Dual chamber pseudo-capacitor for fuel addition and method for producing same

A technology of adding fuel and pseudocapacitors, which is applied in the field of electrochemistry, can solve the problems of low discharge efficiency and low energy density of single-chamber pseudocapacitors, and achieve the effects of reducing mass transfer resistance, easy recycling and regeneration, and simple treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

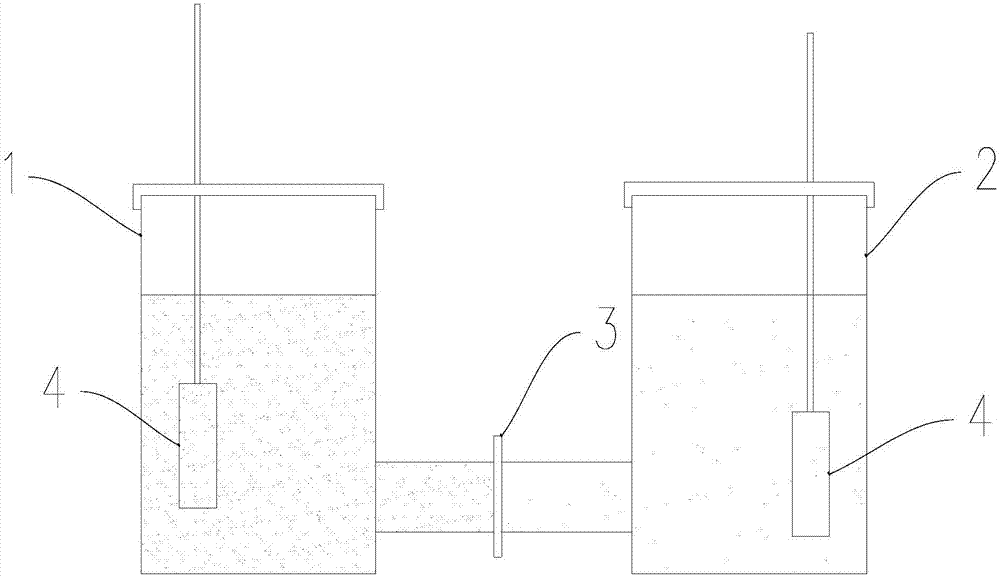

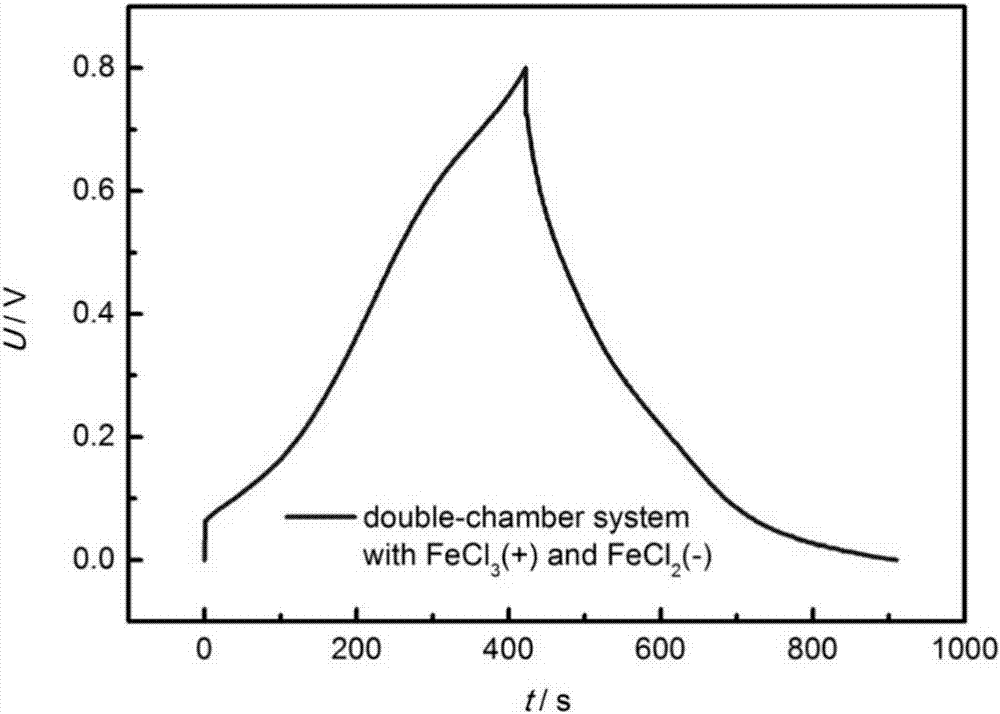

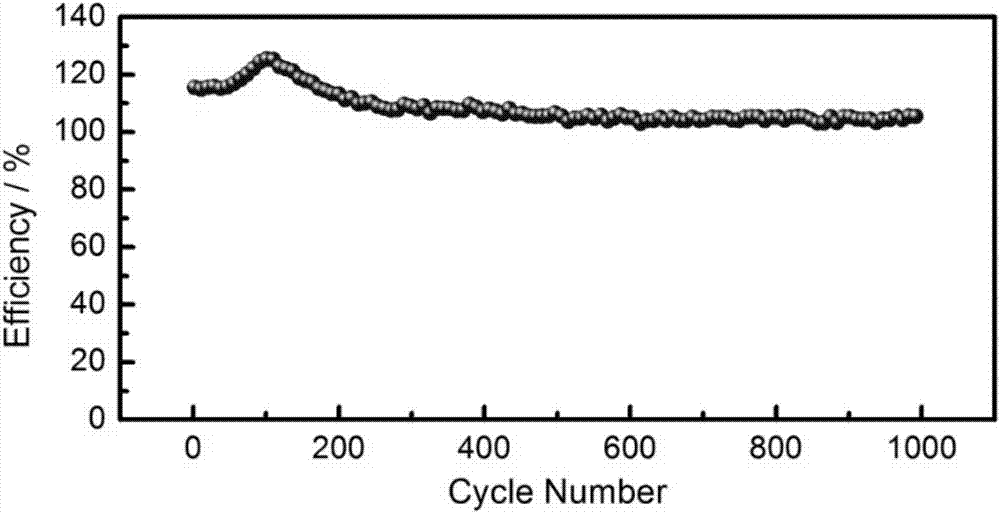

[0042] A preparation method of a fuel-added double-chamber pseudocapacitor, comprising the steps of:

[0043] S1. Prepare aniline and drop it into dilute sulfuric acid to obtain a mixed solution. The concentration of sulfuric acid in the mixed solution is 1-2mol / L, and the concentration of aniline is 0.05-0.25mol / L. Arrange the carbon fibers after degreasing with acetone in the above mixed solution In, the composite material of carbon fiber cloth loaded with conductive polyaniline was prepared by cyclic voltammetry, and the electrode material containing conductive polyaniline was obtained;

[0044] Specifically, the three-electrode cyclic voltammetry electrodeposition method is adopted, carbon fiber cloth is used as the working electrode, the counter electrode is platinum, and the reference electrode is Ag / AgCl; the upper limit potential is 1.2V ~ 1.4V (vs. The potential is 0V~-0.2V (vs.Ag / AgCl); the scanning speed is 10mV / s~100mV / s, and the number of scanning circles is 10~30...

