Thin film test sample platform of X-ray diffraction instrument

A technology for testing samples and diffractometers, which is applied in the direction of material analysis using radiation diffraction, etc., can solve the problems of poor versatility of the sample stage, and achieve the effects of improving measurement efficiency, avoiding waste, and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

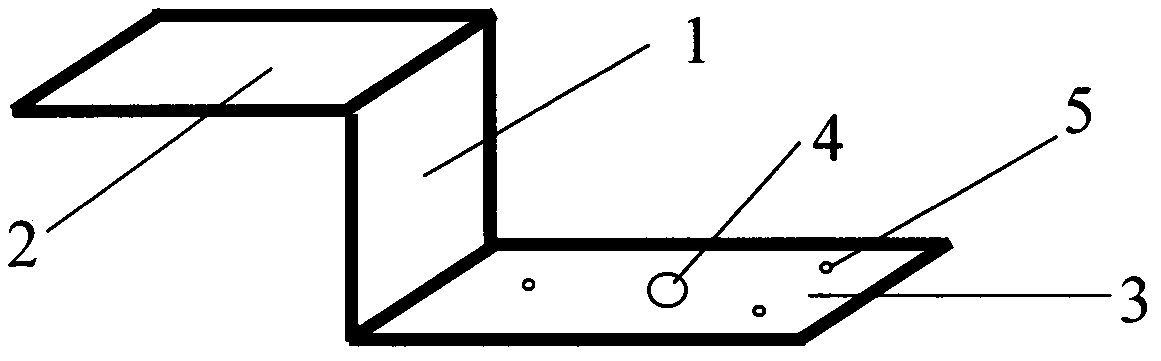

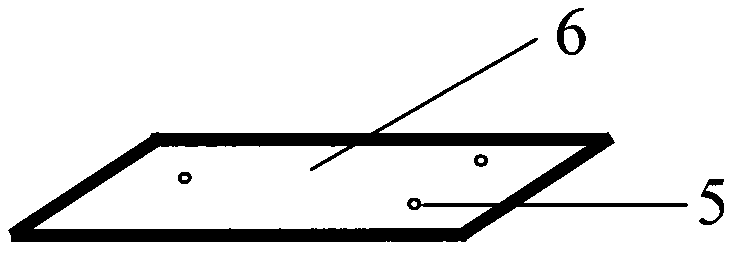

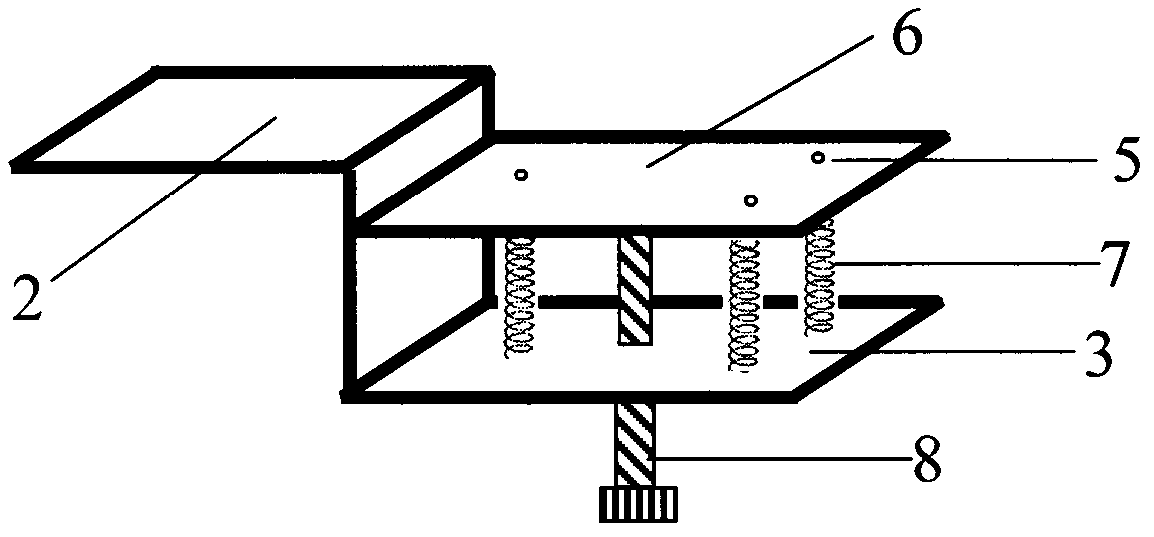

[0015] refer to image 3 First, process a right-angle "Z"-shaped fixed bracket (1), open a screw hole (4) in the center of the lower plate (3), and open three spring hook holes ( 5), three spring hook holes (5) are also opened at the corresponding positions of the flat sample holder (6) and the lower plate (3) of the fixed bracket, and three identical springs (7) are connected to the fixed bracket through the spring hook holes (5). On the bracket (1) and the sample stage (6), the adjusting screw (8) passes through the screw hole (4) on the lower plate of the fixed bracket (1), and contacts with the bottom surface of the sample stage (6), and the adjusting screw (8) , the top sample stage (6) plate is moved to a suitable position, so that the surface of the sample (9) is at the same level as the upper surface of the fixed support (1). Finally, insert the end of the upper plate (2) of the fixed bracket (1) of the sample testing platform into the corresponding position of the X-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com