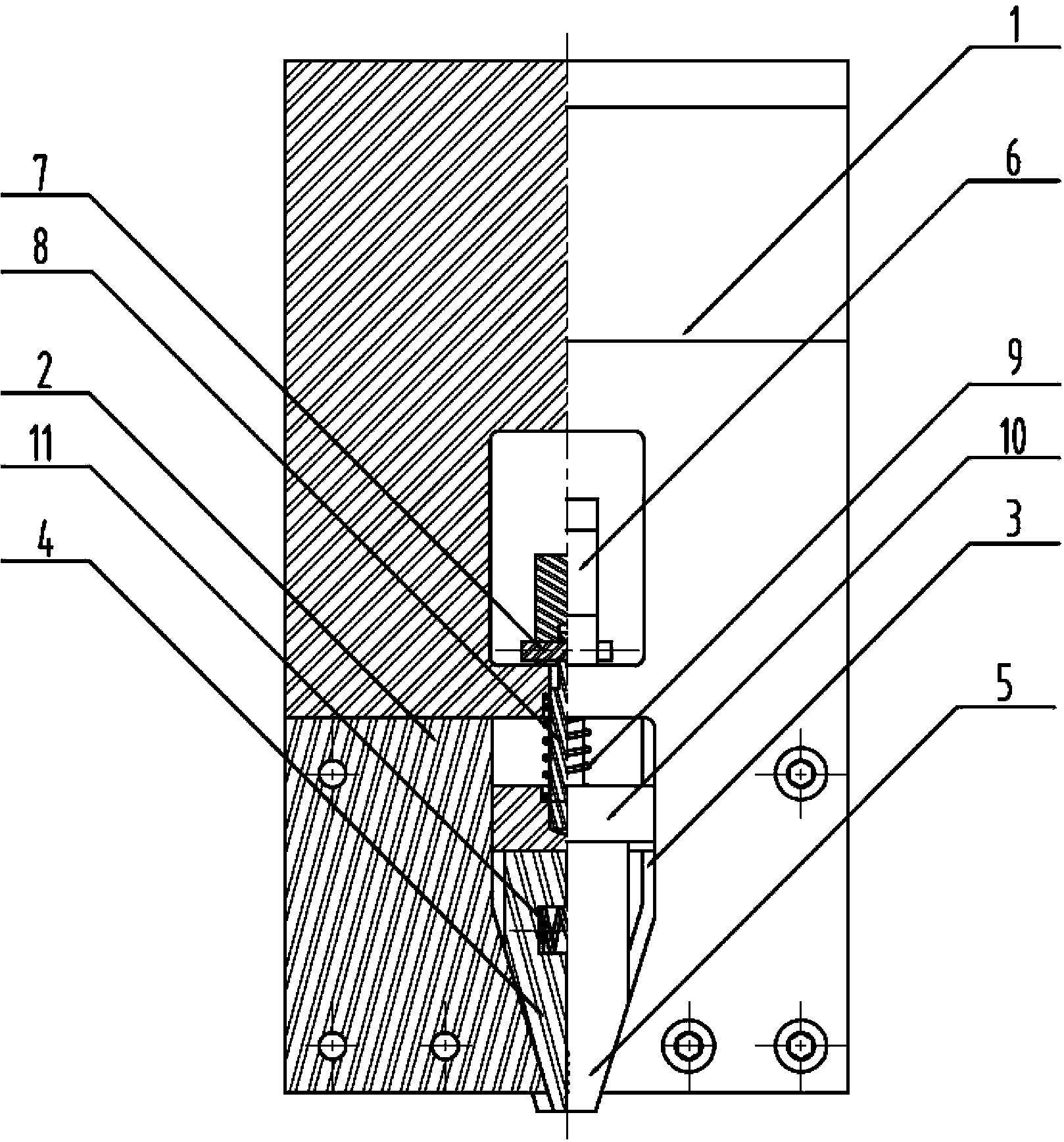

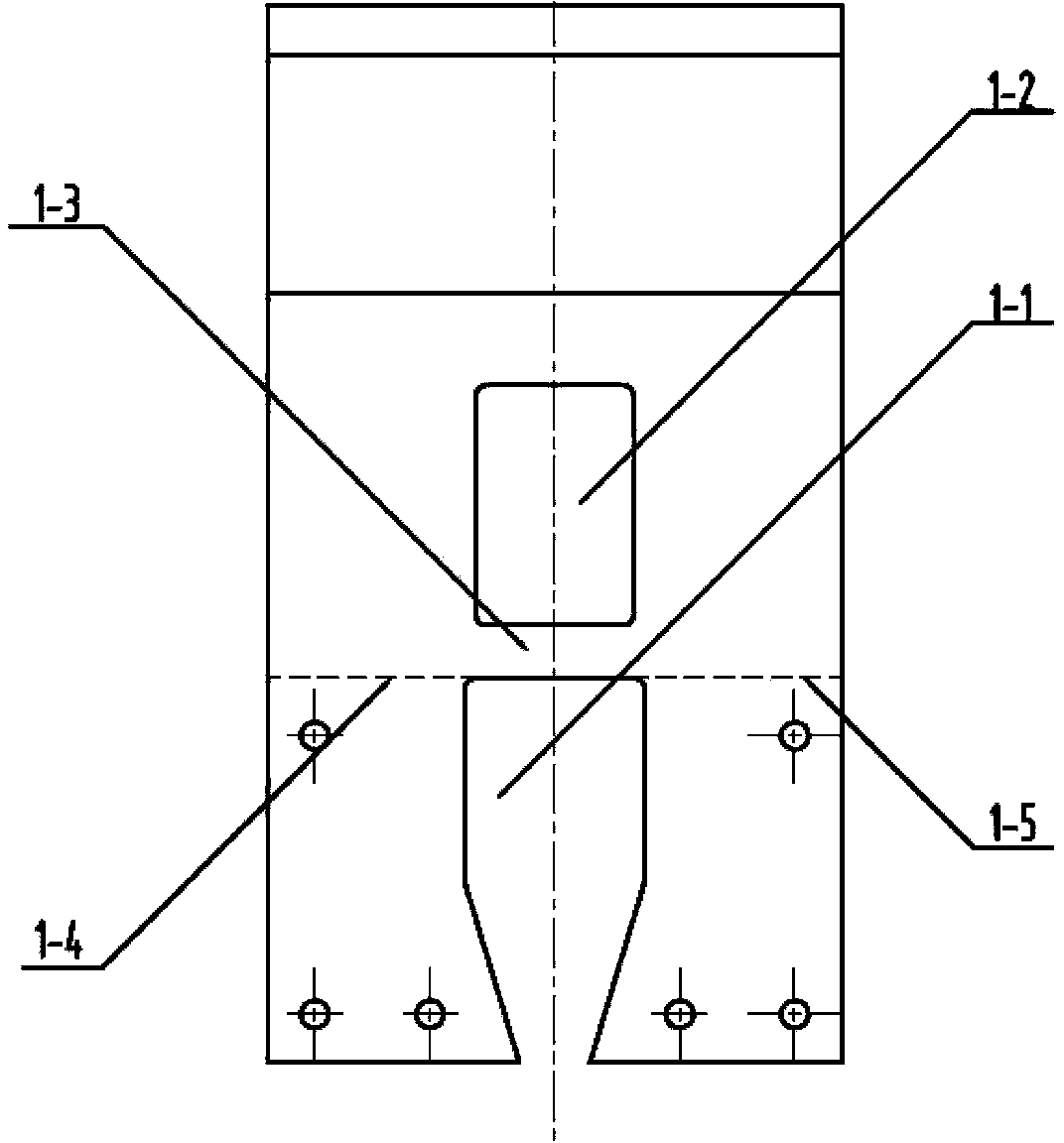

[0028] Such as figure 1 , figure 2 , Fig. 3 (A), shown in Fig. 3 (B), the embodiment of the present invention comprises frame 1, left guide rail 2, right guide rail 3, left chuck 4 and right chuck 5, and described frame 1 bottom has inverted Tapered clamping hole 1-1, the left and right guide rails 2 and 3 are respectively embedded in the left and right side walls of the clamping hole 1-1, and the left chuck 4 and the right chuck 5 are located in the clamping hole, and are respectively connected with The left guide rail 2 and the right guide rail 3 slide fit;

[0029] As shown in Fig. 3 (A) and Fig. 3 (B), the upper part of the frame 1 has a rectangular operating hole 1-2, and there is a partition integrated with the frame 1 between the clamping hole 1-1 and the operating hole 1-2. The plates 1-3 are separated; the left and right sides of the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com