Embodiment 2

[0049] The fuel added to the positive electrode chamber in S2 of Example 1 was changed to copper chloride (the concentration of copper ions in the positive electrode chamber solution after addition was 0.1 mol / L), and the rest of the preparation conditions remained unchanged.

[0050] Carry out constant current charge and discharge test to the dual-chamber pseudocapacitor obtained in this embodiment, the results are shown in Figure 5 , at 2mA / cm 2 Under high discharge current, its discharge specific capacity is as high as 0.90F / cm 2 (214.29F / g), the area energy density is 80.22μWh / cm 2 , the corresponding mass specific energy density is 19.10Wh / kg.

Embodiment 3

[0052] The hydrochloric acid in the S2 of embodiment 1 is changed into the sulfuric acid of 2mol / L, the fuel that positive electrode chamber adds changes copper sulfate (the concentration of copper ion in positive electrode chamber solution after adding is 0.15mol / L), the corresponding negative electrode chamber The ferrous ion concentration of ferrous sulfate is also changed to 0.15mol / L, and all the other preparation conditions are unchanged.

[0053] Carry out constant current charge and discharge test to the dual-chamber pseudocapacitor obtained in this embodiment, at 2mA / cm 2 Under the high discharge current, its discharge specific capacity is as high as 1.32F / cm 2 (314.29F / g), the area energy density is 117.66μWh / cm 2 , the corresponding mass specific energy density is 28.01Wh / kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com