Coating method of electrode material and coating thereof, and application of electrode material

An electrode material and coating technology, which is applied to the coating method of electrode materials and its coating and application fields, can solve the problems of increasing the cost of lithium-ion batteries, poor material cycle stability, poor conductivity, etc., and achieve improved surface interface structure Stability, reduce design and R&D costs, and facilitate the effect of industrialized mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A method for coating an electrode with a composite material, comprising the following steps:

[0047] (1) First prepare the ethanol solution slurry of silicon nanoparticles and carbon nanotubes (mass ratio 9:1), load it evenly on the copper foil, and obtain a silicon loading per unit area of 1 mg / cm after drying. 2 electrode pads;

[0048] (2) The 10cm 2 Put the electrode sheet into a solution of tetrahydrofuran (20ml) and triethylamine (2ml) containing 2mg of compound 1, react at 40°C for 10 hours, and take out the electrode sheet;

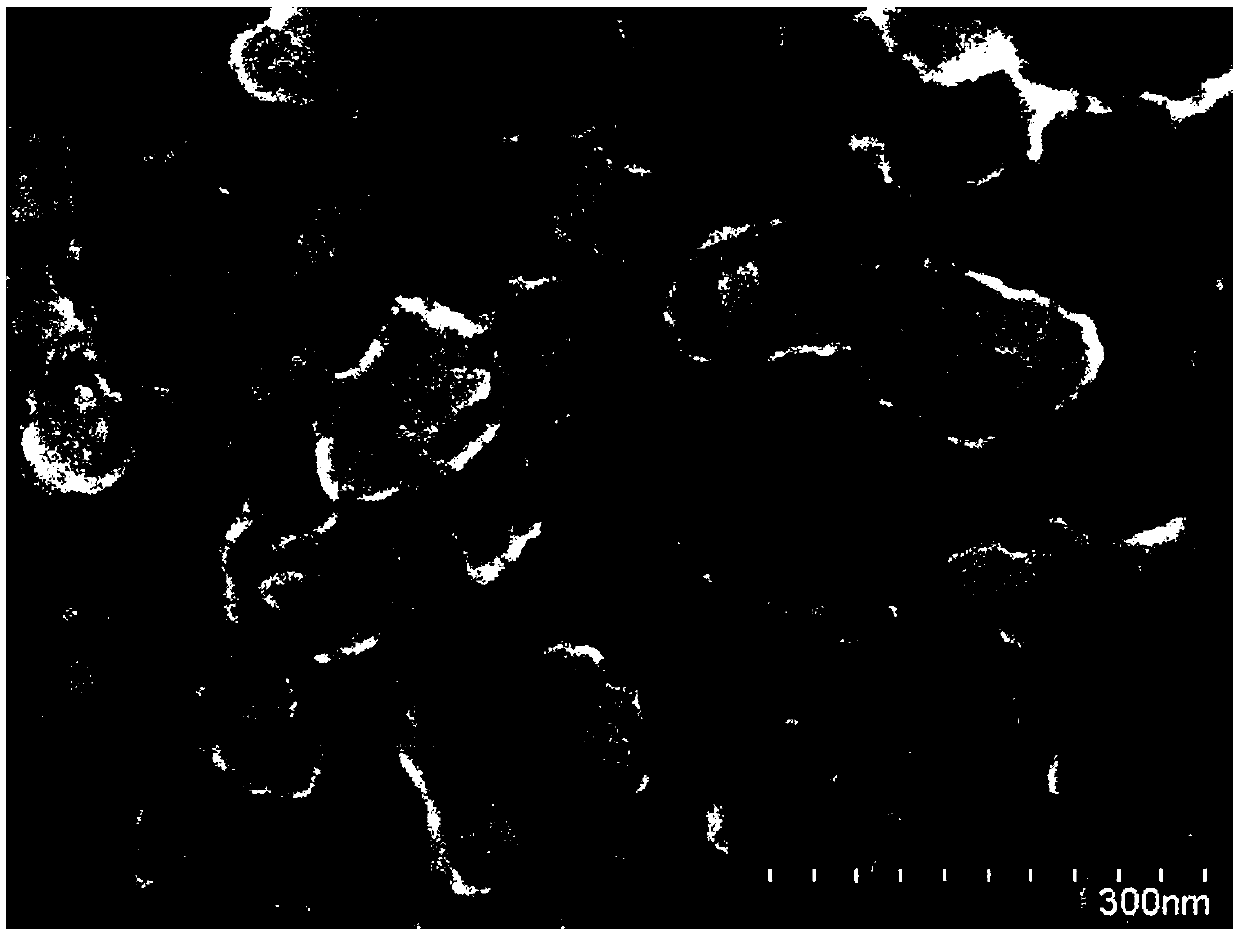

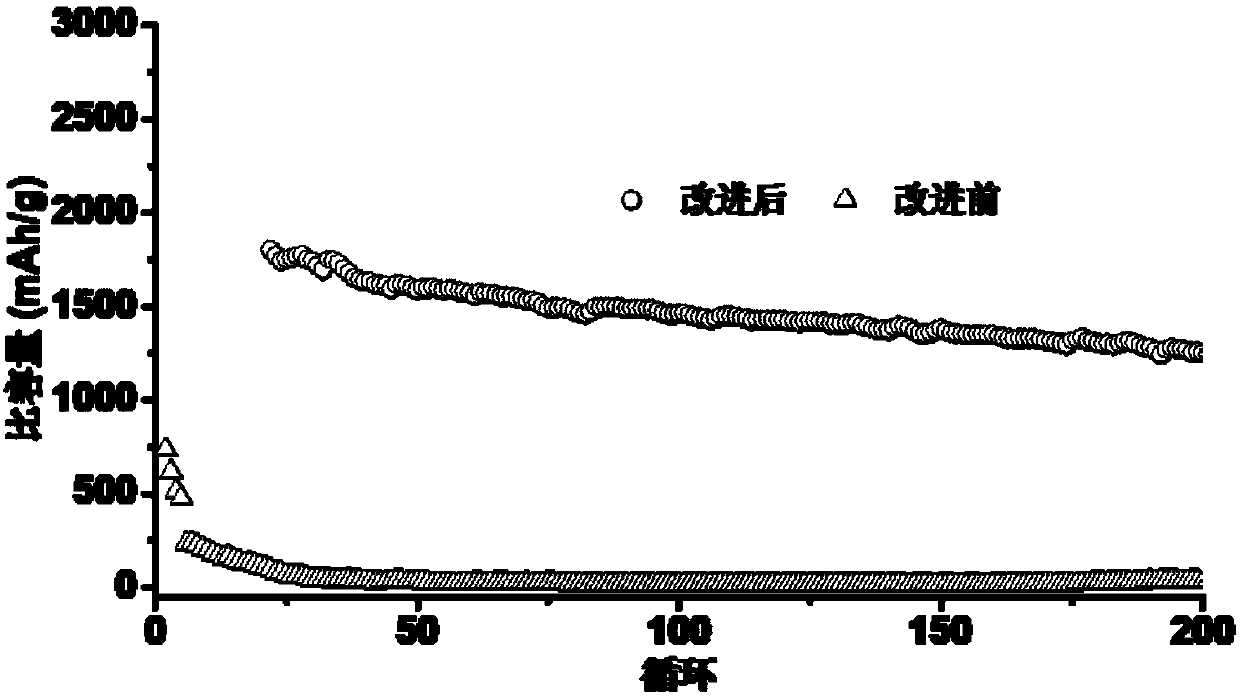

[0049] (3) Treat the electrode sheet obtained in step (2) at 300°C for 1 hour under the protection of nitrogen to obtain a carbon-coated electrode sheet, the SEM image of which is shown in figure 1 . The electrochemical performance test was carried out on the uncoated electrode sheet and the carbon-coated electrode sheet. The test results are as follows: figure 2 shown.

[0050]from figure 1 It can be seen that a layer of carbon m...

Embodiment 2

