Transflective mode blue phase liquid crystal display

A blue-phase liquid crystal and display technology, applied in instruments, nonlinear optics, optics, etc., can solve problems such as low readability, and achieve the effect of enhancing outdoor readability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

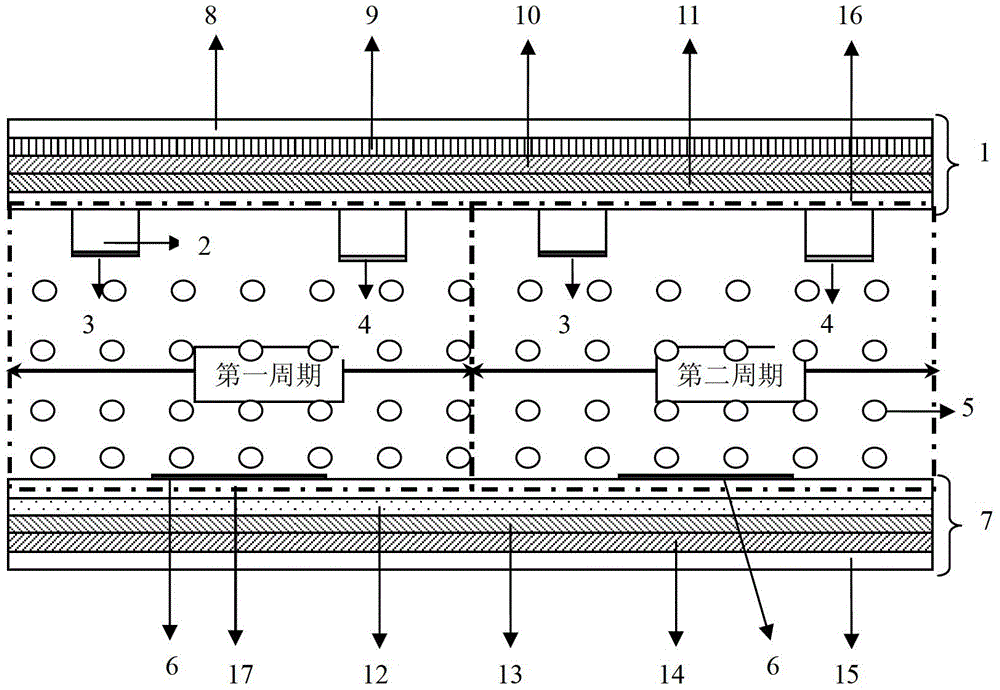

[0036] Such as figure 1 As shown, the transflective mode blue-phase liquid crystal display of the present embodiment, its composition and positional relationship from bottom to top include: the lower substrate 7, the middle part and the upper substrate 1; the lower substrate 7 includes: polarizer from bottom to top 15 , the first biaxial compensation film 14 , the first +A compensation film 13 , the first −A compensation film 12 , and the lower glass substrate 17 . The upper substrate 1 includes, from bottom to top, an upper glass substrate 16 , a second +A compensation film 11 , a second -A compensation film 10 , a second biaxial compensation film 9 and a polarizer 8 .

[0037] The middle part includes silicon dioxide (SiO 2 ) protrusions 2, first Pixel electrodes 3, second Pixel electrodes 4, blue phase liquid crystal layer 5 and aluminum electrode layer 6 used as a reflective layer; the silicon dioxide protrusions 2 are located on the upper substrate 1 The lower surface o...

Embodiment 2

[0061] Such as Figure 4 As shown, the transflective mode blue-phase liquid crystal display of the present embodiment, its composition and positional relationship from bottom to top include: the lower substrate 7, the middle part and the upper substrate 1; the lower substrate 7 includes: polarizer from bottom to top 15 , the first biaxial compensation film 14 , the first +A compensation film 13 , the first −A compensation film 12 , and the lower glass substrate 17 . The upper substrate 1 includes from bottom to top: an upper glass substrate 16, a second +A compensation film 11, a second -A compensation film 10, a second biaxial compensation film 9, and a polarizer 8

[0062] The middle part includes a first Pixel electrode 3, a second Pixel electrode 4, a silicon dioxide (SiO2) protrusion 2 and an aluminum electrode layer 6 used as a reflective electrode, wherein the blue phase liquid crystal layer 5 is filled between the two glass substrates between. The silicon dioxide pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com