SMT (surface mount technology) management and monitoring system based on wireless sensor network and GPS (global position system)

A management monitoring system, wireless sensor network technology, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems of difficult and unobstructed anti-theft monitoring, workshop environment interference, and inability to provide management methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

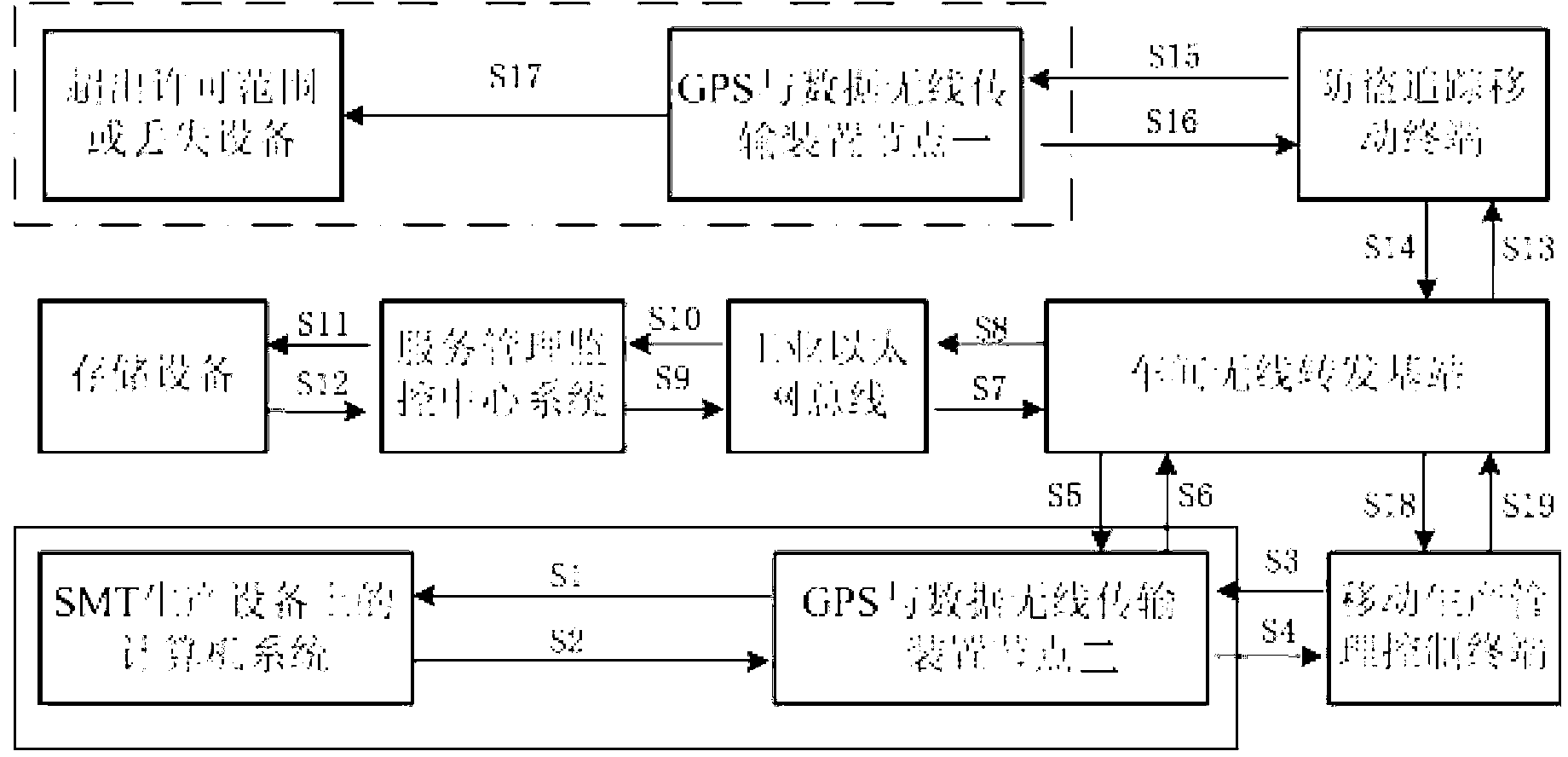

[0023] Such as figure 1 shown. The present invention is based on wireless sensor network and GPS SMT management and monitoring system, including workshop wireless forwarding base station, anti-theft tracking mobile terminal, GPS and data wireless transmission device node 1, industrial Ethernet bus, service management monitoring center system, storage equipment, mobile Production management control terminal, GPS and data wireless transmission device node 2, computer system on SMT production equipment;

[0024] The GPS and data wireless transmission device node one are connected with the anti-theft tracking mobile terminal signal;

[0025] The storage device, the service management monitoring center system, and the industrial Ethernet bus are sequentially connected by signals;

[0026] The computer system on the SMT production equipment, the GPS and the data wireless transmission device node 2, and the mobile production management control terminal are sequentially connected by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com