[0053] A method for coating an electrode with a composite material, comprising the following steps:

[0054] (1) Firstly, the nickel oxide nanosheets are evenly loaded on the copper grid, and after drying, the nickel oxide loading per unit area is 2mg / cm 2 electrode pads;

[0055] (2) The 20cm 2 Put the electrode sheet into a solution of dichloromethane (30ml) and pyridine (2ml) containing 5mg of compound 4, react at 60°C for 20 hours, and take out the electrode sheet;

[0056] (3) Treat the electrode sheet obtained in step (2) at 150°C for 2 hours under the protection of nitrogen to obtain a carbon-coated electrode sheet, the SEM image of which is shown in image 3 .

[0057] from image 3 It can be seen that a layer of carbon material is uniformly coated on the electrode sheet supported by nickel oxide.

Embodiment 3

[0059] A method for coating an electrode with a composite material, comprising the following steps:

[0060] (1) Firstly, the iron oxide nanorods are evenly loaded on the copper foam, and after drying, the iron oxide loading per unit area is 3mg / cm 2 electrode pads;

[0061] (2) The 15cm 2 Put the electrode sheet into a solution of diethyl ether (20ml) and tetramethylethylenediamine (1ml) containing 3mg of compound 6, react at 25°C for 20 hours, and take out the electrode sheet;

[0062] (3) Treat the electrode sheet obtained in step (2) at 120°C for 3 hours under the protection of argon to obtain a carbon-coated electrode sheet. See the SEM image of Figure 4 .

[0063] from Figure 4 It can be seen that a layer of flaky carbon material can be uniformly coated on the electrode sheet supported by iron oxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com