Optical mixing rod vibration structure for laser illumination speckle reduction

A laser lighting and light mixing rod technology, applied in the field of laser lighting, can solve problems such as energy loss, hindering application, lighting energy loss, etc., achieve efficient lighting shaping, eliminate speckle, and solve the problem between speckle elimination and energy efficiency. contradictory effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

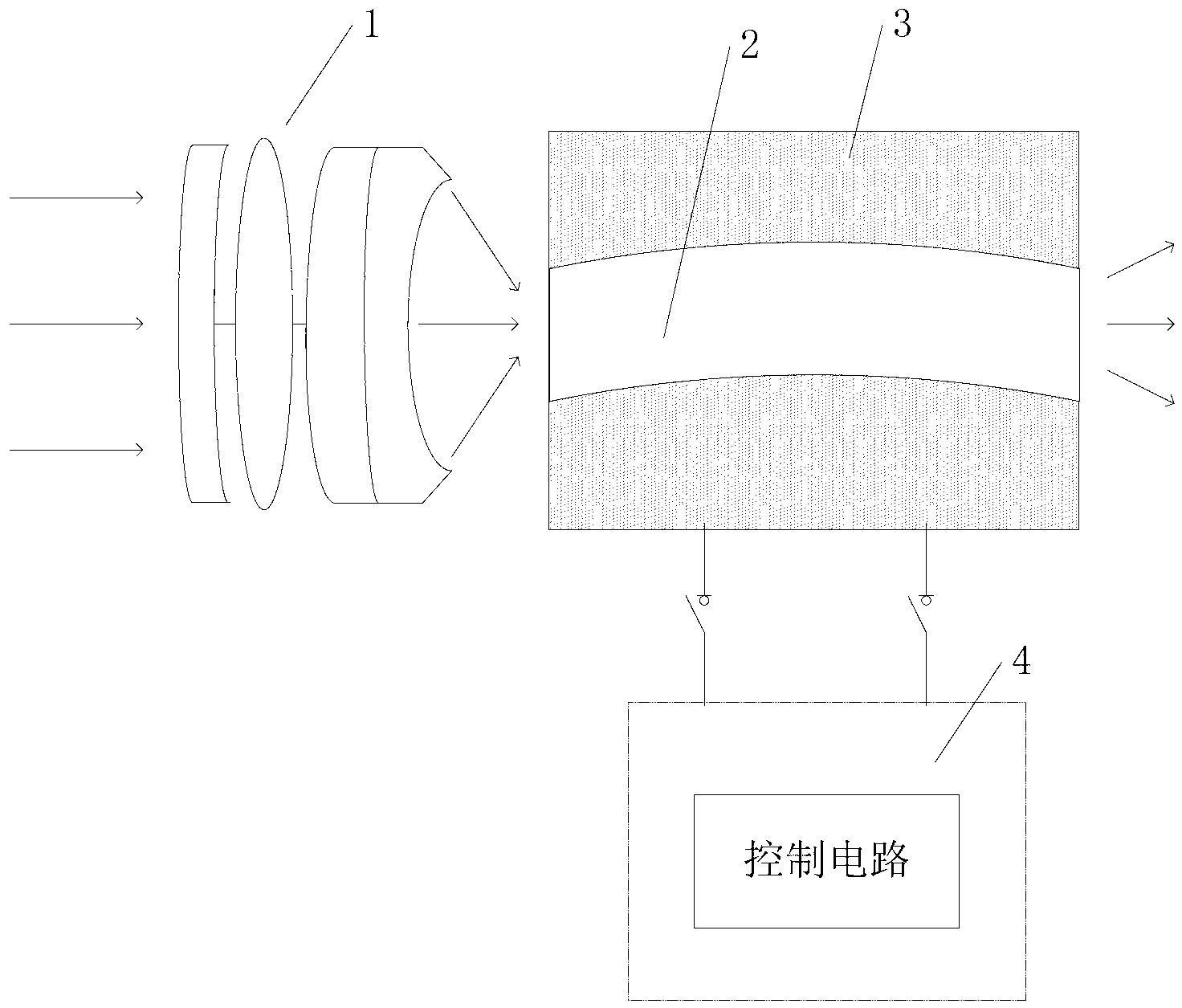

