A preparation method of mems supercapacitor with controllable dielectric film thickness

A technology for supercapacitors and dielectric films, which is applied in the manufacture of hybrid/electric double layer capacitors, the manufacture of microstructure devices, and the process for producing decorative surface effects, etc. It can solve the problems of uniform deposition of dielectric films, complex processes, and high costs. problem, to achieve the effect of controllable dielectric film thickness, simple process and controllable thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

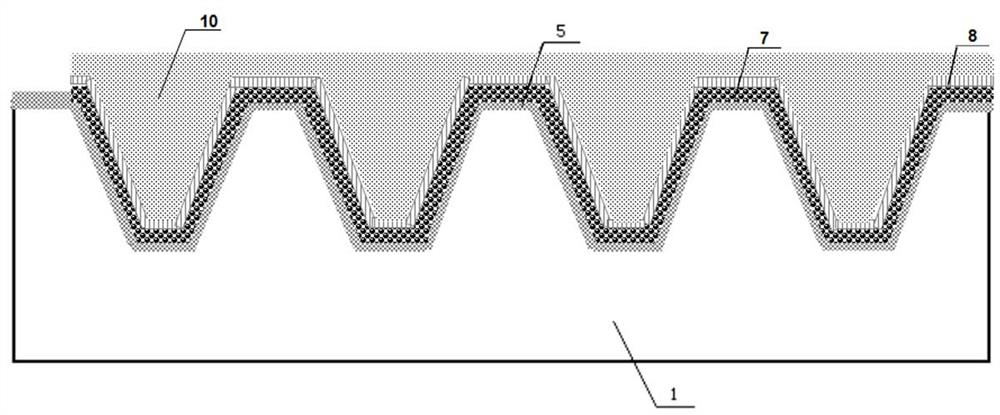

[0030] The MEMS electrostatic supercapacitor includes a silicon wafer 1, a three-dimensional groove array structure 4 is etched on the silicon wafer, an aluminum layer is sputtered on the etched silicon wafer as the lower electrode layer 5, and an anode is passed on the substrate of the sputtered aluminum layer. The oxidation method directly forms the aluminum oxide dielectric film layer 7, and then sputters the metal gold layer on the dielectric film layer 7 as the upper electrode layer 8, and the lower electrode layer 5 is partially exposed to the upper electrode layer 8, and the large specific surface area three-dimensional groove array structure 4 There is a filling layer 10 in the groove.

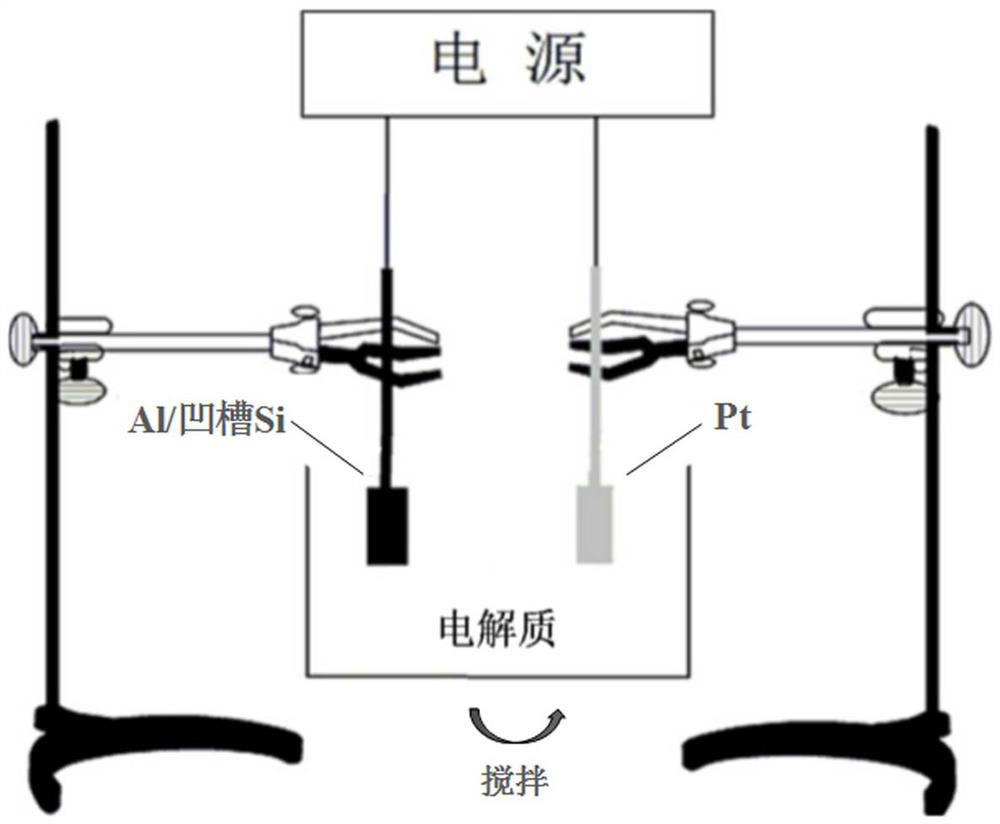

[0031] A method for preparing a MEMS supercapacitor with a controllable dielectric film thickness, comprising the steps of:

[0032] 1. Select a 4-inch silicon wafer 1 as the substrate, and wash the silicon wafer 1 in xylene, acetone, alcohol, sulfuric acid / hydrogen peroxide, ammonia / h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com