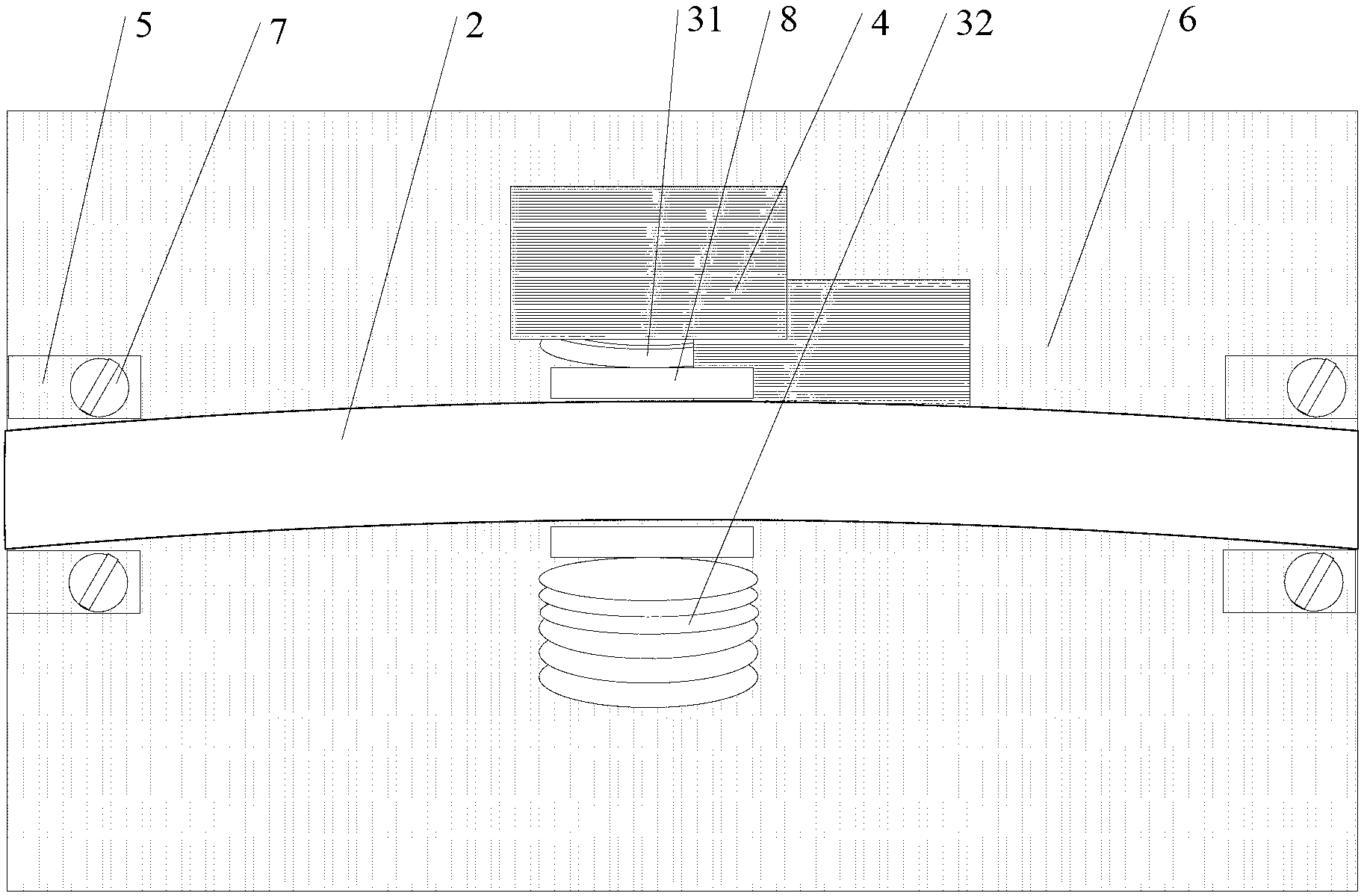

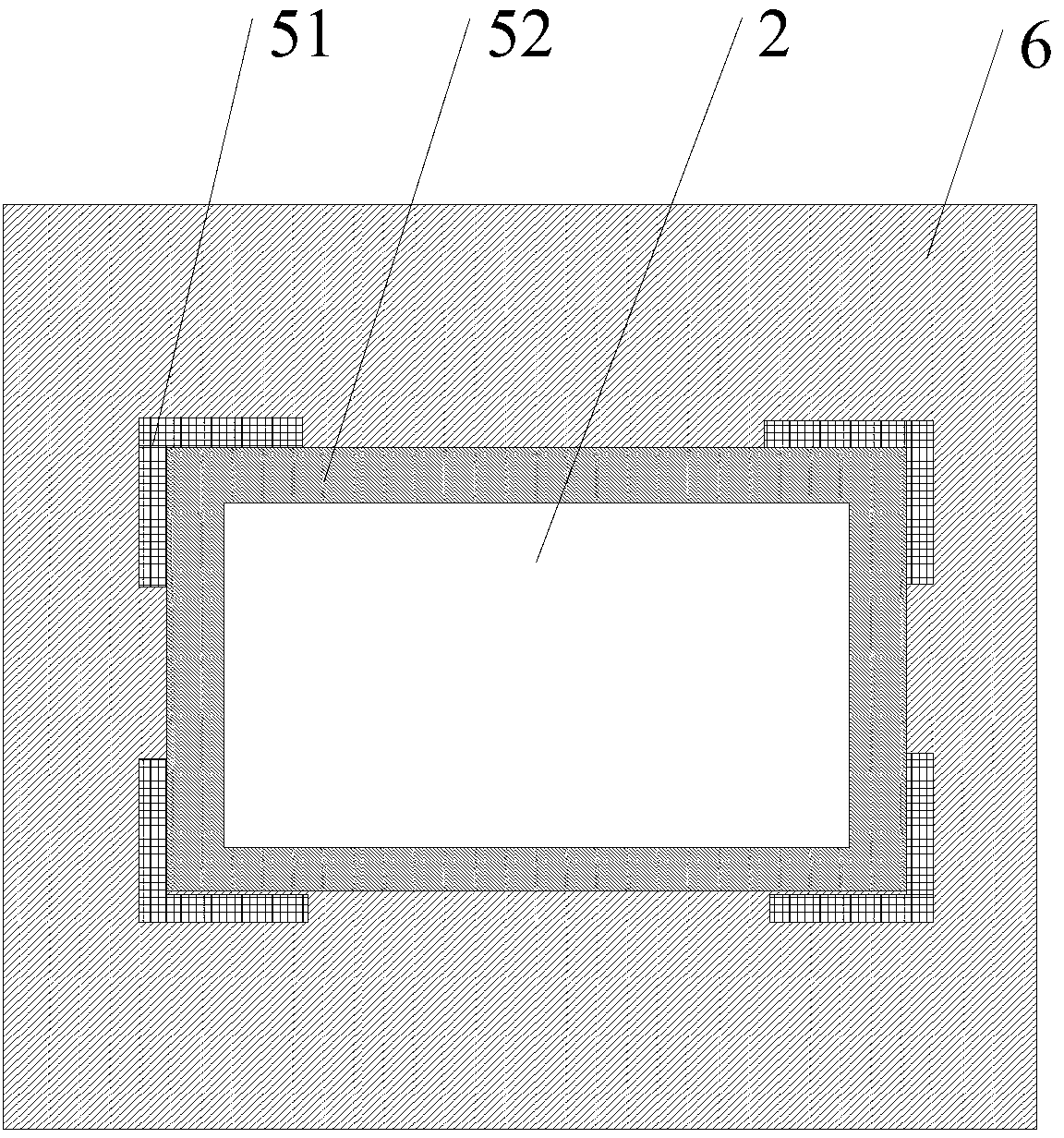

[0025] The invention is a light mixing rod vibration structure used for laser illumination speckle elimination, such as figure 1 As shown, it includes a coupling lens 1 , a light mixing rod 2 , a vibration mechanism 3 and a control circuit 4 .

[0026] The light source emits monochromatic laser light, the laser light enters the coupling lens 1 , the coupling lens 1 converges the laser light emitted by the light source, and outputs it to the incident surface of the light mixing rod 2 .

[0027] The light mixing rod 2 is located in the vibrating mechanism 3, and the vibrating mechanism 3 drives the light mixing rod 2 to vibrate with equal amplitude. In the non-vibrating state, the axis of the light mixing rod 2 coincides with the optical axis of the laser output from the coupling lens 1, and the laser beam passes through the light mixing rod 2 and is o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com